Installation process of the shock absorber for the topside module of the floating production storage and offloading unit

A technology of floating production and installation technology, which is applied to ship components, transportation and packaging, and ship construction, etc. It can solve the problems of poor stability of upper module equipment, low positioning accuracy and operating efficiency of upper modules, and no shock absorption performance To achieve the effect of improving positioning accuracy and operating efficiency, solving the problems of installation accuracy and operating efficiency, and improving shock absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Such as Figure 1-1 to Figure 9 Shown, the present invention adopts following steps:

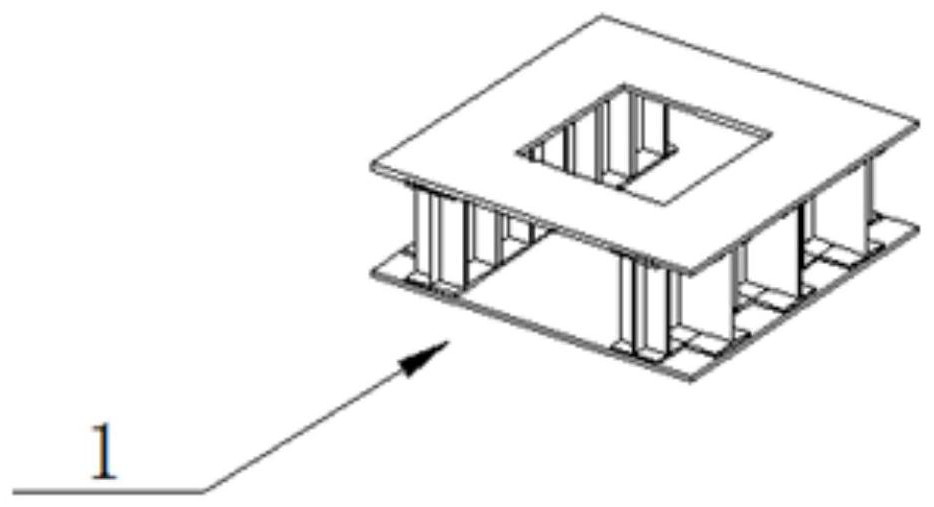

[0032] The first step: if Figure 1-1 to Figure 1-2 As shown, the hollow pier 1 is placed on the ground, the hollow pier 1 is hollow, and is used for installing the upper backing plate of the shock absorber;

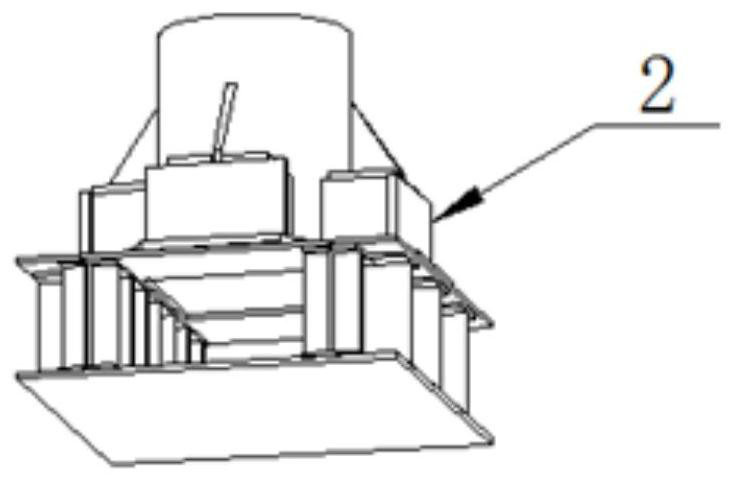

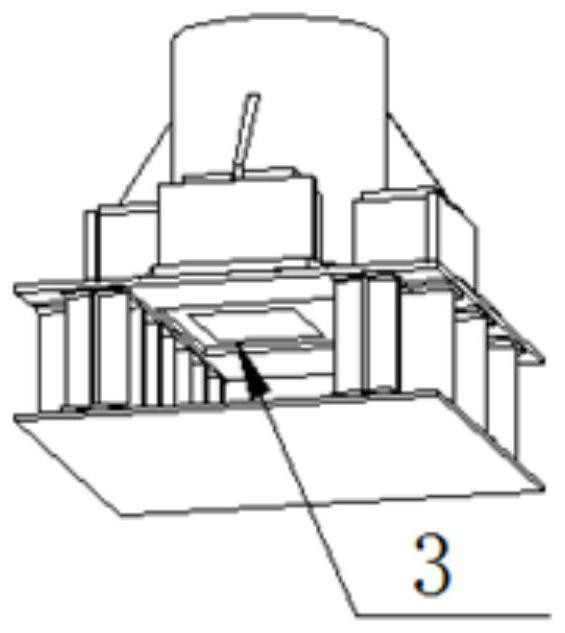

[0033] The second step: if figure 2 As shown, the upper module is placed on the hollow pier 1, and then the shock absorber upper backing plate 3 is installed on the lower bottom surface of the upper module column base 2 by intermittent welding; wherein, the shock absorber upper backing plate 3 It needs to be processed by machining to ensure that its flatness meets the requirements of use;

[0034] Step 3: If Figure 4 As shown, measure the spacing between the hull bases 4 and the spacing between the upper module column bases 2, and balance the tolerances of the upper module column bases 2 and hull bases 4 to determine the center of each upper module column base 2 An anchor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com