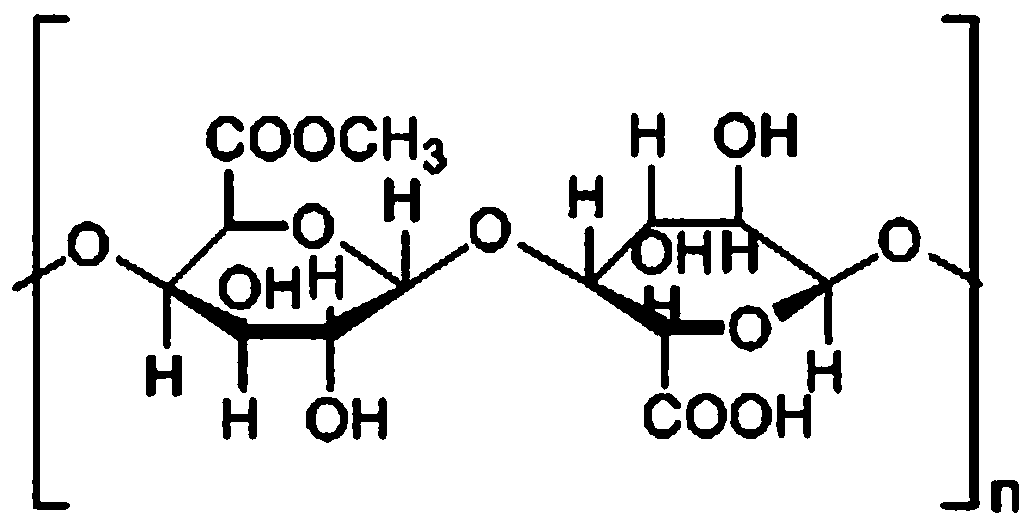

Method for extracting pectin from green sunflower plates by salt

A technology of sunflower green and sunflower, applied in the field of pectin extraction technology, can solve the problems of heavy processing workload, affecting the performance of pectin, increasing the size, etc., and achieve the effect of high raw material utilization rate, low solid-liquid ratio, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

