Method for improving yield and production intensity of gluconobacter oxydans sorbose

A technology for oxidizing glucose and increasing production intensity, which is applied in the field of fermentation engineering, can solve the problem of D-sorbitol forming by-products, etc., and achieve the effect of increasing production intensity and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

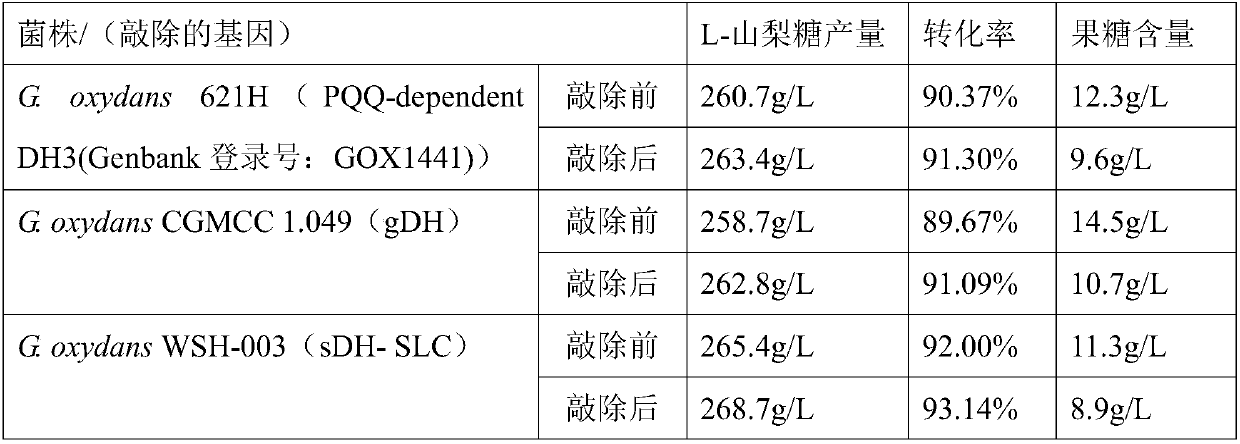

Examples

Embodiment 1

[0031] Embodiment 1: Construction of the knockout frame of gene

[0032] Use the genome of G.oxydans CGMCC 1.110 as a template to amplify the sequence of 1000bp upstream and downstream of the gene to be knocked out, and use primers to amplify the kana gene using pBBR1MCS-2 as a template, and amplify upp using the G.oxydans 1.110 genome as a template Gene, use fusion PCR to connect the above four fragments to construct a gene knockout box: left homology arm (HAL)-kana-upp-right homology arm (HAR), and connect the knockout box to pMD -19-T vector, transformed into Escherichia coli competent cells JM109, and the transformants were screened on LB plates containing ampicillin (100mg / L), sequenced, and the strains with correct sequencing were preserved.

Embodiment 2

[0033] Embodiment 2: Construction of recombinant bacteria G.oxydans-1

[0034] According to the method of Example 1, the knockout box for knocking out the GDH gene is constructed: GDHL-kana-upp-GDHR, because the dehydrogenase knockout box has kana (Genbank accession number: MH539767.1)-upp gene, will be sequenced The correct dehydrogenase knockout frame fragment was transformed into the receptor strain of Gluconobacter oxidans, CGMCC 1.110, and an upp gene-deficient strain G that grew normally in D-sorbitol medium containing kana resistance and cefoxitin was obtained .oxydans (knockout gene::kana-upp), after the first round of kana antibiotic selection, cultured in D-sorbitol containing 5-fluorouracil (300mg / L) and cefoxitin (50mg / L) The second round of screening was carried out, and the recombinant strain G.oxydans-1 with the GDH gene knocked out was obtained.

Embodiment 3

[0035] Embodiment 3: Construction of recombinant bacteria G.oxydans-2

[0036] According to the method of Example 1, the knockout box for knocking out the GA-5-DH gene was constructed: GA-5-DHL-kana-upp-GA-5-DHR, and the sequenced correct dehydrogenase knockout box fragment was converted to oxidized Gluconobacter CGMCC CGMCC 1.110 was screened by the same method as above, and the recombinant strain G.oxydans-02 with the GA-5-DH gene knocked out was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com