Preparation method of high-thermal-conductivity CNTs directed modification ceramic-based composite material

A composite material and ceramic-based technology, which is applied in the field of preparation of high-thermal-conductivity CNTs directional modified ceramic-based composite materials, can solve problems such as poor thermal conductivity, and achieve the effects of improving thermal conductivity, improving thermal conductivity, and increasing the amount of introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

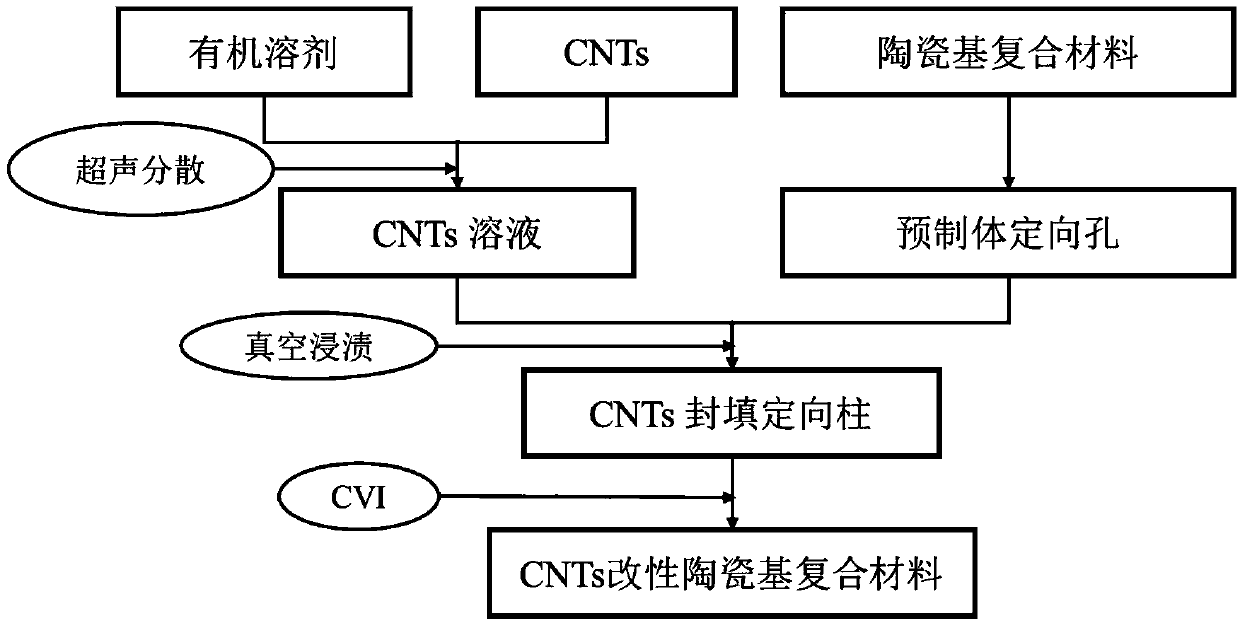

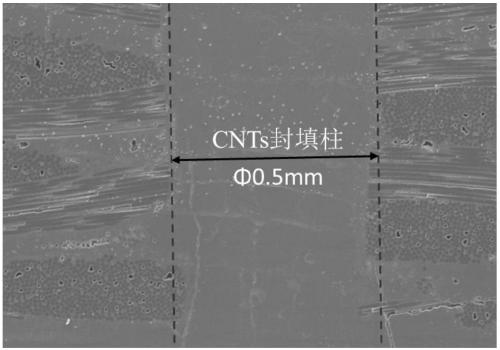

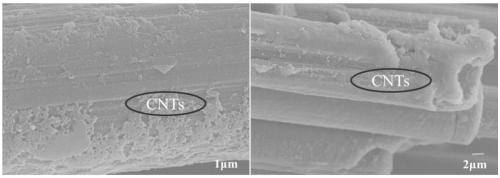

[0031] The preparation method proposed by the invention is CNTs directionally modified ceramic matrix composite material. The technical scheme of the method is: using a laser processing-assisted chemical vapor infiltration method to prepare a ceramic matrix composite material prefabricated body, and using CNTs as a second phase to seal and fill the directional holes processed in the thickness direction of the prefabricated body by vacuum impregnation. High thermal conductivity CNTs directional modified ceramic matrix composites have two major features: on the one hand, periodic CNTs directional packing columns are formed in the thickness direction of the ceramic matrix composites, increasing the amount of CNTs introduced and improving thermal conductivity; on the other hand, CNTs disperse and infiltrate The surface of the fiber bundle or fiber filament of the ceramic matrix composite forms a continuous heat conduction network in the direction of the interlayer and the inner lay...

Embodiment 1

[0041] CNTs modified density is 1.40g / cm 3 C / SiC composite materials, the specific process is:

[0042] (1) The preparation density is 1.40g / cm 3 The prefabricated body: T300-1K carbon fiber is used to weave two-dimensional plain weave cloth, and after superimposing 24 layers of stitching, the volume density is 0.74g / cm 3 1. A carbon fiber prefabricated body with a carbon fiber volume fraction of 33.0%. The preform was placed in a CVI vacuum furnace with a deposition temperature of 900°C, an atmosphere pressure of 0.2KPa, a propylene flow rate of 30ml / min, and an Ar flow rate of 300ml / min to prepare a pyrolytic carbon interface layer (PyC) with a pyrolysis thickness of about 200nm. Place the preform in a CVI vacuum furnace with a deposition temperature of 1100°C and an atmosphere pressure of 2KPa, H 2 The flow rate is 200ml / min, the Ar flow rate is 300ml / min, the temperature is naturally lowered after 200-230 hours of deposition, and the density of the prepared shape is 1.4...

Embodiment 2

[0049] CNTs modified density is 1.80g / cm 3 C / SiC composite materials, the specific process is:

[0050] (1) The preparation density is 1.80g / cm 3 The prefabricated body: T300-1K carbon fiber is used to weave two-dimensional plain weave cloth, and after superimposing 24 layers of stitching, the volume density is 0.74g / cm 3 1. A carbon fiber prefabricated body with a carbon fiber volume fraction of 33.0%. The preform was placed in a CVI vacuum furnace with a deposition temperature of 900°C, an atmosphere pressure of 0.2KPa, a propylene flow rate of 30ml / min, and an Ar flow rate of 300ml / min to prepare a pyrolytic carbon interface layer (PyC) with a pyrolysis thickness of about 200nm. Place the preform in a CVI vacuum furnace with a deposition temperature of 1100°C and an atmosphere pressure of 2KPa, H 2 The flow rate is 200ml / min, the Ar flow rate is 300ml / min, the temperature is naturally lowered after 300-400 hours of deposition, and the density of the prepared shape is 1.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com