Band-shaped object cutting device and band-shaped object heating device

A technology of cutting device and strip, applied in the directions of sending objects, transportation and packaging, thin material processing, etc., can solve the problems of weakening the force of restoring the straight posture, eliminating the difficulty of bending parts, and achieving the effect of eliminating bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

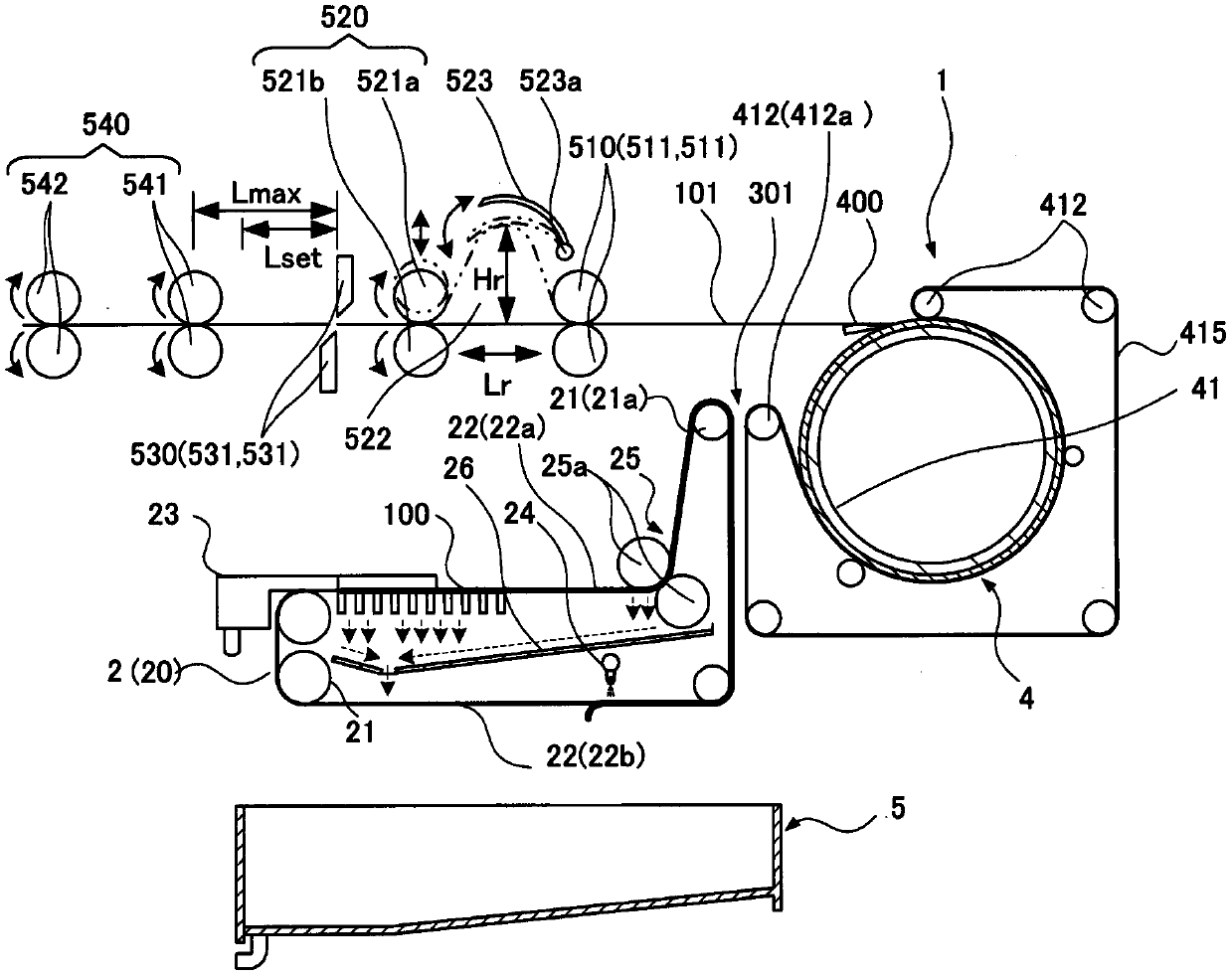

[0028] Embodiments of the present invention will be described below with reference to the drawings. exist figure 1 Among them, the waste paper processing device 1 as a kind of paper machine is equipped with: a papermaking device 2, which performs a papermaking process of making a strip-shaped wet paper 100; a drying device 4, which performs drying of the strip-shaped wet paper 100 The drying process; the white water storage part 5, the upper part of which is open, stores the filtrate flowing out from the papermaking process; and the control device controls each part (illustration omitted).

[0029] The waste paper processing apparatus 1 may provide a dehydration process between a papermaking process and a drying process. The dehydration process includes a dehydration belt made of felt. In addition, in this embodiment, the webs of the wet paper 100 and the desiccated paper 101 obtained by papering the pulp suspension will be described as an example. The ribbon-shaped article...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com