A slurry and oxygen feed control method for a multi-channel nozzle

A multi-channel, slurry technology, applied in the direction of granular/powdered fuel gasification, gasification process, and production of combustible gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

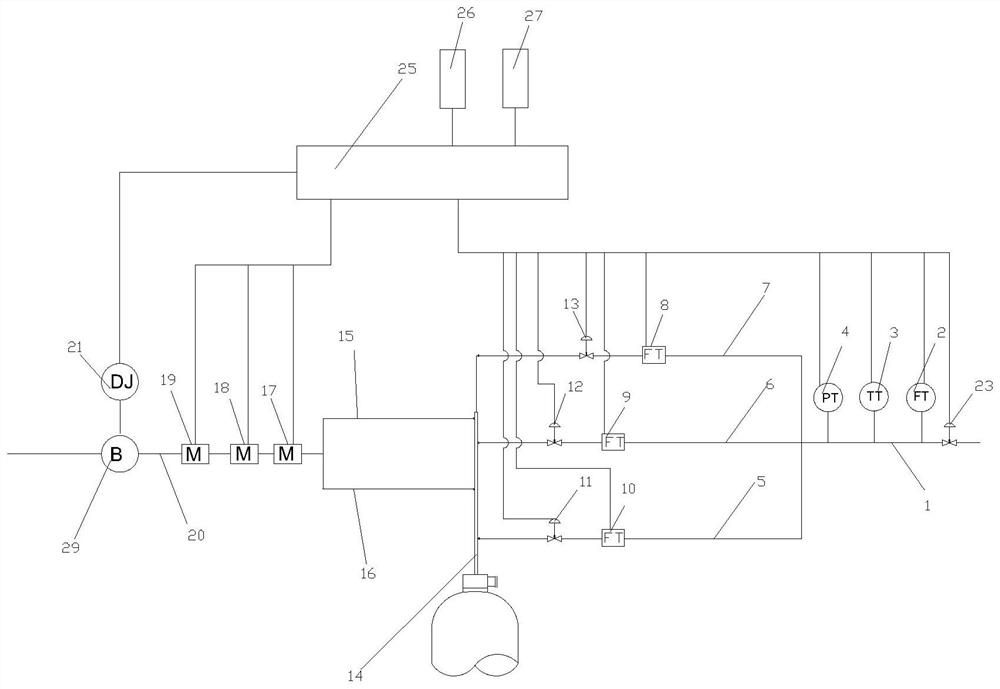

[0080] Such as figure 1 and image 3 Shown, a kind of slurry and oxygen feed control method of multi-channel nozzle, the device that this method adopts comprises multi-channel nozzle and control module, and described multi-channel nozzle comprises nozzle 14, the slurry conveying that is arranged on nozzle 14 mechanism and an oxygen delivery mechanism, the slurry delivery mechanism includes a slurry channel, a slurry flow detection module and a slurry delivery adjustment mechanism, and the slurry channel includes a central oxygen slurry channel 15 and an epoxy slurry channel 16, so The oxygen delivery mechanism includes a central oxygen channel 7 connected to the main oxygen channel 1, an oxygen channel 6 of the middle ring pipe and an oxygen channel 5 of the outer ring pipe, and the control module includes a controller 25 and an A display screen 26 and an alarm 27, the central oxygen channel 7 is provided with a first regulating valve 13 and a first oxygen partial flow detectio...

