Ophiopogon japonicas drying method

A processing method, the technology of Ophiopogon japonicus, applied in the direction of drying gas arrangement, drying, drying machine, etc., can solve the problems of low processing efficiency and poor quality of Ophiopogon japonicus, reduce the loss of nutrients, The effect of improving efficiency and improving elutriation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

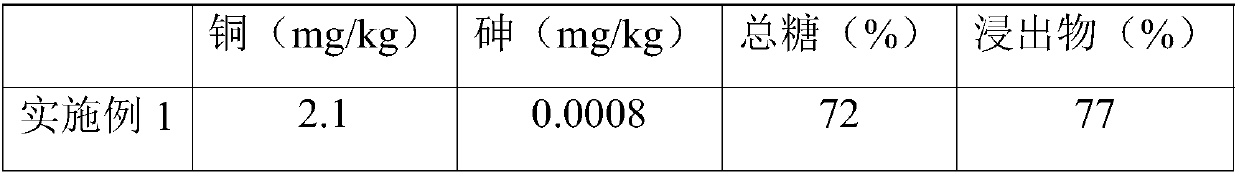

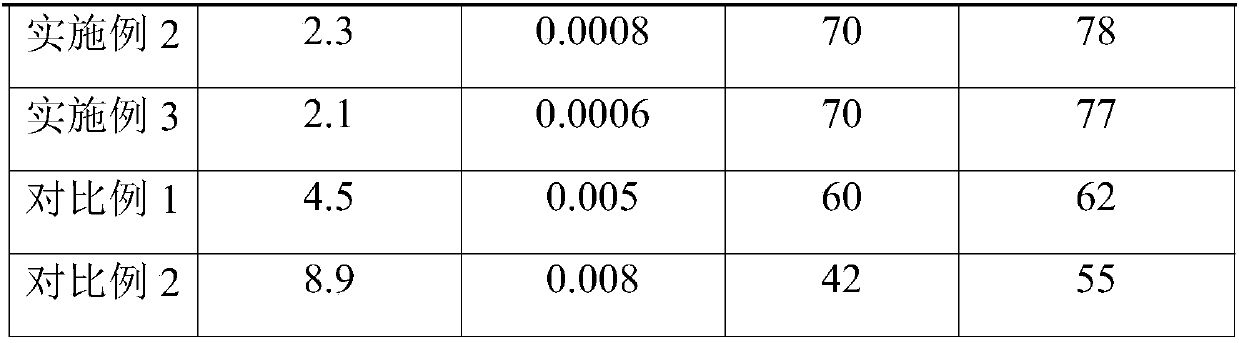

Embodiment 1

[0031] A method for drying and processing Ophiopogon japonicus, comprising the steps of:

[0032] Step 1. Wash the Ophiopogon japonicus

[0033] Put the Ophiopogon japonicus into the mixer, the amount of Ophiopogon japonicus sent is 1 / 2 of the inner cavity volume of the drum mixer; continuously pour water into the mixer, turn on the mixer, and stir for 8 minutes. After confirming that the water outlet of the mixer is clear, close the inlet Water valve; place the receiving cart in advance at the outlet of the mixer, turn on the reverse mode of the mixer, and turn off the mixer after the discharge is completed;

[0034] Step 2, Ophiopogon japonicus pre-drying

[0035] Convey the washed fresh Ophiopogon japonicus to the drum dryer with a conveyor belt, the feeding amount is 1 / 2 of the drum volume, close the feeding port, start the motor of the drying unit, and set the temperature at 55°C-65°C ℃ constant temperature range, and then use the electric heat pump to supply hot air to...

Embodiment 2

[0068] A method for drying Ophiopogon japonicus, comprising the steps of:

[0069] Step 1. Wash the Ophiopogon japonicus

[0070] Put the Ophiopogon japonicus into the mixer, the amount of Ophiopogon japonicus sent is 2 / 3 of the inner cavity volume of the drum mixer; continuously pour water into the mixer, turn on the mixer, and stir for 11 minutes. After confirming that the water outlet of the mixer is clear, close the inlet Water valve; place the receiving cart in advance at the outlet of the mixer, turn on the reverse mode of the mixer, and turn off the mixer after the discharge is completed;

[0071] Step 2, Ophiopogon japonicus pre-drying

[0072] Convey the cleaned fresh Ophiopogon japonicus to the drum dryer with a conveyor belt, the loading amount is 3 / 5 of the drum volume, close the feeding port, start the motor of the drying unit, and set the temperature at 55°C-65°C ℃ constant temperature range, and then use the electric heat pump to supply hot air to dry Ophiopog...

Embodiment 3

[0105] A method for drying Ophiopogon japonicus, comprising the steps of:

[0106] Step 1. Wash the Ophiopogon japonicus

[0107] Put the Ophiopogon japonicus into the mixer, and the amount of Ophiopogon japonicus sent is 3 / 4 of the inner cavity volume of the drum mixer; continuously pour water into the mixer, turn on the mixer, and stir for 12 minutes. After confirming that the water outlet of the mixer is clear, close the inlet Water valve; place the receiving cart in advance at the outlet of the mixer, turn on the reverse mode of the mixer, and turn off the mixer after the discharge is completed;

[0108] Step 2, Ophiopogon japonicus pre-drying

[0109] Convey the washed fresh Ophiopogon japonicus to the drum dryer with a conveyor belt, the loading amount is 2 / 3 of the drum volume, close the feeding port, start the motor of the drying unit, and set the temperature at 55°C-65°C ℃ constant temperature range, and then use the electric heat pump to supply hot air to dry Ophio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com