A paste-type mercury-free battery slurry and preparation method thereof

A battery and slurry technology, which is applied in the field of paste-type mercury-free battery slurry and its preparation, can solve the problems of mercury-containing industrial wastewater, safety accidents, and environmental pollution, and achieve uniform corrosion inhibition effect, pollution-free electrical performance, Enhance the effect of corrosion inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

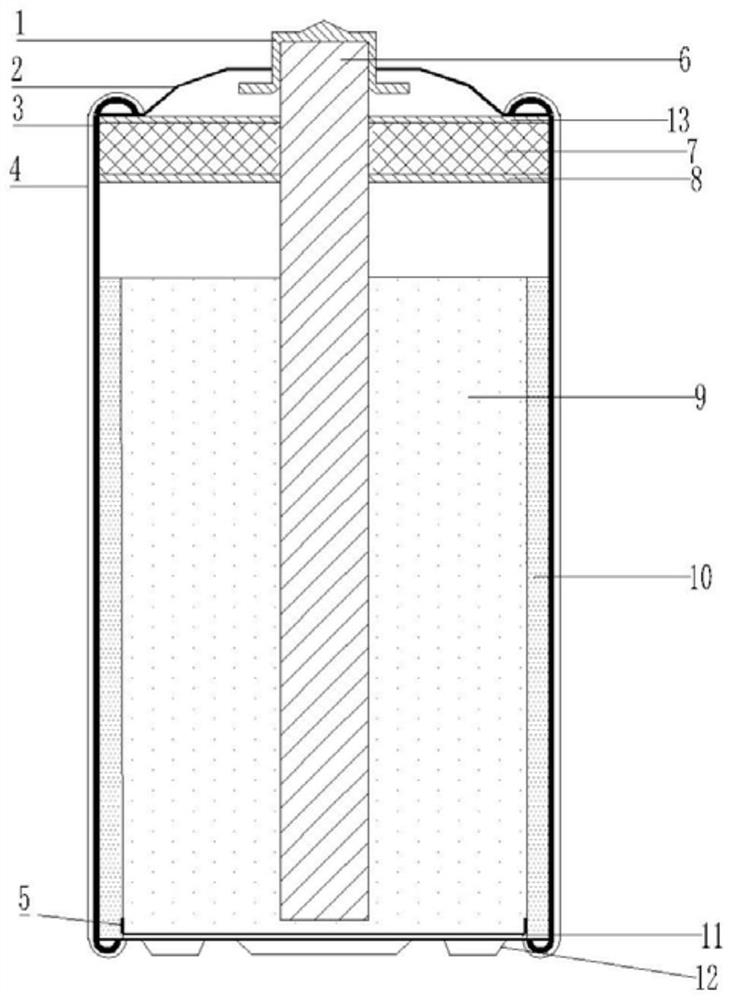

Image

Examples

Embodiment 1

[0033] This embodiment provides a paste-type mercury-free battery slurry, and the raw material components include:

[0034] Electrolyte A 251kg, polyvinyl alcohol solution 7.2kg, paste 104.2kg, alkylphenol polyoxyethylene ether 0.36kg, thickener 109kg, bismuth trichloride 0.035kg, indium chloride 0.018kg, ascorbic acid 0.039kg;

[0035] The electrolyte A is a mixed aqueous solution of 0.64mol / L zinc chloride and 4.39mol / L ammonium chloride; the polyvinyl alcohol solution is 7.9×10 -4 mol / L polyvinyl alcohol and 8×10 -2 A mixed aqueous solution of mol / L boric acid; the paste is a mixture of glutinous rice flour, flour and starch in a weight ratio of 20:29.5:54.7; the thickener is electrolyte B and polyacrylamide in a weight ratio of 99.85: 0.15 composition mixture, the electrolyte B is a mixed aqueous solution of 1.58mol / L zinc chloride and 3.83mol / L ammonium chloride.

[0036] Further, a method for preparing the paste type mercury-free battery slurry is provided, comprising ...

Embodiment 2

[0043] This embodiment provides a paste-type mercury-free battery slurry, and the raw material components include:

[0044] Electrolyte A 240kg, polyvinyl alcohol solution 7kg, paste 100kg, alkylphenol polyoxyethylene ether 0.2kg, thickener 100kg, bismuth trichloride 0.02kg, indium chloride 0.01kg, ascorbic acid 0.02kg;

[0045] The electrolyte A is a mixed aqueous solution of 0.5mol / L zinc chloride and 4mol / L ammonium chloride; the polyvinyl alcohol solution is 7×10 -4 mol / L polyvinyl alcohol and 7×10 -2 The mixed aqueous solution of mol / L boric acid; Described paste is the mixture that glutinous rice flour, flour and starch are formed by weight ratio 15:25:50; Described thickener is electrolyte B and polyacrylamide is 99.8 by weight ratio: 0.2 composition mixture, the electrolyte B is a mixed aqueous solution of 1mol / L zinc chloride and 3mol / L ammonium chloride.

[0046] Further, a method for preparing the paste type mercury-free battery slurry is provided, comprising the ...

Embodiment 3

[0053] This embodiment provides a paste-type mercury-free battery slurry, and the raw material components include:

[0054] Electrolyte A 260kg, polyvinyl alcohol solution 8kg, paste 120kg, alkylphenol polyoxyethylene ether 0.5kg, thickener 120kg, bismuth trichloride 0.04kg, indium chloride 0.02kg, ascorbic acid 0.04kg;

[0055] The electrolyte A is a mixed aqueous solution of 0.7mol / L zinc chloride and 5mol / L ammonium chloride; the polyvinyl alcohol solution is 9×10 -4 mol / L polyvinyl alcohol and 9×10 -2 A mixed aqueous solution of mol / L boric acid; the paste is a mixture of glutinous rice flour, flour and starch in a weight ratio of 25:35:60; the thickener is electrolyte B and polyacrylamide in a weight ratio of 99.9: 0.1 composition mixture, the electrolyte B is a mixed aqueous solution of 2mol / L zinc chloride and 4mol / L ammonium chloride.

[0056] Further, a method for preparing the paste type mercury-free battery slurry is provided, comprising the steps of:

[0057] (1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com