Multiparameter oil comprehensive detection device and manufacturing method thereof

A comprehensive detection, multi-parameter technology, used in fluid pressure actuation devices, fluid pressure actuation system testing, mechanical equipment, etc., can solve problems such as insufficient detection accuracy, and achieve the effect of improving detection accuracy and strengthening magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

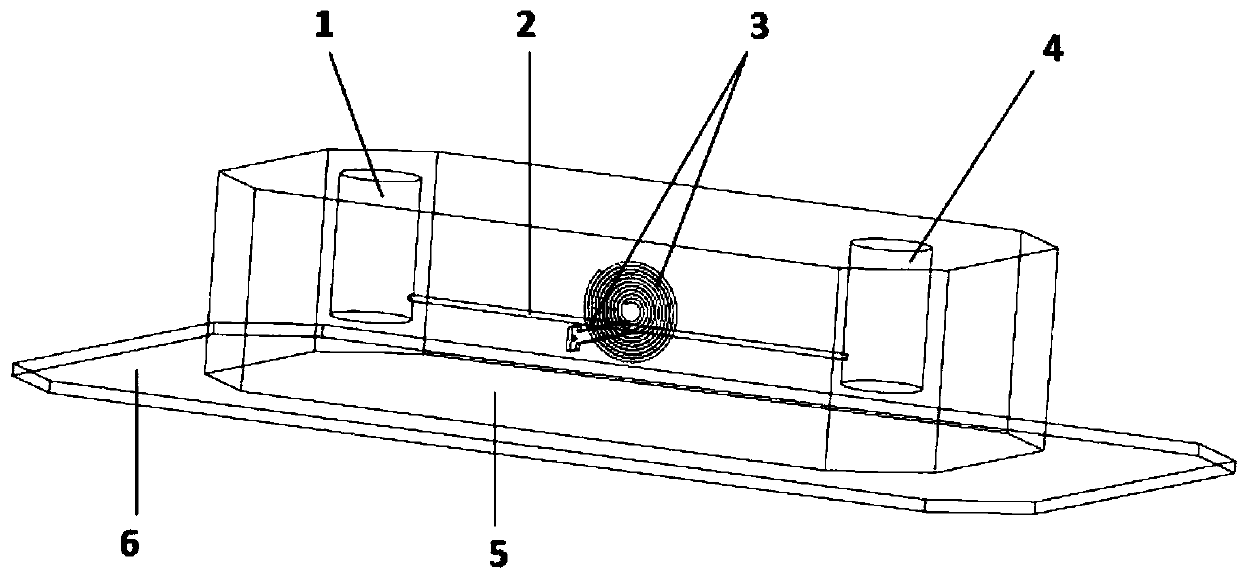

[0046] Such as figure 1 As shown, the present invention provides a multi-parameter oil comprehensive detection device including a microfluidic detection chip, a detection mode switching unit 9 and an excitation-detection unit 10; the microfluidic detection chip includes a glass substrate 6 and a A chip body; the chip body includes:

[0047] One end of the chip body is provided with a microchannel inlet 1, and the other end is provided with a microchannel 2 with a microchannel outlet 4 and a sensing unit 3; the oil with particulate pollutants is driven from the microchannel inlet 1 into the detection device, Flow through the sensing unit 3 through the microchannel 2, and finally go from the microchannel 2 to the outlet 4 of the microchannel.

