Method for minimizing degree of explosion of steam boiler vessel and device thereof

A steam boiler, the smallest technology, applied to steam boiler components, steam boilers, steam boiler accessories, etc., can solve problems such as high hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

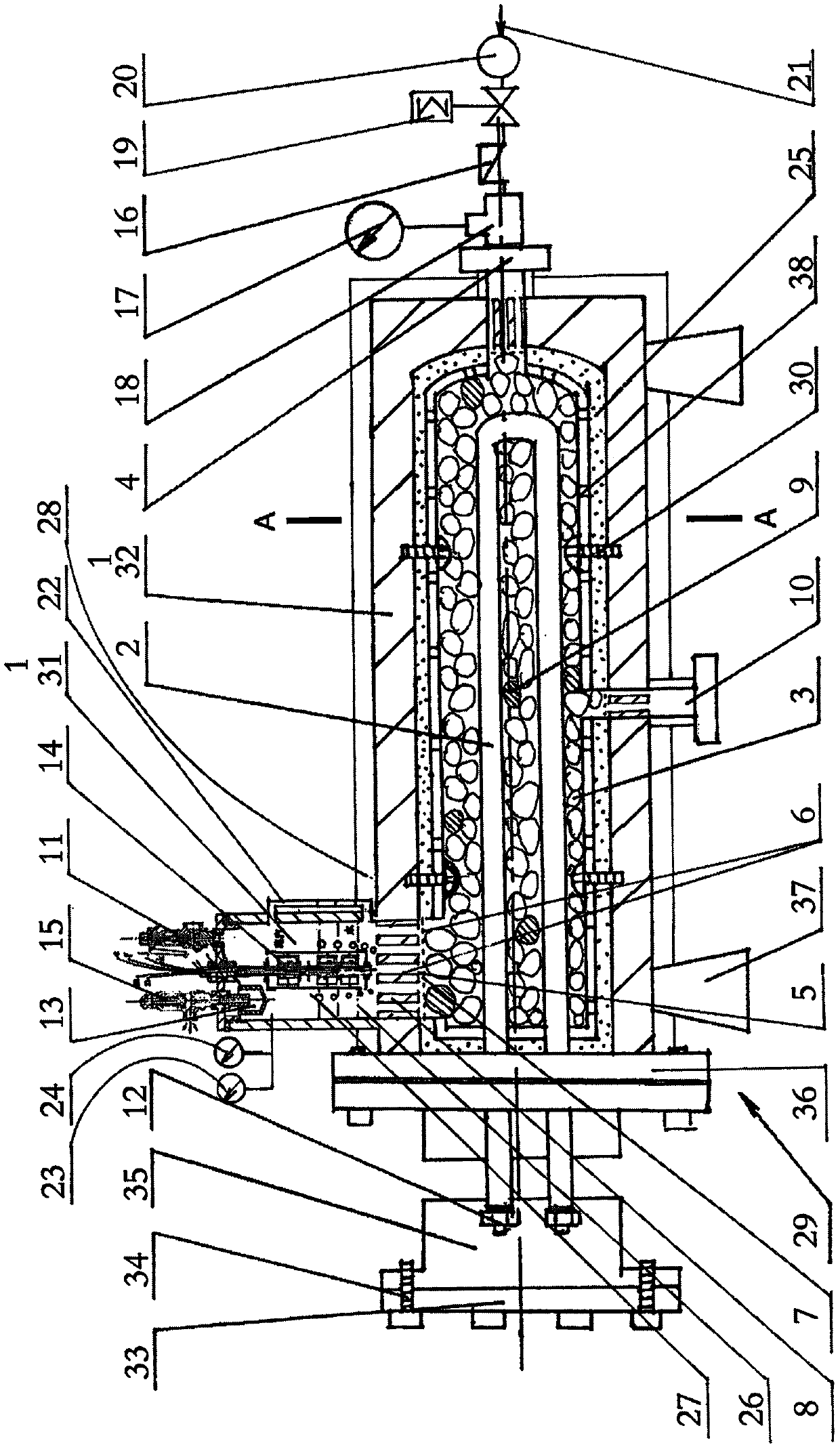

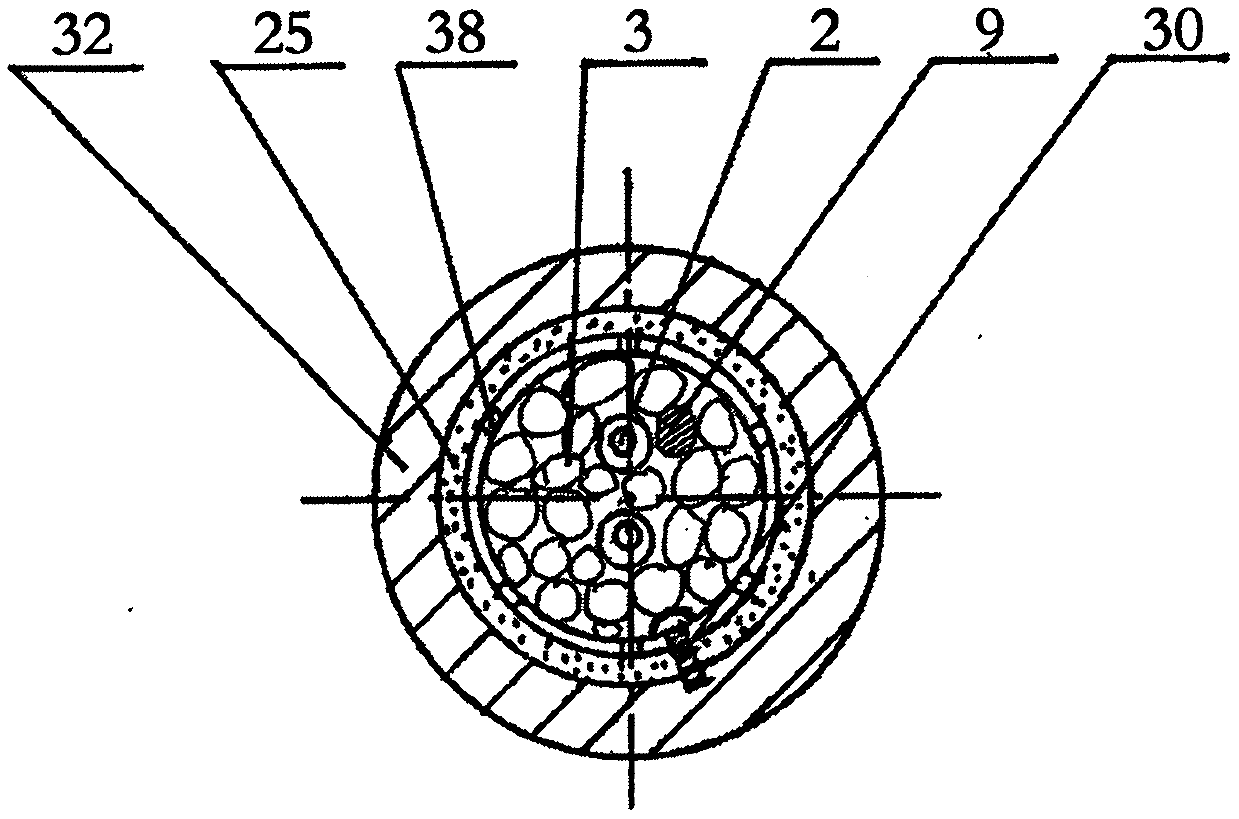

[0040] figure 1 Among them, the electric steam boiler 29 includes: a pressure vessel 1, an electric heater 2, hard solid particles 3, a water inlet 4 communicated with the pressure vessel, a steam outlet 5, or a sewage outlet 10, a fence 6, an elastic Granules or flakes 9, or soft high-temperature-resistant pressure vessel liner 25, safety valve 11, power terminal 12, steam-water separator 13, water level controller 14, pressure relief valve 15, check valve 16, or water inlet Pressure gauge 17, or tee 18, solenoid valve 19, or booster pump 20, water source 21, or water level measuring device 22, steam pressure measuring device 23, temperature measuring device 24, or insulation device 28, wherein fence 6 or by steel wire The net 7 is composed of a hard net plate 8, and it is characterized in that: at least between the inner wall of the container 32 of the heating part of the pressure vessel 1 and the electric heater 2, or filled with the inner wall of the container 32 close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com