Flexible temperature-resistant printing magnetic membrane material and preparation method thereof

A technology of magnetic film and sheet materials, applied in the direction of copying/marking methods, printing, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

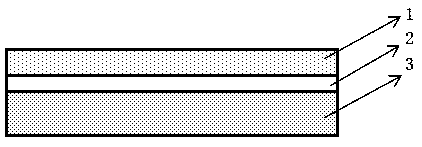

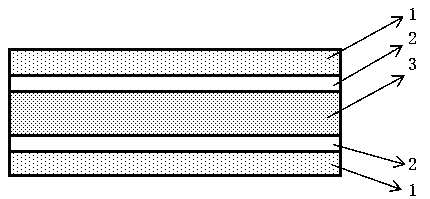

[0034] like figure 1 As shown, a flexible temperature-resistant printable magnetic film material is composed of closely connected printable PVC film layers, PET film layers, and magnetic layers; the PET film layer is transparent and has a thickness of 0.01mm; the The magnetic layer, the adhesive is CPE, and the sheet-shaped permanent magnet anisotropic ferrite magnetic powder is a modified high molecular polymer layer; the printable PVC film layer and the PET film layer are tightly connected by curing glue ; The PET film layer and the magnetic layer are closely connected by curing glue; the thickness of the printable PVC film layer is 0.08mm, and the thickness of the magnetic layer is 0.30mm. The flexible temperature-resistant printable magnetic film material The total thickness is 0.39mm.

[0035] The preparation method of the flexible temperature-resistant printable magnetic diaphragm material comprises the following steps:

[0036] 1. Fabrication of the magnetic layer:

...

Embodiment 2

[0045] like figure 1As shown, a flexible temperature-resistant printable magnetic film material is composed of closely connected printable PVC film layers, PET film layers, and magnetic layers; the PET film layer is transparent and has a thickness of 0.04mm; the The magnetic layer, the adhesive is CPE, the modified high molecular polymer layer of the sheet-shaped permanent magnet anisotropic ferrite magnetic powder and the sheet-shaped soft magnetic silicon-alumina powder as filler; the printable PVC film layer and the PET film layer The way of close connection is curing glue bonding; the close connection method of PET film layer and magnetic layer is bonding with curing glue; the thickness of PVC film layer is 0.08mm, the thickness of the magnetic layer is 0.6mm, and the flexible and durable The total thickness of the temperature-printable magnetic diaphragm material is 0.72mm.

[0046] The preparation method of the flexible temperature-resistant printable magnetic diaphragm...

Embodiment 3

[0063] like figure 1 As shown, a flexible temperature-resistant printable magnetic film material is composed of closely connected printable PVC film layers, PET film layers, and magnetic layers; the PET film layer is transparent and has a thickness of 0.005mm; the For the magnetic layer, the adhesive is CPE, and the flake sendust soft magnetic is a modified high molecular polymer layer as a filler; the way of tightly connecting the printable PVC film layer and the PET film layer is bonding of cured glue; The tight connection mode curing glue of PET film layer and magnetic layer is pasted; The thickness of PVC film layer is 0.08mm, and the thickness of described magnetic layer is 0.30mm, and the total thickness of described flexible temperature-resistant printable magnetic film material is 0.08mm. 0.385mm.

[0064] The preparation method of the flexible temperature-resistant printable magnetic diaphragm material comprises the following steps:

[0065] 1. Production of the mag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com