Method for manufacturing spunlace non-woven wallpaper

A technology of spunlace non-woven fabric and manufacturing method, which is applied in the directions of textiles and papermaking, non-woven fabrics, fiber types, etc., can solve the problems of unfavorable wallpaper pattern printing, insufficient coverage, poor strength, etc., and achieves small tensile deformation. , The effect of strong covering and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

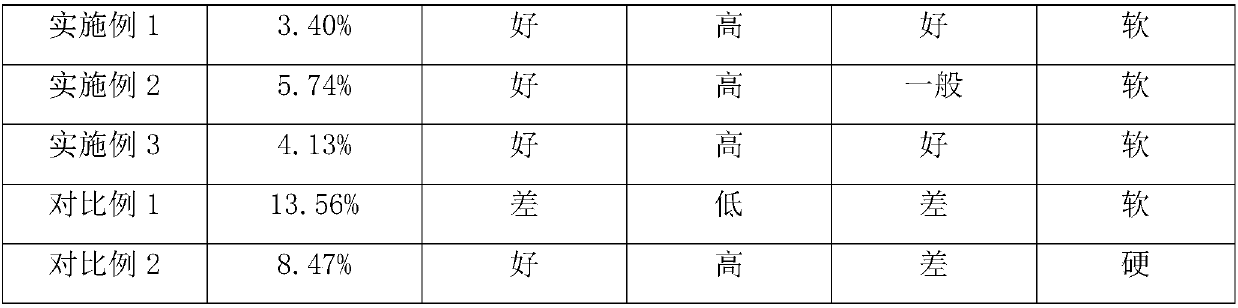

Embodiment 1

[0030] Using 30% by weight of polyester fiber filaments and 70% by weight of polyester fiber short filaments as raw materials, a spunlace nonwoven fabric is made through a spunlace process, and the spunlace pressure is 28 bar. The prepared spunlace nonwoven fabric is soaked in the padding solution, and the padding solution includes the following components in parts by weight: 20 parts of aqueous acrylic lactic acid solution, 10 parts of kaolin, 15 parts of titanium dioxide, 1 part of dispersant, and 0.5 parts of defoaming agent 0.5 parts of antifungal agent, 3.5 parts of water repellent, and 49.5 parts of water. The spunlace non-woven fabric after padding is subjected to surface coating treatment for further shaping. First use the primer medium to sizing the spunlace non-woven fabric once through a 105-mesh garden net. The primer medium includes the following ingredients in parts by weight: 15 parts of water-based acrylic emulsion, 70 parts of water, 5 parts of transparent pow...

Embodiment 2

[0032] Using 25% by weight of polyester fiber filaments and 75% by weight of polyester fiber short filaments as raw materials, a spunlace nonwoven fabric is made through a spunlace process, and the spunlace pressure is 27 bar. The prepared spunlace non-woven fabric is soaked in the padding liquid, and the padding liquid includes the following components in parts by weight: 15 parts of aqueous acrylic lactic acid solution, 5 parts of kaolin, 10 parts of titanium dioxide, 0.5 parts of dispersant, and 0.2 parts of defoaming agent 2 parts, 0.2 parts of antifungal agent, 2 parts of water repellent, 60 parts of water. The spunlace non-woven fabric after padding is subjected to surface coating treatment for further shaping. First use the primer medium to sizing the spunlace non-woven fabric once through a 105 mesh garden net. The primer medium includes the following ingredients in parts by weight: 10 parts of water-based acrylic emulsion, 75 parts of water, 3 parts of transparent pow...

Embodiment 3

[0034] Using 35% by weight of polyester fiber filaments and 65% by weight of polyester fiber short filaments as raw materials, a spunlace nonwoven fabric is made through a spunlace process, and the spunlace pressure is 30 bar. The prepared spunlace nonwoven fabric is soaked in the padding solution, and the padding solution includes the following components in parts by weight: 25 parts of water-based acrylic lactic acid solution, 15 parts of kaolin, 20 parts of titanium dioxide, 2 parts of dispersant, 1 part of defoamer 1 part, 1 part of antifungal agent, 5 parts of waterproofing agent, 40 parts of water. The spunlace non-woven fabric after padding is subjected to surface coating treatment for further shaping. First use the primer medium to sizing the spunlace non-woven fabric once through a 105-mesh garden net. The primer medium includes the following ingredients in parts by weight: 20 parts of water-based acrylic emulsion, 60 parts of water, 10 parts of transparent powder, 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com