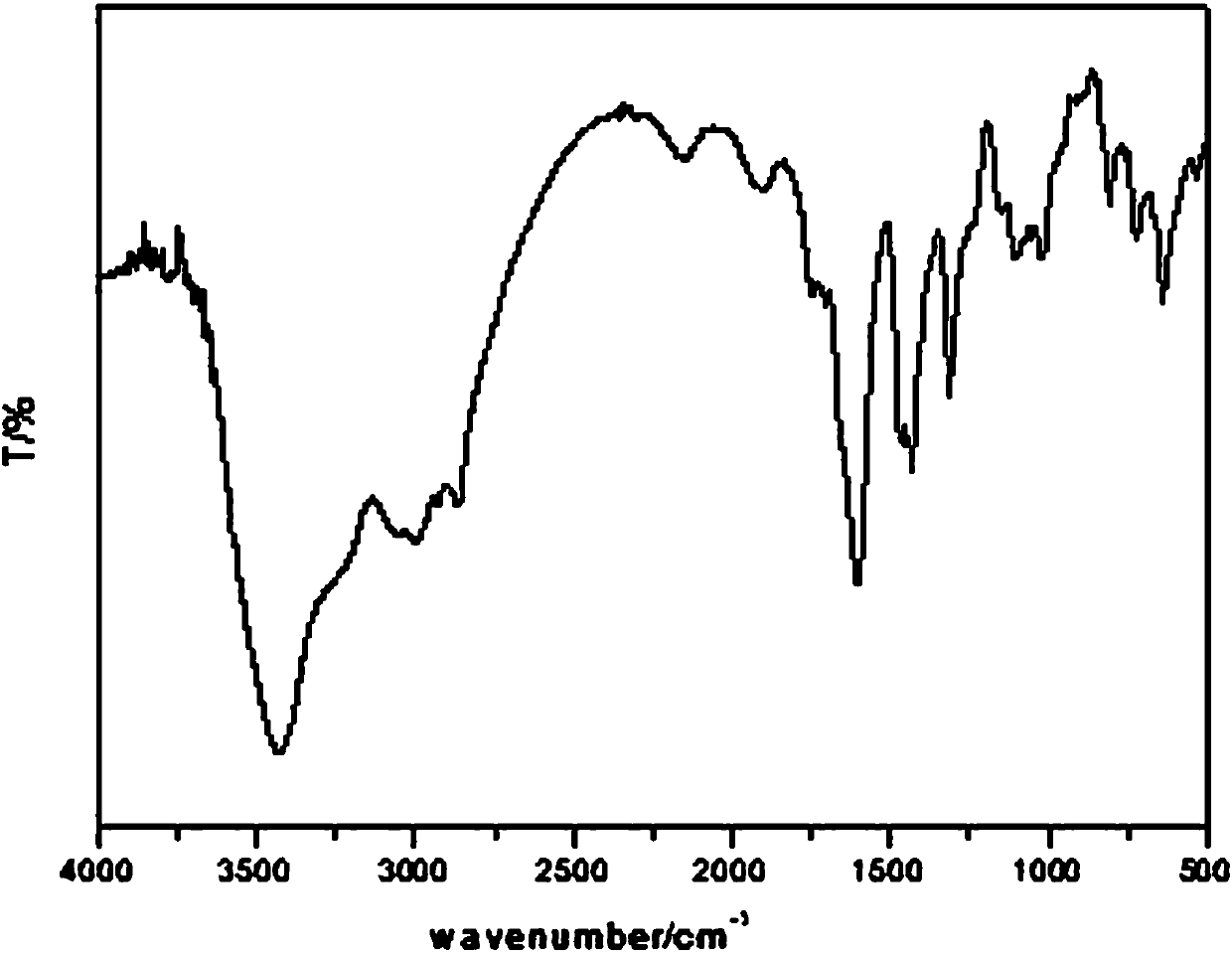

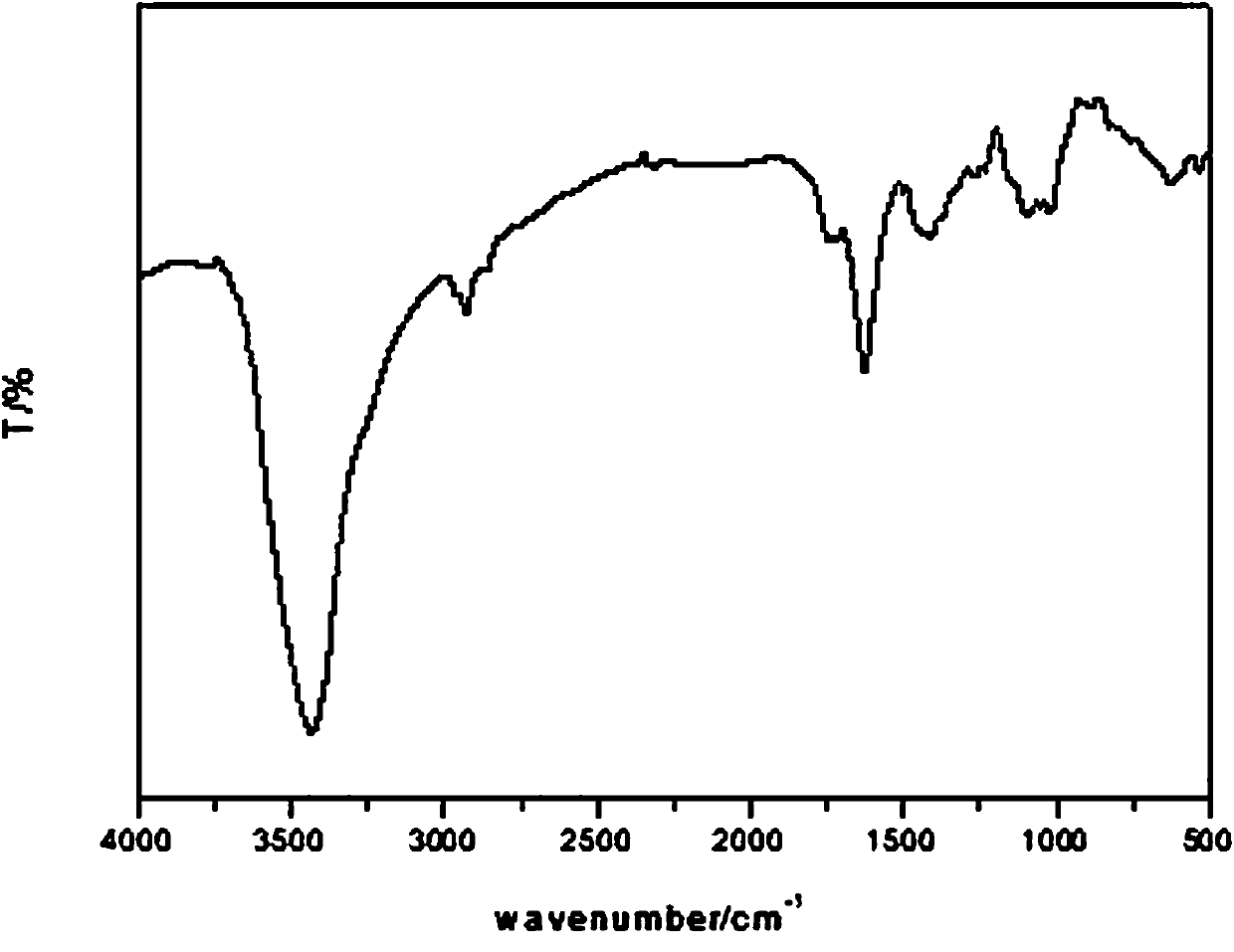

Method used

Image

Examples

Embodiment 1

[0022] Example 1: A method for extracting pectin from sunflower green plate using salt, including the following steps:

[0023] Step (1): Select a fresh sunflower plate that has been de-seeded, rinse it several times with clean water to remove sand and dust, and drain it. The water content of the fresh sunflower plate is 80-90%;

[0024] Step (2): Cut the green plate into pieces with a diameter of 0.8cm;

[0025] Step (3): Put the lumpy sunflower green plate into a constant temperature water bath to inactivate the enzyme at a temperature above 95°C for 15 minutes, filter with a 150-mesh nylon cloth, and use the filter cake for later use;

[0026] Step (4): Use the filter cake obtained in step (3) as the extraction raw material, add distilled water at a material-to-liquid ratio of 1:15, add 0.3% ammonium oxalate to extract the raw material for pectin, and extract at 80°C for 60 minutes;

[0027] Step (5): filtering, separating the residue and collecting the filtrate;

[0028] Step (6): Th...

Embodiment 2

[0030] Example 2: A method for extracting pectin from sunflower green plates using salt, including the following steps: the green plates are cut into 1.0cm pieces; the block-shaped sunflower green plates are placed in a constant temperature water bath above 95°C to inactivate the enzyme for 18 minutes, Filter with 200 mesh nylon cloth, and filter cake for use; filter cake is used as the raw material for extraction, add distilled water according to the