Radial plunger motor rotating speed measuring and control system and method based on double-angle induction

A technology of rotational speed measurement and control system, applied in the direction of servo motor, fluid pressure actuation system test, fluid pressure actuation device, etc., can solve the problem of inability to meet the control requirements of radial variable motor, and achieve fast and stable control response speed good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

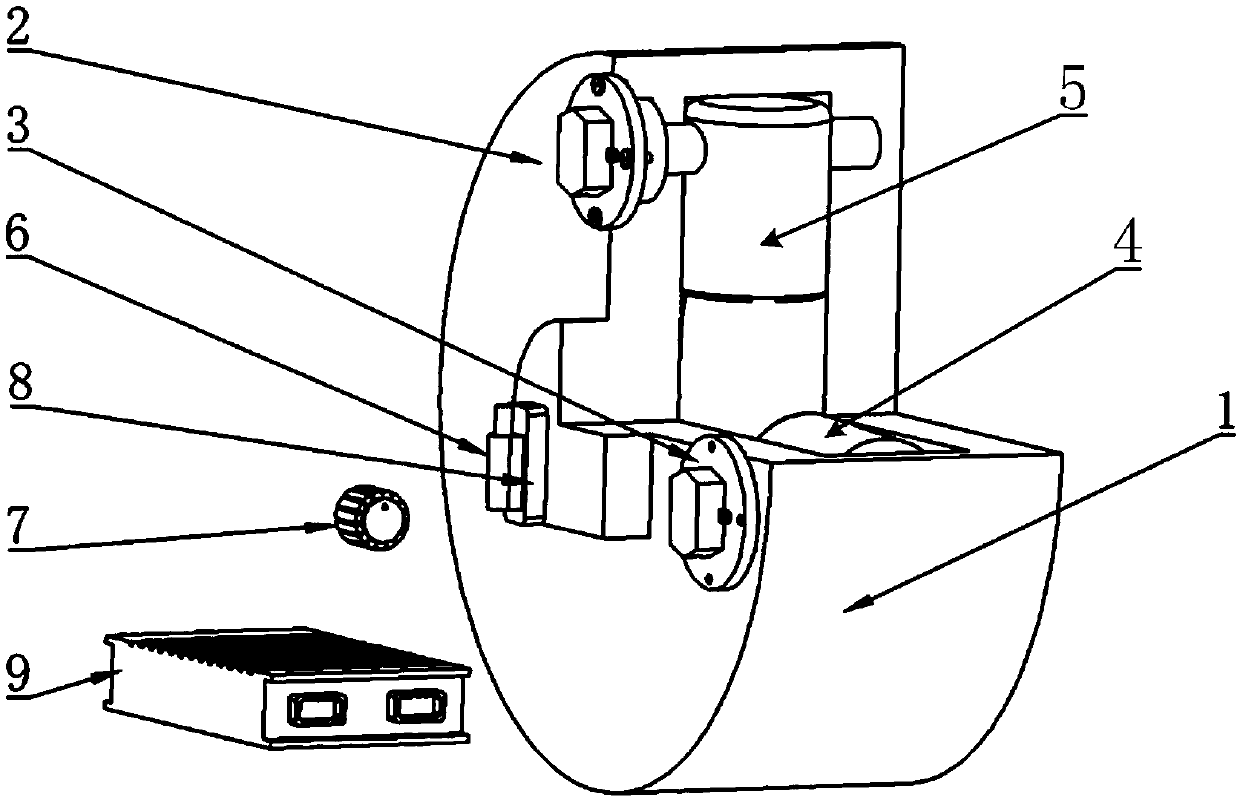

[0041] according to figure 1 The radial piston motor rotation speed measurement control system based on dual angle induction shown in the radial piston motor rotation speed measurement control system based on dual angle induction includes at least the radial piston motor 1, and also includes the radial piston motor plunger Swing angle acquisition device, rotational speed adjustment device and controller 9; said radial piston motor plunger swing angle acquisition device is connected with the plunger of radial piston motor 1, and the radial piston motor plunger swing angle acquisition device , The rotating speed adjustment device is electrically connected with the controller 9.

[0042] In actual use, the number of plungers of the radial piston motor generally has five cylinders, seven cylinders or nine cylinders. The more the number of plungers (the number is an odd number), the more stable the operation of the motor. The radial piston motor 1 is described on the basis of. Du...

