Production technology of high-purity teicoplanin

A technology for the production of teicoplanin, which is applied in the field of high-purity teicoplanin production technology, can solve the problems of many by-products and low production efficiency, and achieve the reduction of by-products, increase of yield, and increase of output Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

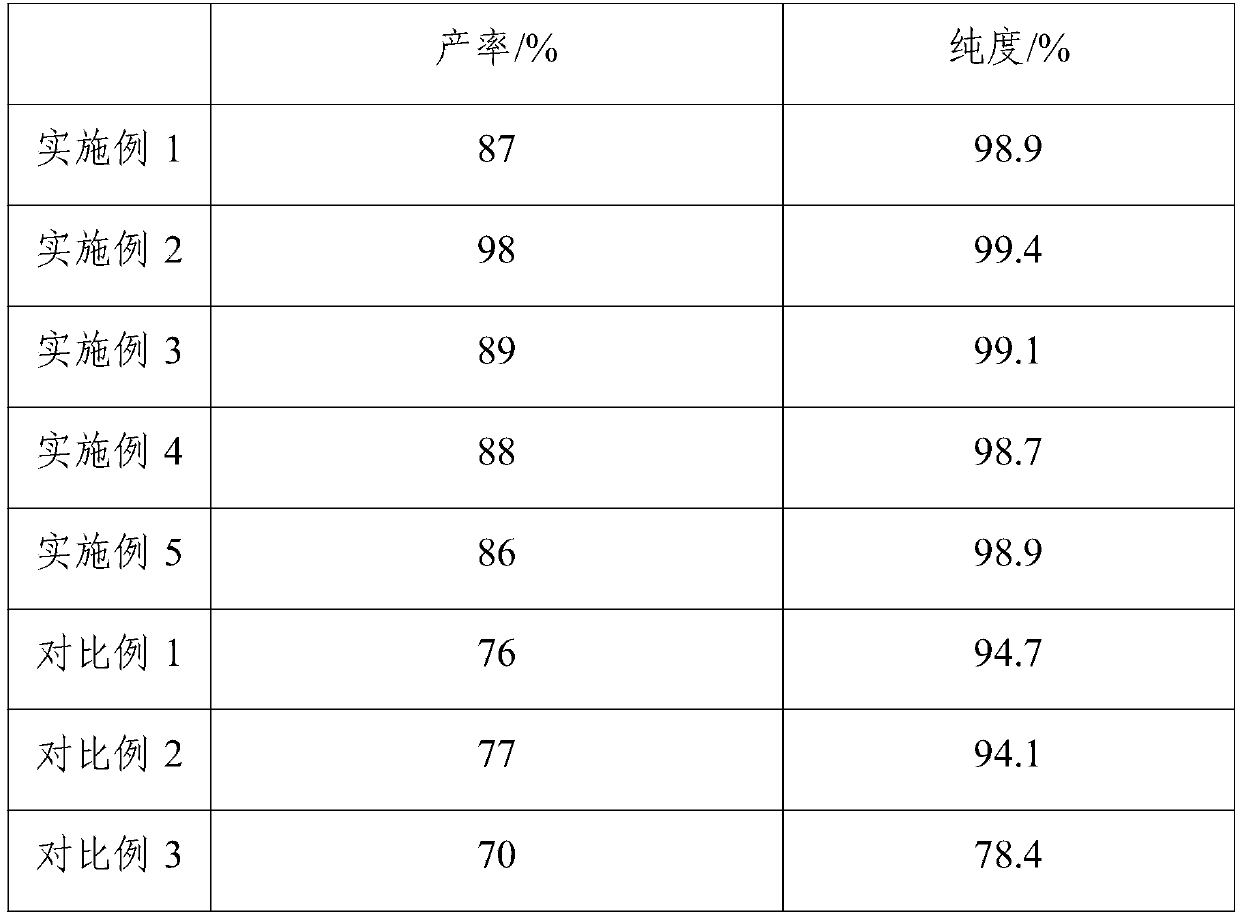

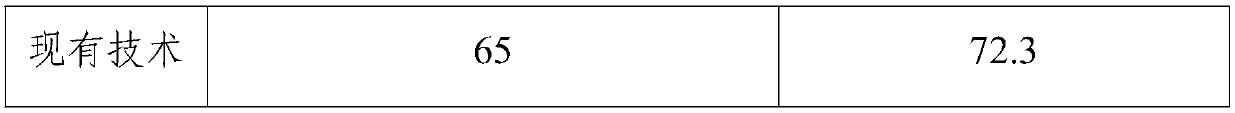

Examples

Embodiment 1

[0028] A kind of production technology of high-purity teicoplanin, comprises the steps:

[0029] 1) preparing slant medium, seed medium and fermentation medium;

[0030] Wherein, the preparation method of the slant medium is: according to weight parts, take 5 parts of soluble starch, 1.5 parts of yeast extract, 1 part of glucose, 4 parts of agar powder, 0.1 part of calcium carbonate, 1 part of acetic acid, [Mg 2 (OH) 4 ]·mH 2 O·mH 2 O 2 parts of prepared slant medium, adjust the pH to be 7.0;

[0031] Wherein, the preparation method of the seed medium is as follows: according to parts by weight, take 7 parts of soluble starch, 5 parts of mannitol, 3 parts of yeast powder, and 5 parts of peptone to prepare the seed medium, and adjust the pH to 7.2;

[0032] Wherein, the preparation method of the fermentation medium is as follows: according to parts by weight, 3 parts of dextrin, 10 parts of soluble starch, 5 parts of soybean powder, 6 parts of corn steep liquor, and 0.5 par...

Embodiment 2

[0038] A kind of production technology of high-purity teicoplanin, comprises the steps:

[0039] 1) preparing slant medium, seed medium and fermentation medium;