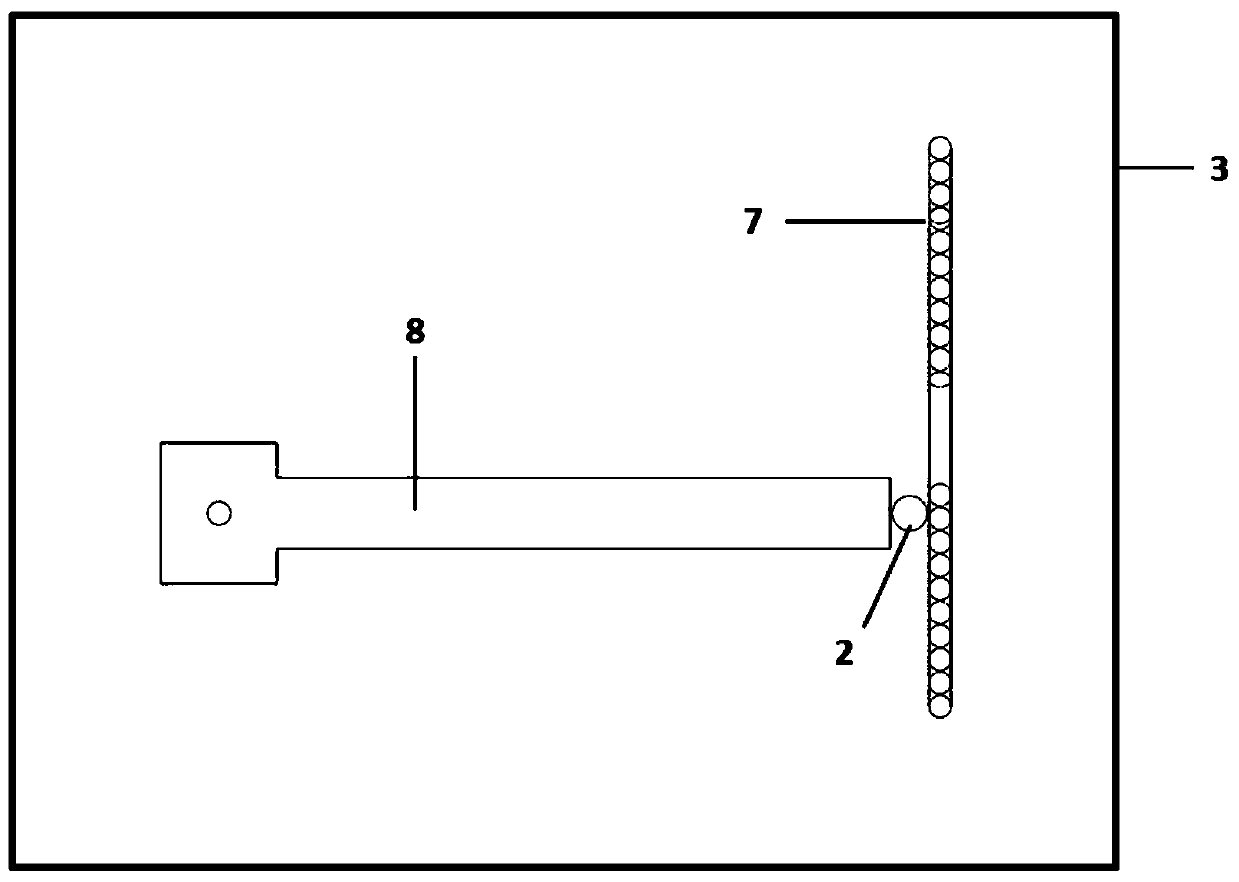

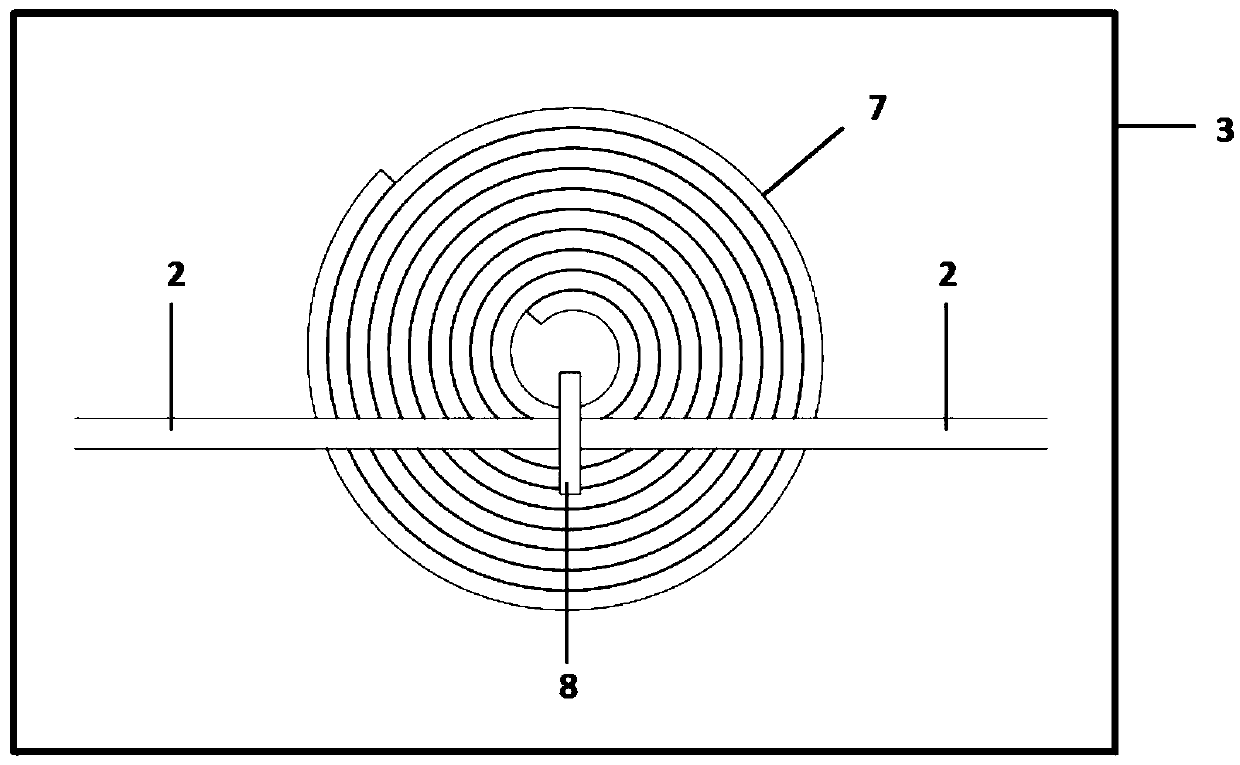

[0048] Such as Figure 2-3 As shown, the sensing unit 3 includes a planar inductance coil 7 and a strip-shaped silicon steel sheet 8; the planar inductance coil 7 and the strip-shaped silicon steel sheet 8 are placed oppositely; the mic...

Embodiment 2

[0063] Such as Figure 7 As shown, another embodiment of the present invention shows a detection comparison chart for 90-100 micron iron particles. The signal obtained by detecting 90-100 micron iron particles with a chip added with a silicon steel sheet is 9.3×10 -10 H, the signal obtained by detecting 90-100 micron iron particles on the chip without silicon steel sheet is 5.2×10 -10 H; The detection accuracy of the chip with silicon steel sheet is significantly improved compared with the chip without silicon steel sheet.

[0064] Such as Figure 8 As shown, another embodiment of the present invention shows a detection comparison chart for 190-200 micron copper particles. The signal obtained by detecting 190-200 micron copper particles with a silicon steel sheet is 7.4×10 -10 H, the signal obtained by detecting 190-200 micron copper particles on the chip without silicon steel sheet is 2.1×10 -10 H; Compared with the chip without silicon steel sheet, the detection accurac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com