Embodiment 2

[0045] according to figure 1 , Figure 9 and Figure 10 The radial piston motor rotation speed measurement and control system based on dual angle induction is different from the first embodiment in that: the radial piston motor plunger swing angle acquisition device is an angle sensor; the angle sensor Connected to the top of the plunger of the radial piston motor 1, the angle sensor is electrically connected to the controller 9.

[0046] In actual use, the radial piston motor plunger swing angle acquisition device is an angle sensor; the angle sensor is connected to the top of the radial piston motor 1 plunger, and the angle sensor and the controller 9 are connected electrically The scheme setting of the connection can conveniently and accurately collect the swing data of the plunger of the radial piston motor 1 , and transmit the collected data to the controller 9 in time.

Embodiment 3

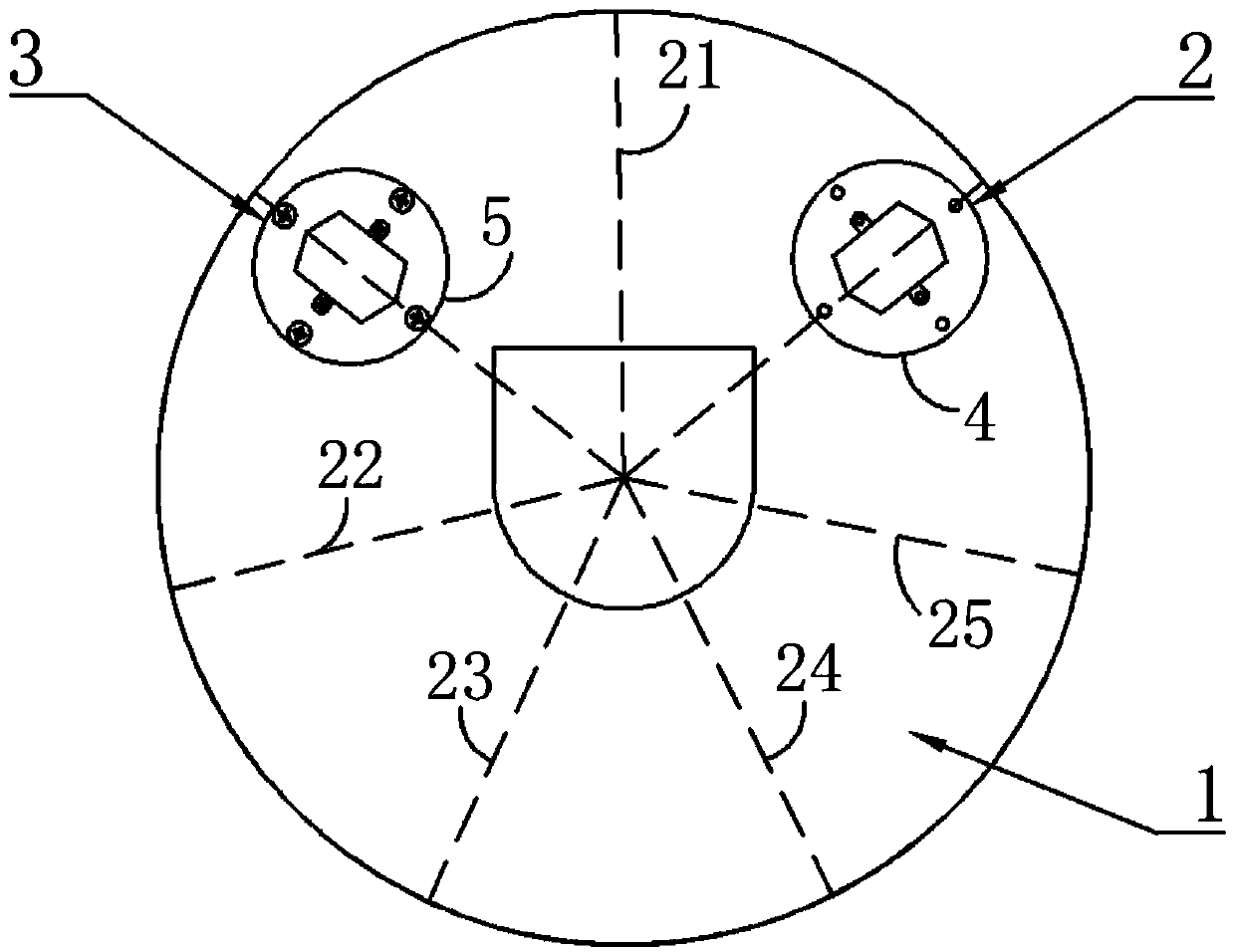

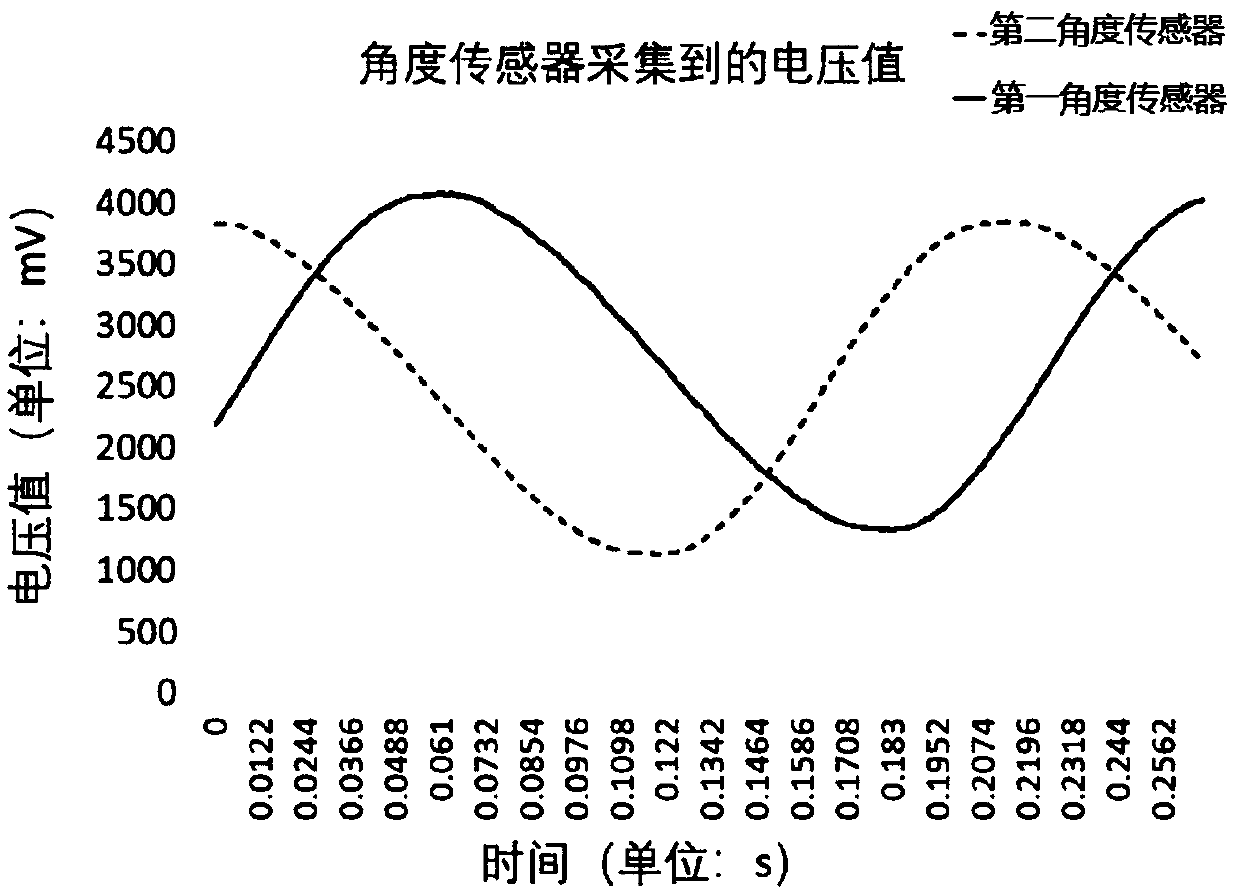

[0048] according to figure 1 , figure 2 , Figure 5-9 and Figure 11 The radial piston motor rotational speed measurement control system based on dual angle sensing differs from the second embodiment in that: there are two angle sensors, namely the first angle sensor 2 and the second angle sensor 3; The radial piston motor 1 is provided with a plurality of motor plungers, the first angle sensor 2 and the second angle sensor 3 are respectively connected to the tops of the two motor plungers, and the first angle sensor 2 and the second angle sensor 3 are connected At least one motor plunger is spaced between the two motor plungers; the first angle sensor 2 and the second angle sensor 3 are electrically connected to the controller 9 respectively.

[0049] Preferably, the first angle sensor 2 and the second angle sensor 3 are respectively connected to the rotation center of the connected motor plunger top.

[0050] Radial piston motors generally have five cylinders and seven ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com