Embodiment 2

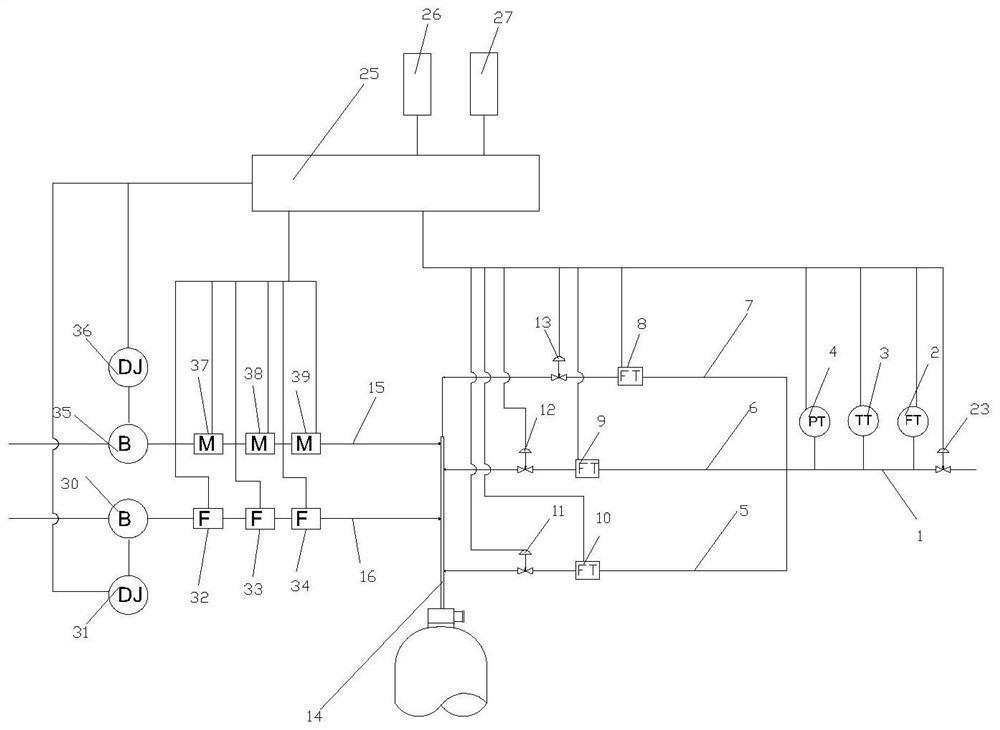

[0124] In this embodiment, the difference from embodiment 1 is:

[0125] Such as figure 2 As shown, in this embodiment, the slurry flow detection module includes a first slurry sub-flow detection unit 37, a second slurry sub-flow detection unit 38 and a third slurry sub-flow detection unit 38 arranged on the central oxygen slurry channel 15. The sub-flow detection unit 39 and the fourth slurry sub-flow detection unit 32, the fifth slurry sub-flow detection unit 33 and the sixth slurry sub-flow detection unit 34 arranged on the epoxy slurry channel 16;

[0126] The slurry conveying adjustment mechanism includes a first high-pressure slurry pump 35 arranged on the central oxygen slurry channel 15, a first motor 36 driving the first high-pressure slurry pump 35, and a first motor 36 arranged on the epoxy slurry channel 16. The second high-pressure slurry pump 30 and the second motor 31 driving the second high-pressure slurry pump 30, the first slurry sub-flow detection unit 37,...

Embodiment 3

[0150] In this embodiment, the difference from embodiment 2 is:

[0151] In this embodiment, it is further preferred that the ratio of the total volume flow rate of oxygen to the total volume flow rate of the slurry is 471.

[0152] In this embodiment, the slurry in the central oxygen slurry channel 15 is coal slurry, and the density of the coal slurry is 1220kg / m 3 ; The slurry in the epoxy slurry channel 16 is coal slurry, and the density of the coal slurry is 1220kg / m 3 ;

[0153] In this embodiment, it is further preferred that the set value of the partial flow of oxygen in the central oxygen channel 7 is 8% of the set value of the total volume flow of oxygen, and the set value of the partial flow of oxygen in the oxygen channel 6 of the central ring pipe is set at the set value of the total volume flow of oxygen. 40% of the fixed value and the set value of the oxygen partial flow of the outer ring pipe oxygen channel 5 is 52% of the set value of the total volume flow of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com