material-to-liquid ratio of 1:5, add 0.2% ammonium oxalate to extract the raw material for pectin, and extract for 45 minutes at 85°C; filter, The filtrate was subjected to rotary distillation under reduced pressure at 60°C and concentrated to 0.3 times the volume of the original solution to obtain a concentrated sunflower disk extract; ethanol precipitation was carried out with ethanol with a concentration of 90%-95% and an amount of 1.2-1.6 times the volume of the concentrated solution. The sequence of alcohol precipitation is to...

Embodiment 3

[0031] Example 3: A method for extracting pectin from sunflower green plate using salt, including the following steps: the green plate is cut into 1.5 cm pieces; the block-shaped sunflower green plate is placed in a constant temperature water bath above 95°C to inactivate the enzyme for 22 minutes, Filter with 300 mesh nylon cloth, and filter cake for use; filter cake as the raw material for extraction, add distilled water according to the material-to-liquid ratio of 1:10, add sodium citrate with a concentration of 0.8% to extract pectin, and extract at 90°C for 20 minutes; filter; , The filtrate was subjected to vacuum rotary distillation at 65°C and concentrated to 0.4 times the volume of the original solution to obtain a concentrated sunflower disk extract; use ethanol with a concentration of 90%-95% and an amount of 2 times the volume of the concentrated solution for alcohol precipitation. The precipitation sequence is that the extract is introduced into ethanol, and the alc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com