Salt washer, salt washing equipment and salt making system

A technology of elutriation and salt washing, which is applied in the chemical industry and can solve problems such as the removal of difficult impurities, substandard salt quality, and unsatisfactory needs, and achieve the effect of improving quality and elutriation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

[0033] It should be noted that like numerals and letters denote similar items in the following figures, therefore, once an item is defined in one figure, it does not require further definition and explanation in subsequent figures. Meanwhile, in the description of the present application, the terms "first", "second" and the like are only used to distinguish descriptions, and cannot be understood as indicating or implying relative importance.

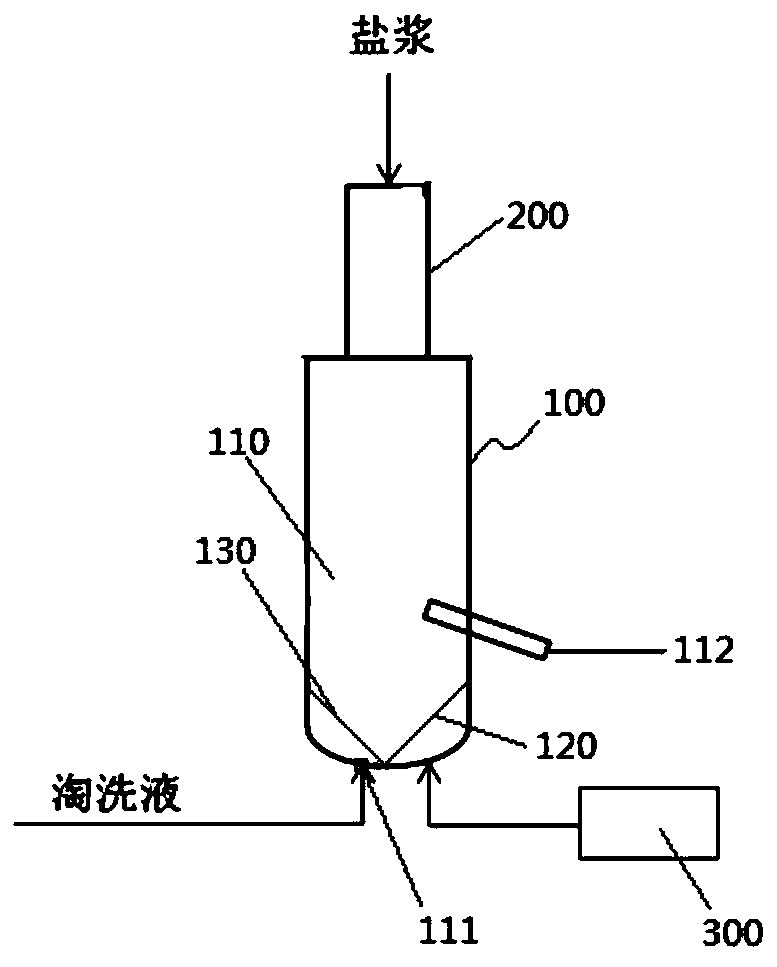

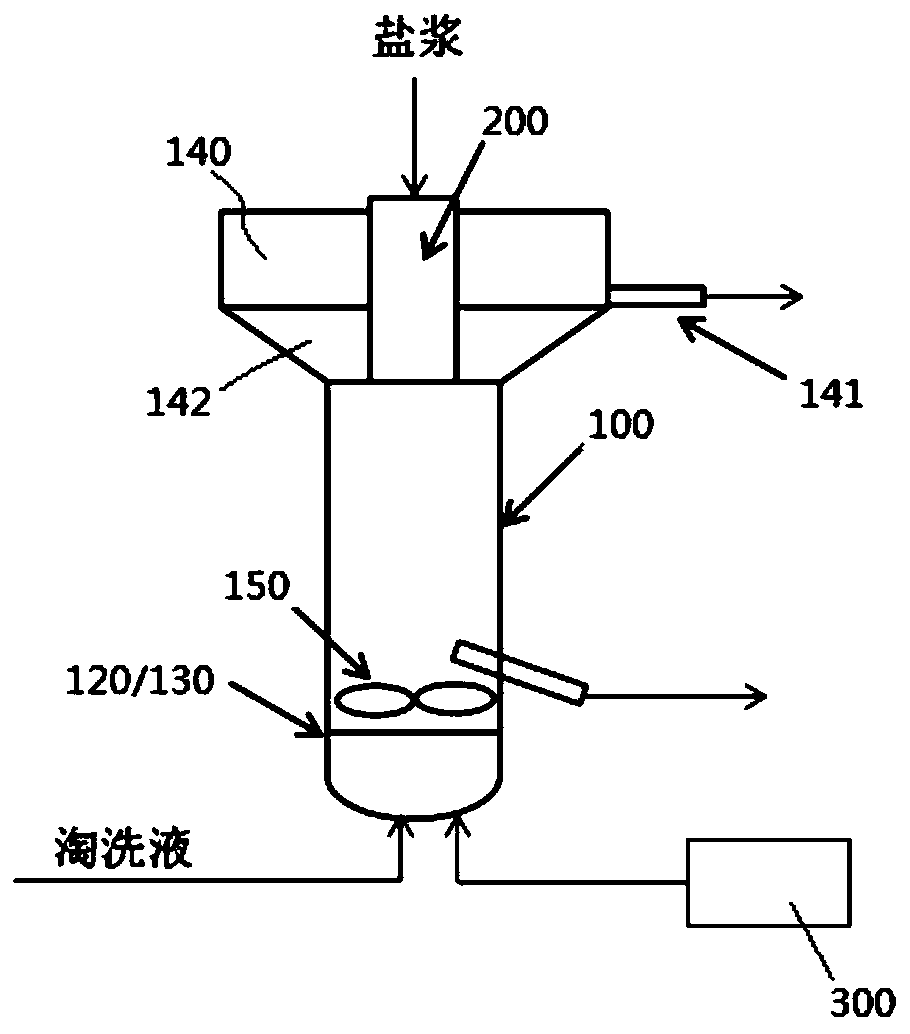

[0034] Please see figure 1 , figure 1 It is a schematic structural diagram of a salt washer provided in the embodiment of this application. The salt scrubber includes an elutriation body 100 , a central pipe 200 and a gas source 300 .

[0035] The elutriation main body 100 includes an elutriation chamber 110 for mixing the brine slurry and the elutriation l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com