A phosphate glass laser cutting process

A phosphate glass, laser cutting technology, used in laser welding equipment, manufacturing tools, metal processing equipment, etc., to improve the effect of expanding grain, good cutting effect, and reduce edge chipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0018] The invention provides a phosphate glass laser cutting process, comprising the following steps:

[0019] (1) Set an appropriate depth of cut to ensure that the fault is centered;

[0020] (2) Use a low-power laser to make dots at the location of the fault;

[0021] (3) Normal cutting with proper power;

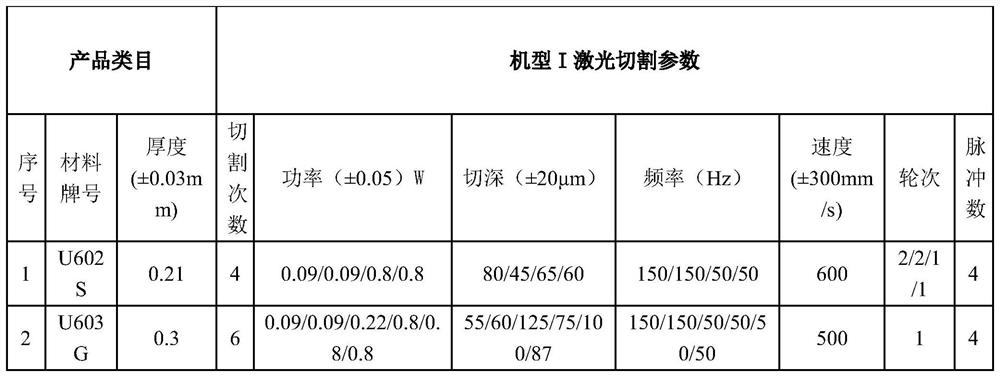

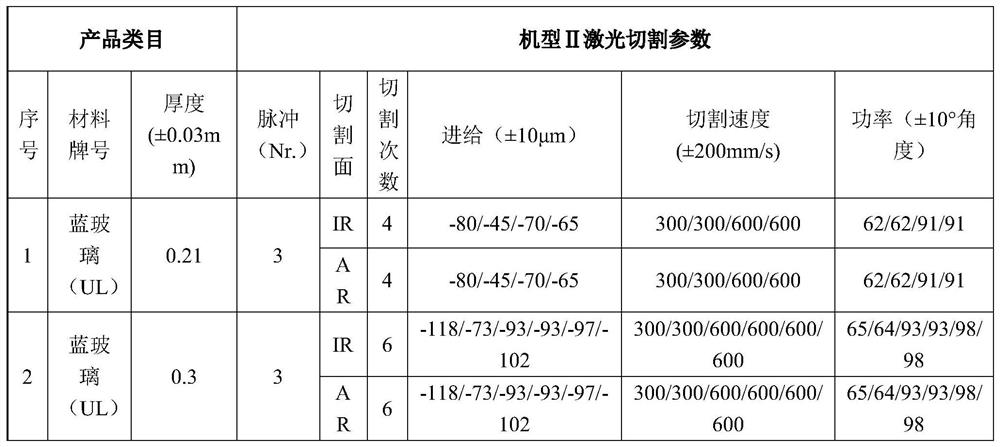

[0022] Preferably, the laser cutting parameters include: laser, power or angle, pulse number, cutting times, cutting depth or feed, cutting speed, frequency, and rounds. figure 1 with figure 2 The laser cutting parameters of the two models are given, and the laser cutting parameters can be adjusted appropriately for different cutting materials and models.

[0023] Preferably, the laser is a 1064nm frequency-doubled 532nm laser...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com