A kind of production process of alkali-free glass fiber yarn

An alkali-free glass fiber and glass fiber yarn technology is applied in the field of glass fiber yarn, which can solve the problems of poor shear resistance and corrosion resistance, weak high temperature resistance of glass fiber, and difficulty in meeting the requirements, and achieves shear resistance and corrosion resistance. The effect of strong performance, excellent physical properties and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

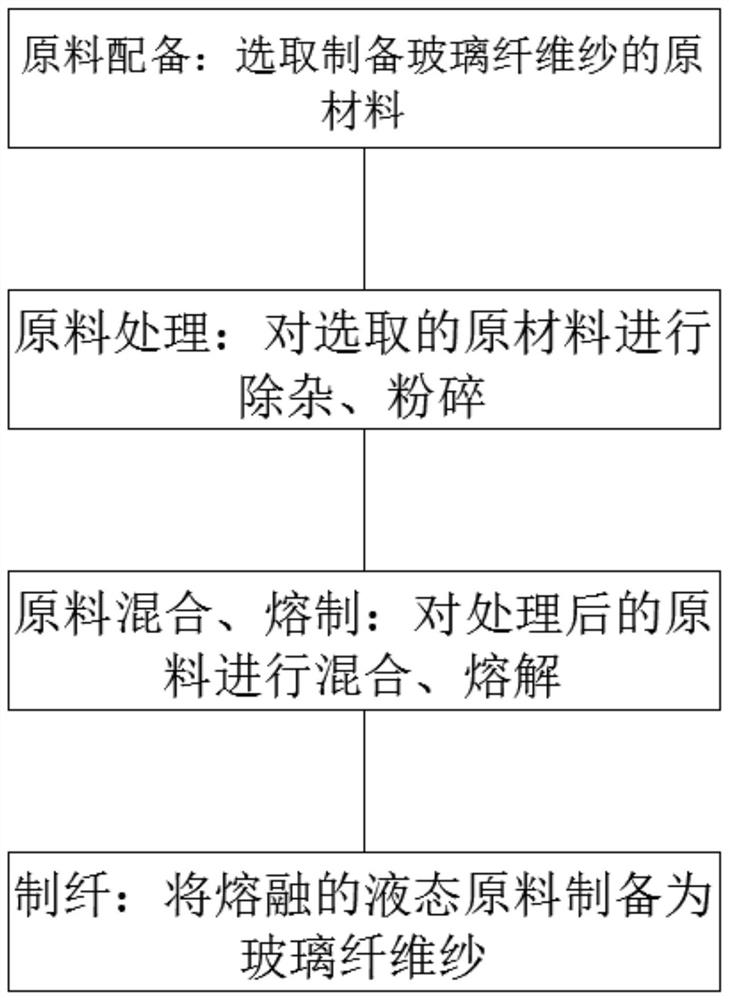

[0055] like figure 1 shown, including the following steps:

[0056] (1), raw material allocation: select the raw material for preparing glass fiber yarn;

[0057] (2), raw material processing: carry out impurity removal and pulverization to the selected raw materials;

[0058] (3), mixing and melting of raw materials: mixing and melting the treated raw materials;

[0059] (4) Fiber making: the molten liquid raw material is prepared into glass fiber yarn.

[0060] Preferably, the raw materials in the step (1) include a combination of silicon dioxide, boron oxide and metal oxides, wherein the metal oxides are mixed with magnesium oxide and aluminum oxide in a ratio of 1:1.

[0061] Preferably, in the step (2), the raw materials are treated, and the specific steps are as follows:

[0062] (2.1), the raw material in the step (1) is added in the impurity removal machine and carries out impurity removal;

[0063] (2.2), adding the raw material after the impurity removal into th...

Embodiment 2

[0075] Include the following steps:

[0076] (1), raw material allocation: select the raw material for preparing glass fiber yarn;

[0077] (2), raw material processing: carry out impurity removal and pulverization to the selected raw materials;

[0078] (3), mixing and melting of raw materials: mixing and melting the treated raw materials;

[0079] (4) Fiber making: the molten liquid raw material is prepared into glass fiber yarn.

[0080] Preferably, the raw materials in the step (1) include a combination of silicon dioxide, boron oxide and metal oxide, wherein the metal oxide is magnesium oxide.

[0081] Preferably, in the step (2), the raw materials are treated, and the specific steps are as follows:

[0082] (2.1), the raw material in the step (1) is added in the impurity removal machine and carries out impurity removal;

[0083] (2.2), adding the raw material after the impurity removal into the pulverizer and pulverizing;

[0084] (2.3) Pass the crushed raw material...

Embodiment 3

[0095] like figure 1 shown, including the following steps:

[0096] (1), raw material allocation: select the raw material for preparing glass fiber yarn;

[0097] (2), raw material processing: carry out impurity removal and pulverization to the selected raw materials;

[0098] (3), mixing and melting of raw materials: mixing and melting the treated raw materials;

[0099] (4) Fiber making: the molten liquid raw material is prepared into glass fiber yarn.

[0100] Preferably, the raw materials in the step (1) include a combination of silica, boron oxide and metal oxide, wherein the metal oxide is alumina.

[0101] Preferably, in the step (2), the raw materials are treated, and the specific steps are as follows:

[0102] (2.1), the raw material in the step (1) is added in the impurity removal machine and carries out impurity removal;

[0103] (2.2), adding the raw material after the impurity removal into the pulverizer and pulverizing;

[0104] (2.3) Pass the crushed raw m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com