Natural cashmere degreasing method adopting biological enzyme process

A biological enzyme method and biological enzyme technology are applied in the field of biological enzymatic degreasing of natural cashmere, which can solve the problems of non-biodegradation, flammable danger, environmental pollution, etc., and achieve the effect of in-depth degreasing effect, optimization of degreasing effect, and improvement of degreasing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

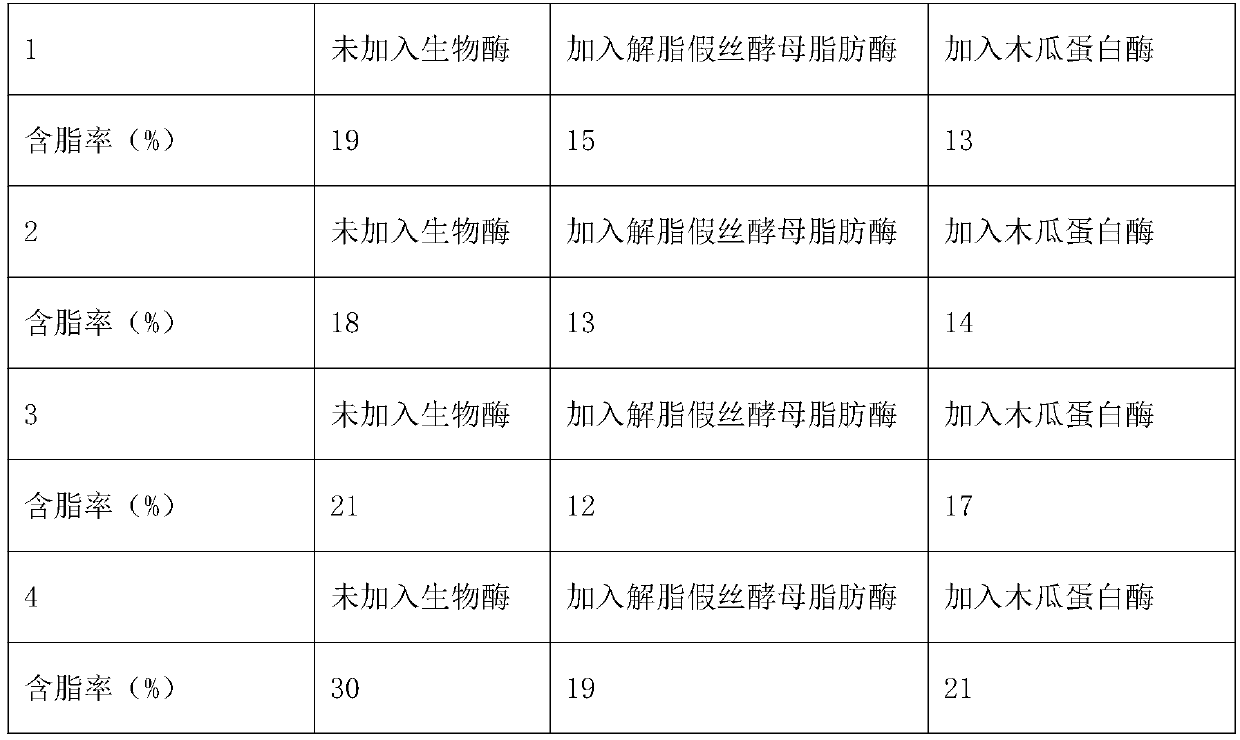

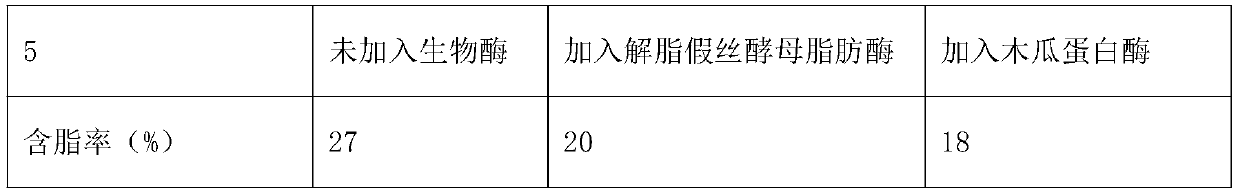

Examples

Embodiment 1

[0032] The present invention is a kind of natural cashmere bio-enzyme degreasing method, comprises the following steps:

[0033] Step 1: Remove the flesh and dust attached to the cashmere, add the cashmere to clean water, and stir to fully infiltrate the cashmere. The temperature of the soaking water is maintained at 25°C, and the soaking time is 15 minutes. Then remove the soaked cashmere and spread it with clean water Rinse for 3 minutes;

[0034] Step 2: Soak the cashmere in a weak alkaline solution with a compound degreasing agent to degrease once. The pH of the weak alkaline solution is 8, the soaking temperature is 60°C, and the soaking time is 30 minutes;

[0035] Step 3: Rinse the cashmere once with hot water, first with hot water at 60°C for 5-10 minutes, then with hot water at 45°C for 15 minutes;

[0036] Step 4: Soak the cashmere with biological enzymes in a weakly acidic solution for secondary degreasing, the pH of the weakly acidic solution is 4, the soaking tem...

Embodiment 2

[0041] The present invention is a kind of natural cashmere bio-enzyme degreasing method, comprises the following steps:

[0042] Step 1: Remove the flesh and dust attached to the cashmere, add the cashmere to clean water, and stir to fully infiltrate the cashmere. The temperature of the soaking water is maintained at 35°C, and the soaking time is 30 minutes. Rinse for 5 minutes;

[0043] Step 2: Soak the cashmere in a weak alkaline solution with a compound degreasing agent for one degreasing, the pH of the weak alkaline solution is 10, the soaking temperature is 70°C, and the soaking time is 60 minutes;

[0044] Step 3: Rinse the cashmere once with hot water, first with hot water at 60-70°C for 10 minutes, then with hot water at 55°C for 25 minutes;

[0045] Step 4: Soak the cashmere with biological enzymes in a weakly acidic solution for secondary degreasing, the pH of the weakly acidic solution is 6, the soaking temperature is 60°C, and the soaking time is 3 hours;

[0046...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com