[0040] Wherein, the preparation method of the slant medium is: according to parts by weight, take 8 parts of soluble starch, 0.5 parts of yeast extract, 3 parts of glucose, 2 parts of agar powder, 0.5 parts of calcium carbonate, 0.2 parts of acetic acid, [MgFe(OH) 4 ][SO 4 ] 0.5 mH 2 04 parts of preparation slant culture medium, adjust pH to be 6.8;

[0041] Wherein, the preparation method of the seed culture medium is: according to weight parts, take 10 parts of soluble starch, 3 parts of mannitol, 6 parts of yeast powder, and 2 parts of peptone to prepare the seed culture medium, and adjust the pH to 7.4;

[0042] Wherein, the preparation method of the fermentation medium is: according to the parts by weight, take 1 part of dextrin, 15 parts of soluble starch, 2 parts of soybean powder, 10 parts of corn steep l...

Embodiment 3

[0048] A kind of production technology of high-purity teicoplanin, comprises the steps:

[0049] 1) preparing slant medium, seed medium and fermentation medium;

[0050] Wherein, the preparation method of the slant medium is: according to the parts by weight, take 5 parts of soluble starch, 0.5 parts of yeast extract, 3 parts of glucose, 4 parts of agar powder, 0.1 part of calcium carbonate, 0.2 part of acetic acid, [Fe 2 (OH) 4 ][SO 4 ]·mH 2 0. 4 parts of preparation slant culture medium, adjust pH to be 7.0;

[0051] Wherein, the preparation method of the seed medium is as follows: according to parts by weight, take 7 parts of soluble starch, 3 parts of mannitol, 6 parts of yeast powder, and 5 parts of peptone to prepare the seed medium, and adjust the pH to 7.2;

[0052] Wherein, the preparation method of the fermentation medium is: according to the parts by weight, take 1 part of dextrin, 15 parts of soluble starch, 5 parts of soybean powder, 6 parts of corn steep liqu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com