Nickel-cobalt-manganese precursor, preparation method of nickel-cobalt-manganese ternary material and lithium ion battery

A ternary material, nickel-cobalt-manganese technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of difficult to achieve industrialized production, high cost, complicated processes, etc., and achieve easy large-scale industrialization, cycle stability and Improved structural stability and simple and feasible solutions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

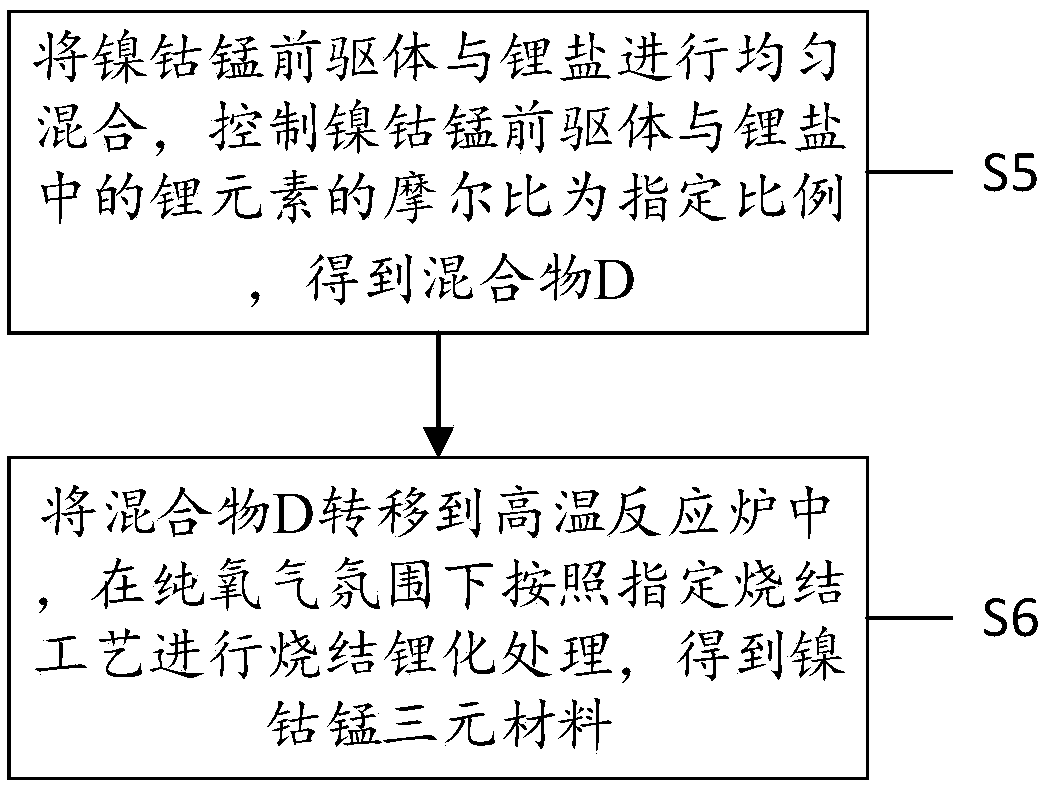

[0028] refer to figure 1 , an embodiment of the present invention proposes a method for preparing a nickel-cobalt-manganese precursor, including:

[0029] S1: Under an inert gas atmosphere, make solution A of nickel salt, cobalt salt, manganese salt and deionized water, and control the total molar concentration of nickel, cobalt and manganese in solution A to the first specified concentration;

[0030] In this embodiment, the reaction was performed under an inert gas range to exclude oxygen in the reaction system and prevent transition metal ions from being oxidized. The first specified concentration includes: the total molar concentration of the three elements of nickel, cobalt and manganese in solution A includes 0.5-5 mol / L. Wherein the nickel salt is one of nickel sulfate, nickel nitrate, nickel chloride or nickel acetate, the cobalt salt is one of cobalt sulfate, cobalt nitrate, cobalt chloride or cobalt acetate, and the manganese salt is manganese sulfate, manganese nit...

Embodiment 1

[0046] 1. Preparation of nickel-cobalt-manganese precursor (NCM811 hydroxide precursor) material containing polystyrene particles (PSB): under nitrogen protection, nickel sulfate, cobalt sulfate, and manganese sulfate were mixed in a molar ratio of 8:1:1 Be made into the mixed solution of 2.5molL-1, then add the polystyrene particle (PSB) that the diameter of 1% is about 400nm in mass ratio, then add the hexadecyltrimethylammonium bromide that accounts for total mass fraction 1% as Dispersant, fully stirred and mixed evenly to obtain solution A; sodium hydroxide was formulated into 4molL-1 alkali solution as a precipitant, and 1mol / L ammonia water was used as a complexing agent, and these three solutions were added dropwise to In a continuously stirred reactor, the pH value of the reaction (pH=9.5) and the temperature of the reaction (40°C) are strictly controlled. The reaction time is 8 hours, and the aging time after the reaction is 12 hours. Washing and drying at a constant...

Embodiment 2

[0049] 1. Preparation of PSB-containing nickel-cobalt-manganese precursor (NCM622 hydroxide precursor) material: under the protection of nitrogen, nickel nitrate, cobalt nitrate, and manganese nitrate were prepared in a molar ratio of 6:2:2 to 0.5molL-1 Mix the solution, then add polystyrene particles (PSB) with a diameter of about 50nm with a mass ratio of 0.1%, and then add 0.01% of the total mass fraction of hexadecyltrimethylammonium bromide as a dispersant, fully stir and mix evenly , to obtain solution A; the 0.5molL-1 alkali solution prepared by sodium hydroxide is used as a precipitating agent, and 0.1mol / L ammonia water is used as a complexing agent, and these three solutions are added dropwise to the continuous stirring reaction in parallel. In the kettle, and strictly control the pH value of the reaction (pH=8) and the temperature of the reaction (60°C), the reaction time is 6h, and the aging time after the reaction is 10h, the coprecipitation solution is suction fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com