A method for enzymatic resolution and preparation of n-methyl-d-aspartic acid

A technology for aspartic acid and enzymatic separation, applied in the field of bioengineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

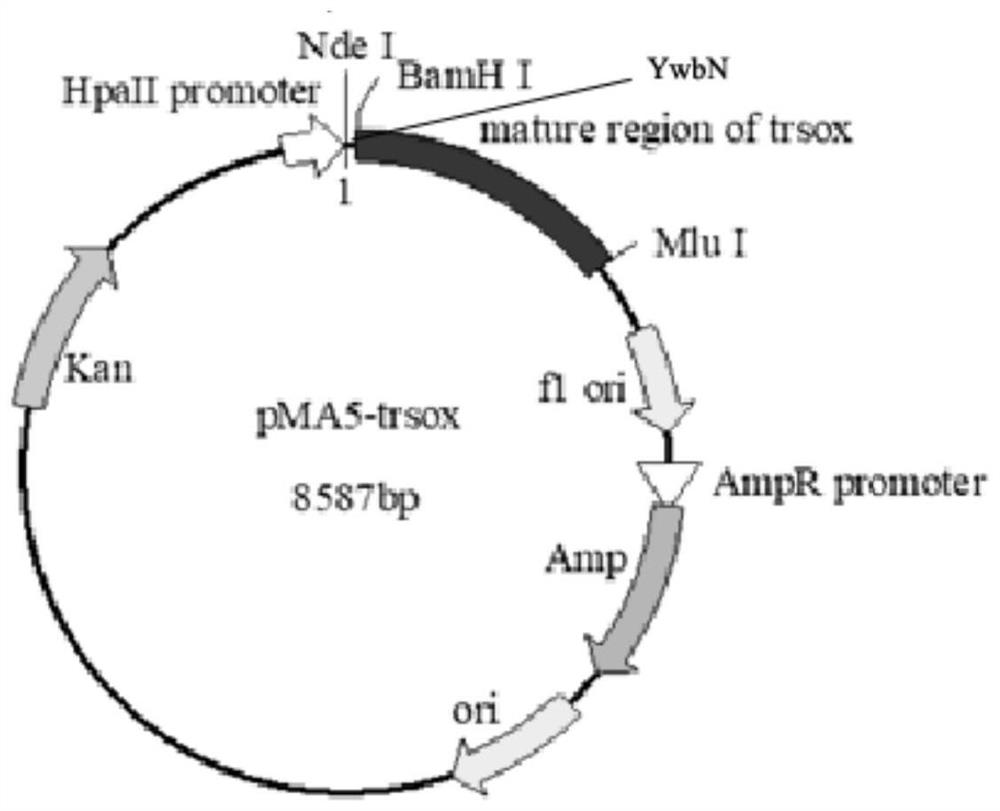

[0024] A method for preparing N-methyl-D-aspartic acid by enzymatic resolution, said method comprising the steps of:

[0025] 1) Bacillus subtilis WB600 cells transformed into the pMA5-YwbN-trsox plasmid (SEQ ID NO.1) were inserted into 5L TB medium at an inoculum size of 5%, at a temperature of 30° C., and a stirring paddle speed of 150 rpm, and cultured for 36 hours; fermentation The TrSOX activity of the liquid supernatant reached 1200U / mL;

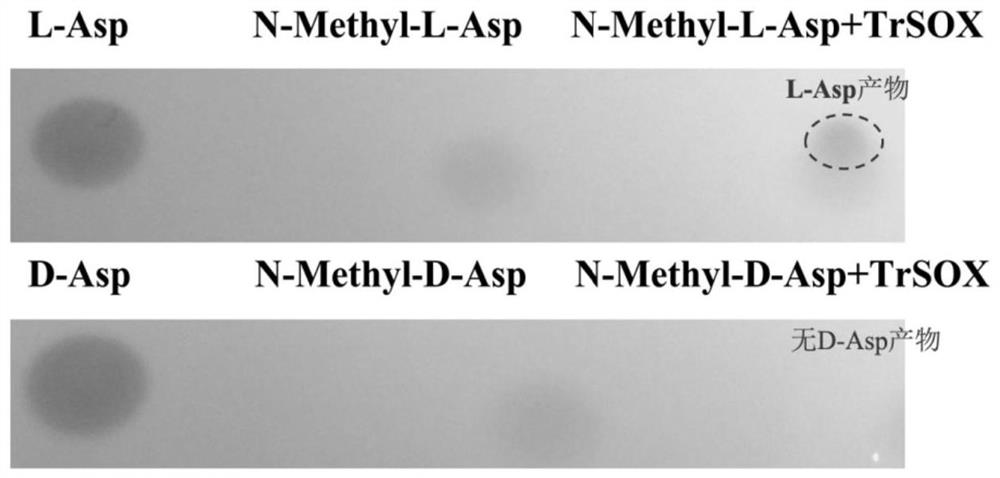

[0026] 2) Mix the above 5L of the fermentation supernatant containing 1200U / mL TrSOX with 5L of 20% N-methyl-DL-aspartic acid solution, the impeller speed is 150rpm, the pH value is maintained at 6, and the reaction temperature is maintained at 40°C, react for 12 hours, use HPLC and TLC to detect the content of N-methyl-L-aspartic acid and L-aspartic acid, the demethylation conversion rate of N-methyl-L-aspartic acid reaches About 48%.

[0027] 3) After the enzymatic conversion, 0.2% (mass volume ratio) of alum was added to flocculat...

Embodiment 2

[0029] A method for preparing N-methyl-D-aspartic acid by enzymatic resolution, said method comprising the steps of:

[0030] 1) Bacillus subtilis WB600 cells transformed into the pMA5-YwbN-trsox plasmid (SEQ ID NO.1) were inserted into 5L TB medium at an inoculum size of 5%, at a temperature of 40° C., and a stirring paddle speed of 150 rpm, and cultured for 36 hours; fermentation The TrSOX activity of the liquid supernatant reached 2100U / mL;

[0031] 2) Mix the above 5L of the fermentation supernatant containing 2100U / mL TrSOX with 5L of 20% N-methyl-DL-aspartic acid solution, the impeller speed is 150rpm, the pH value is maintained at 7, and the reaction temperature is maintained at 60°C, react for 24 hours, use HPLC and TLC to detect the content of N-methyl-L-aspartic acid and L-aspartic acid, the demethylation conversion rate of N-methyl-L-aspartic acid reaches About 80%.

[0032] 3) After the enzyme conversion is completed, add 0.3% (mass volume ratio) of alum to flocc...

Embodiment 3

[0034] A method for preparing N-methyl-D-aspartic acid by enzymatic resolution, said method comprising the steps of:

[0035]1) Bacillus subtilis WB600 cells transformed into the pMA5-YwbN-trsox plasmid (SEQ ID NO.1) were inserted into 5L TB medium at an inoculum size of 5%, at a temperature of 40° C., and a stirring blade rotating speed of 150 rpm, and cultured for 48 hours; fermentation The TrSOX activity of the liquid supernatant reached 3200U / mL;

[0036] 2) Mix the above 5L of the fermentation supernatant containing 3200U / mL TrSOX with 5L of 20% N-methyl-DL-aspartic acid solution, the impeller speed is 150rpm, the pH value is maintained at 8, and the reaction temperature is maintained at 70°C, react for 36 hours, use HPLC and TLC to detect the content of N-methyl-L-aspartic acid and L-aspartic acid, the demethylation conversion rate of N-methyl-L-aspartic acid reaches About 95%.

[0037] 3) After the enzyme conversion is completed, add 0.5% (mass volume ratio) of alum t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com