A flat glass decontamination device

A flat glass, vertical technology, applied in the direction of dry gas arrangement, cleaning method using liquid, cleaning flexible objects, etc., can solve the problems of glass pollution, reduce glass cleanliness, inconvenient cleaning, etc. The effect of decontamination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

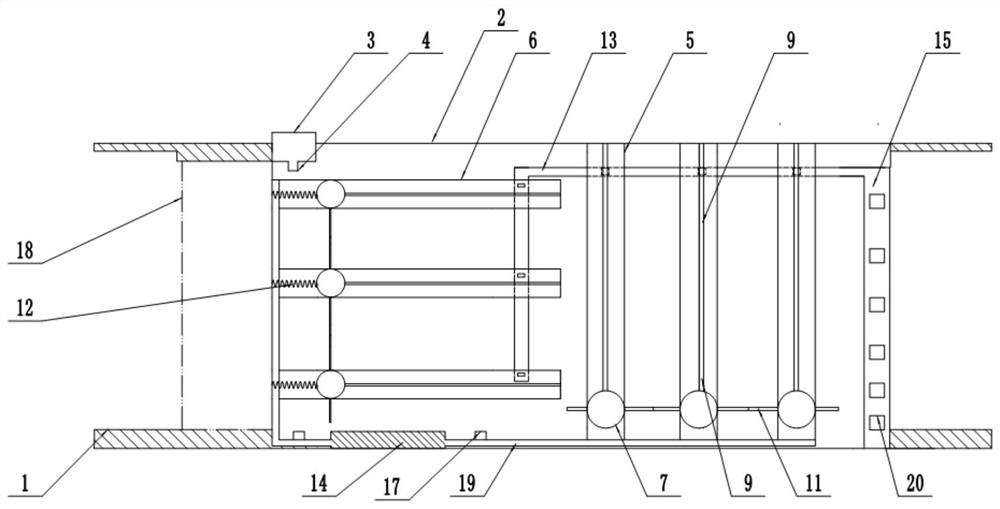

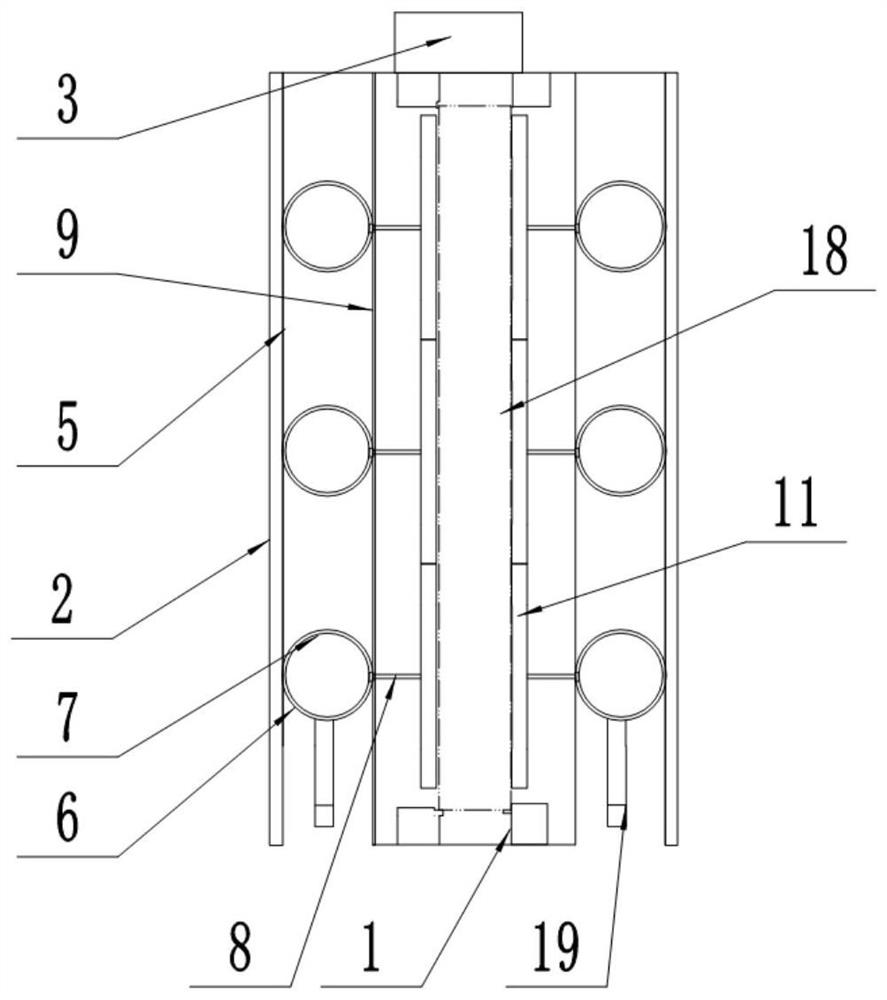

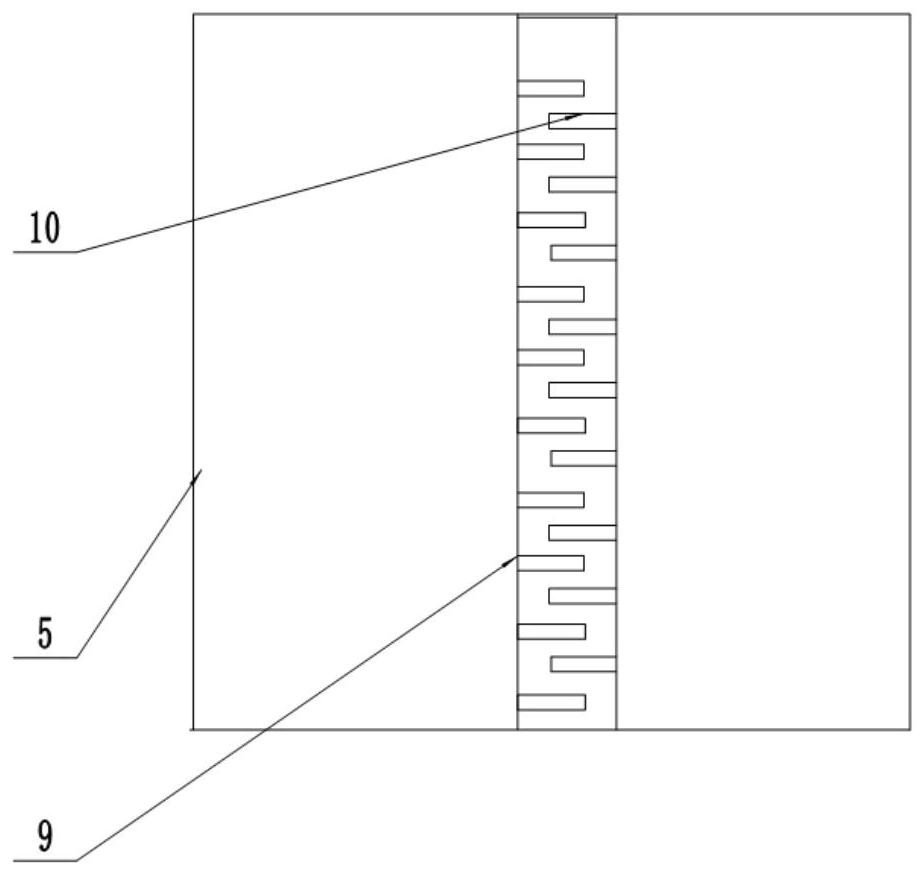

[0021] The reference signs in the drawings of the description include: slide rail 1, casing 2, water pump 3, outlet pipe 4, vertical pipe 5, horizontal pipe 6, rolling ball 7, connecting rod 8, through groove 9, felt 10, cleaning Wipe 11, spring 12, air induction pipe 13, air pump 14, air outlet pipe 15, stop valve 17, flat glass 18, air pipe 19, air outlet 20.

[0022] The embodiment is basically as attached figure 1 , figure 2 with image 3 Shown:

[0023] The orientation words such as "left, right" described in this embodiment are only limited to the appended figure 1 with figure 2 , a flat glass decontamination device, such as figure 1 As shown, including the casing 2, the bottom and the top of the casing 2 are equipped with horizontal slide rails 1, and the slide rails 1 are used to transport large-area flat glass 18 to be decontaminated. A decontamination area and a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com