Waterborne acrylic acid anti-corrosion coating material containing graphene and preparation method thereof

A technology of water-based acrylic and anti-corrosion coatings, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc. It can solve the problems of water-based paints such as environmental impact, inability to cover gaps, slow drying speed, etc., and achieve high adhesion, water resistance and anti-fouling ability, dense and hard paint film, and the effect of improving drying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

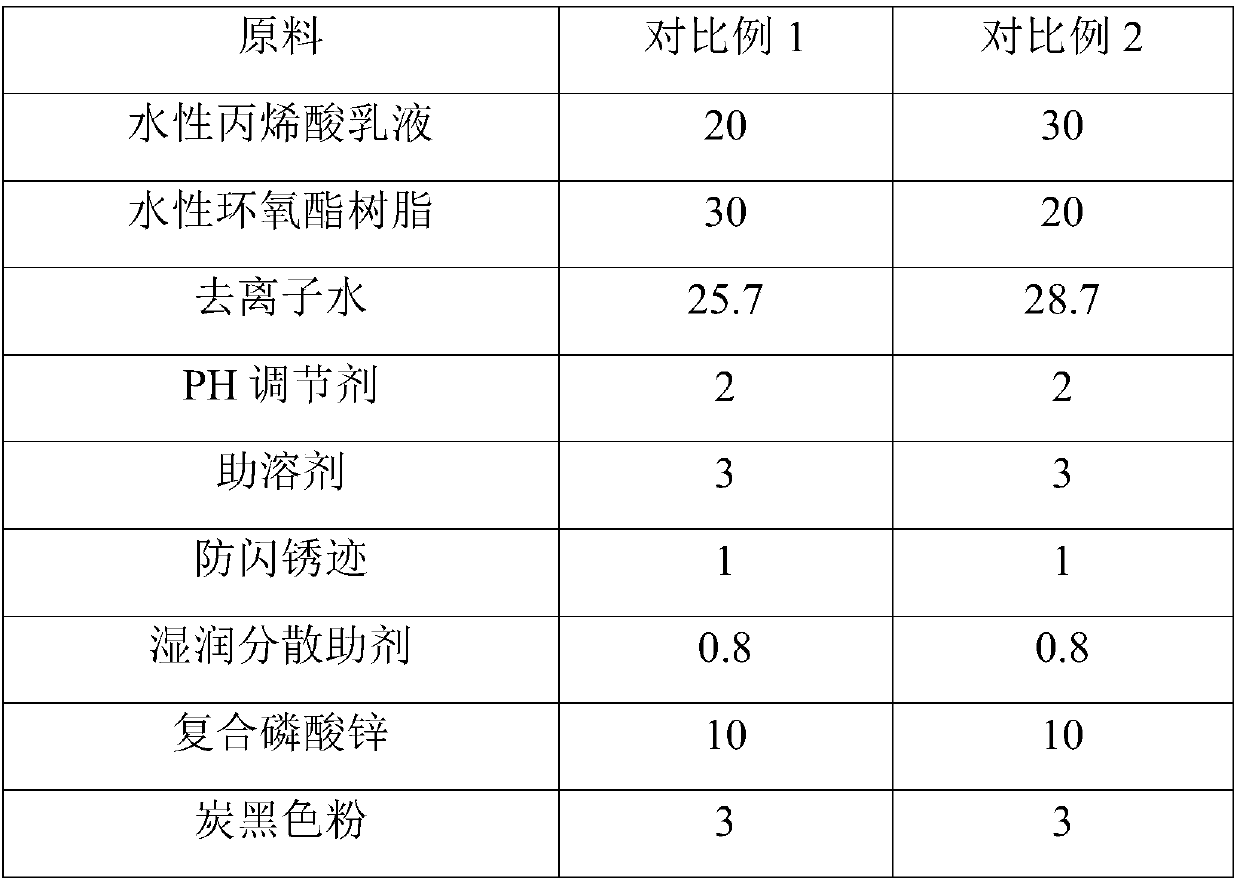

[0025] Below in conjunction with specific embodiment the present invention is described in further detail:

[0026] The mass percent of the raw material of embodiment 1~3 sees the following table:

[0027] raw material

Example 1

Example 2

Example 3

Water-Based Acrylic Emulsion

30

35

40

Waterborne Epoxy Ester Resin

20

15

10

Deionized water

25.7

22.7

18.6

PH regulator

2

1.5

1

Co-solvent

3

2.5

2

Anti-flash rust

1

1.5

2

Wetting and Dispersing Auxiliary

0.8

1

1.2

10

12

15

3

2

1

Flake graphene powder

1

2

3

thickener

0.3

0.4

0.6

0.2

0.4

0.6

Silica sol

3

4

5

Total%

100

100

100

[0028] Among the raw materials of Examples 1-3, the water-based acrylic emulsion adopts 0620 of Wanhua Chemical;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com