Turning processing clamp used for outer threaded joint of water-resisting guide tube

A technology of external threaded joints and risers, applied in the direction of chucks, etc., can solve the problems of inappropriate three-jaw self-centering chucks, reducing turning efficiency and safety, unstable workpiece machining positions, etc., to improve turning efficiency. and turning quality, enhanced rigidity, easy to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

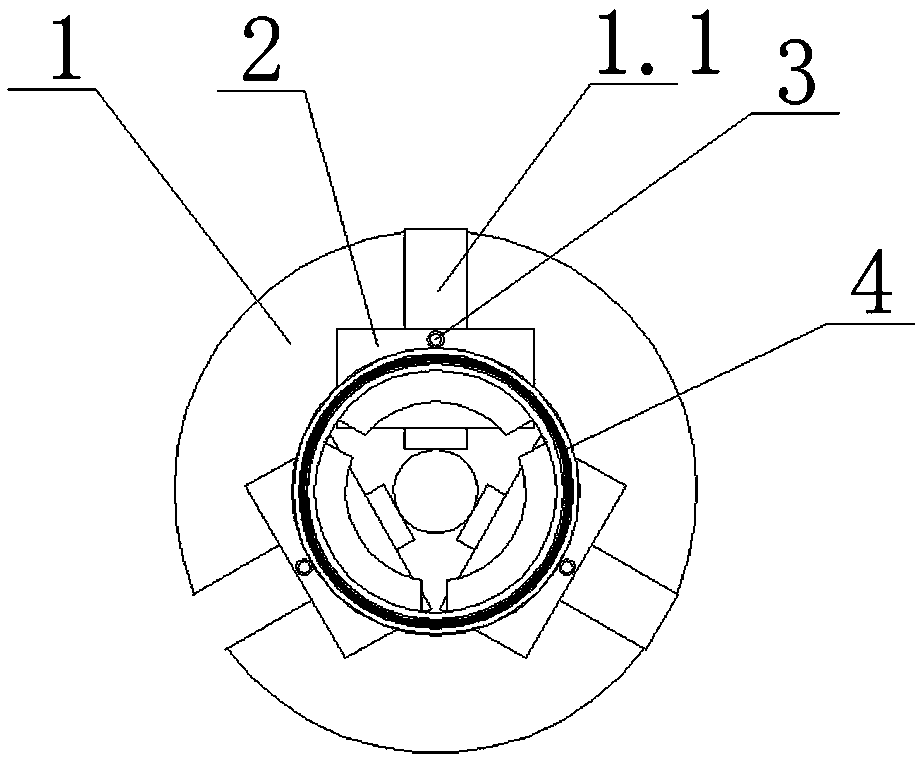

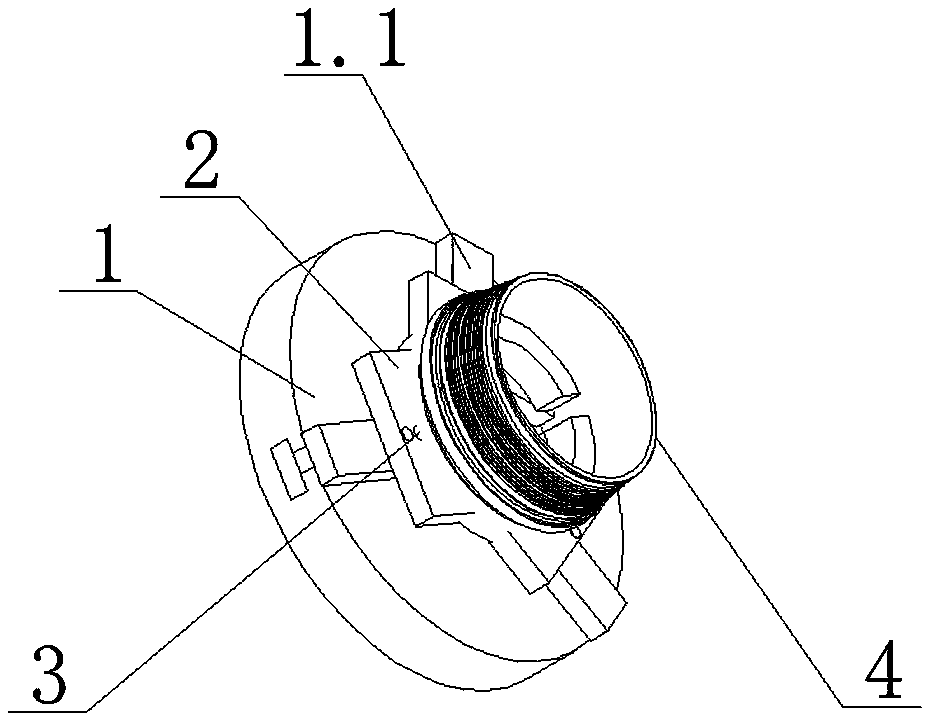

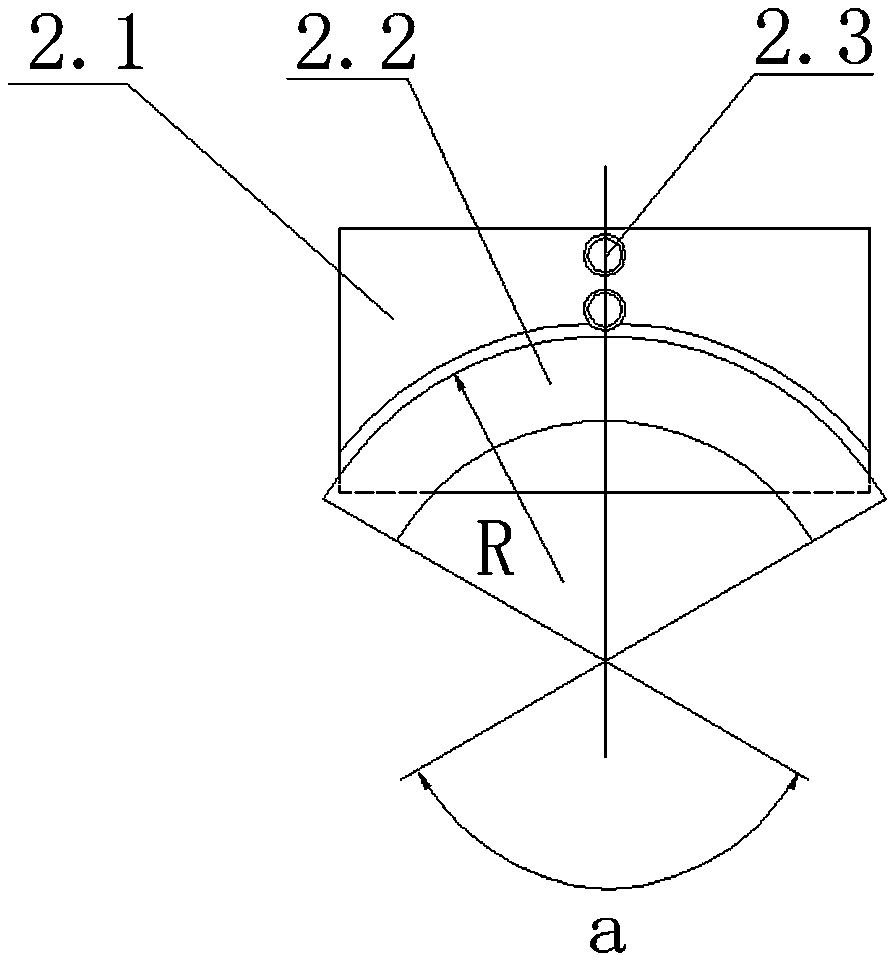

[0019] figure 1 and figure 2 Shown is a turning fixture for external threaded joints of water risers, which consists of a three-jaw self-centering chuck 1, inner jaws 2 and bolts 3. The outer end surface of the claws 1.1 matched with the three-jaw self-centering chuck 1 is a plane, and the three uniformly distributed claws 1.1 are on the same plane, and the plane is perpendicular to the axis. The inner jaw 2 is a special-shaped part, which is composed of a rectangular bottom plate 2.1 and a section of arc-shaped boss 2.2 facing inward. The arc boss 2.2 configured by the inner jaw 2 is directly against the inner wall of the workpiece 4. In order to further improve the rigidity of the workpiece 4 at the installation position, the radius R of the outer circle of the arc boss 2.2 configured by the inner jaw 2 is equal to the inner hole of the workpiece 4 to be processed. Half of the diameter, the workpiece 4 of this embodiment is an 18-inch water-resistance conduit, and its inn...

Embodiment 2

[0021] figure 1 and figure 2 Shown is a turning fixture for external threaded joints of water risers, which consists of a three-jaw self-centering chuck 1, inner jaws 2 and bolts 3. The outer end surface of the claws 1.1 matched with the three-jaw self-centering chuck 1 is a plane, and the three uniformly distributed claws 1.1 are on the same plane, and the plane is perpendicular to the axis. The inner jaw 2 is a special-shaped part, which is composed of a rectangular bottom plate 2.1 and a section of arc-shaped boss 2.2 facing the same direction. The arc boss 2.2 configured by the inner jaw 2 is directly against the inner wall of the workpiece 4. In order to improve the installation rigidity of the workpiece 4, the radius R of the outer circle of the arc boss 2.2 configured by the inner jaw 2 is equal to half the diameter of the inner hole of the workpiece 4 to be processed. Example Workpiece 4 is a 40-inch water-resistance conduit with an inner hole diameter of 1016mm, so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com