Double-axis 3D printing device of cement handicraft

A technology for 3D printing and handicrafts, applied in the field of dual-axis 3D printing devices for cement handicrafts, which can solve the problems of fragility, cross-section, surface accuracy and mechanical properties, and achieve quality improvement, height assurance, accurate 3D positioning and printing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

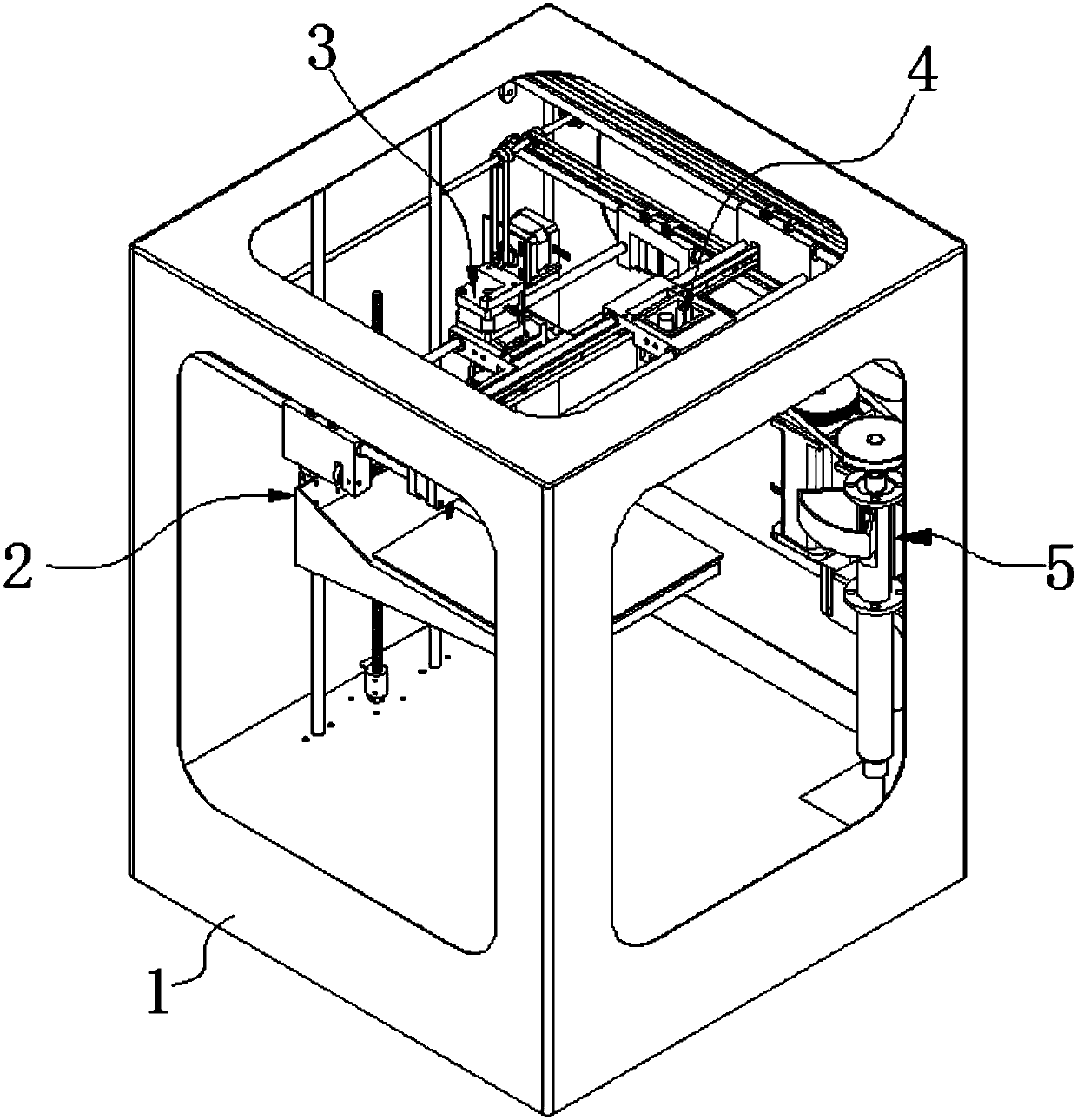

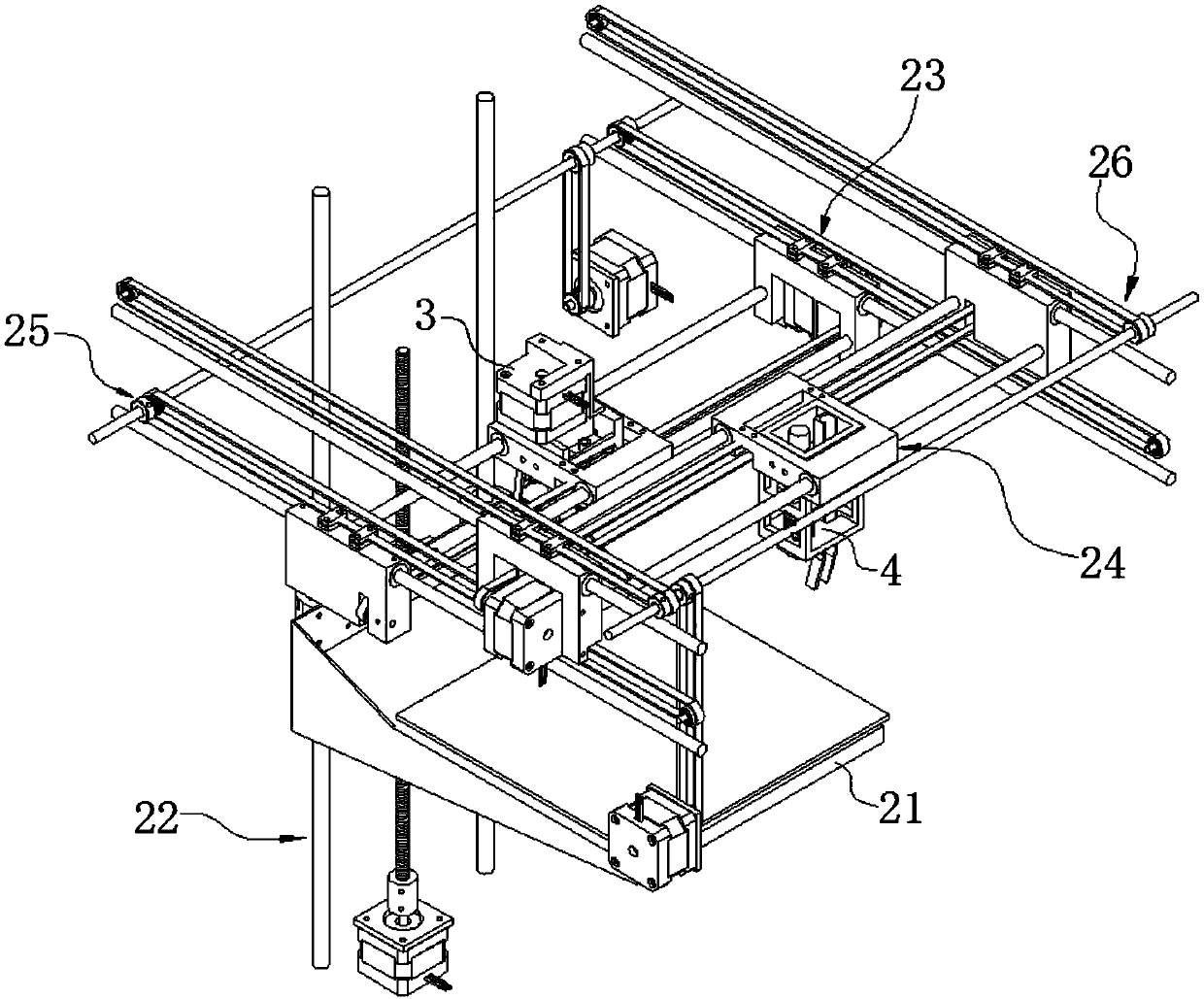

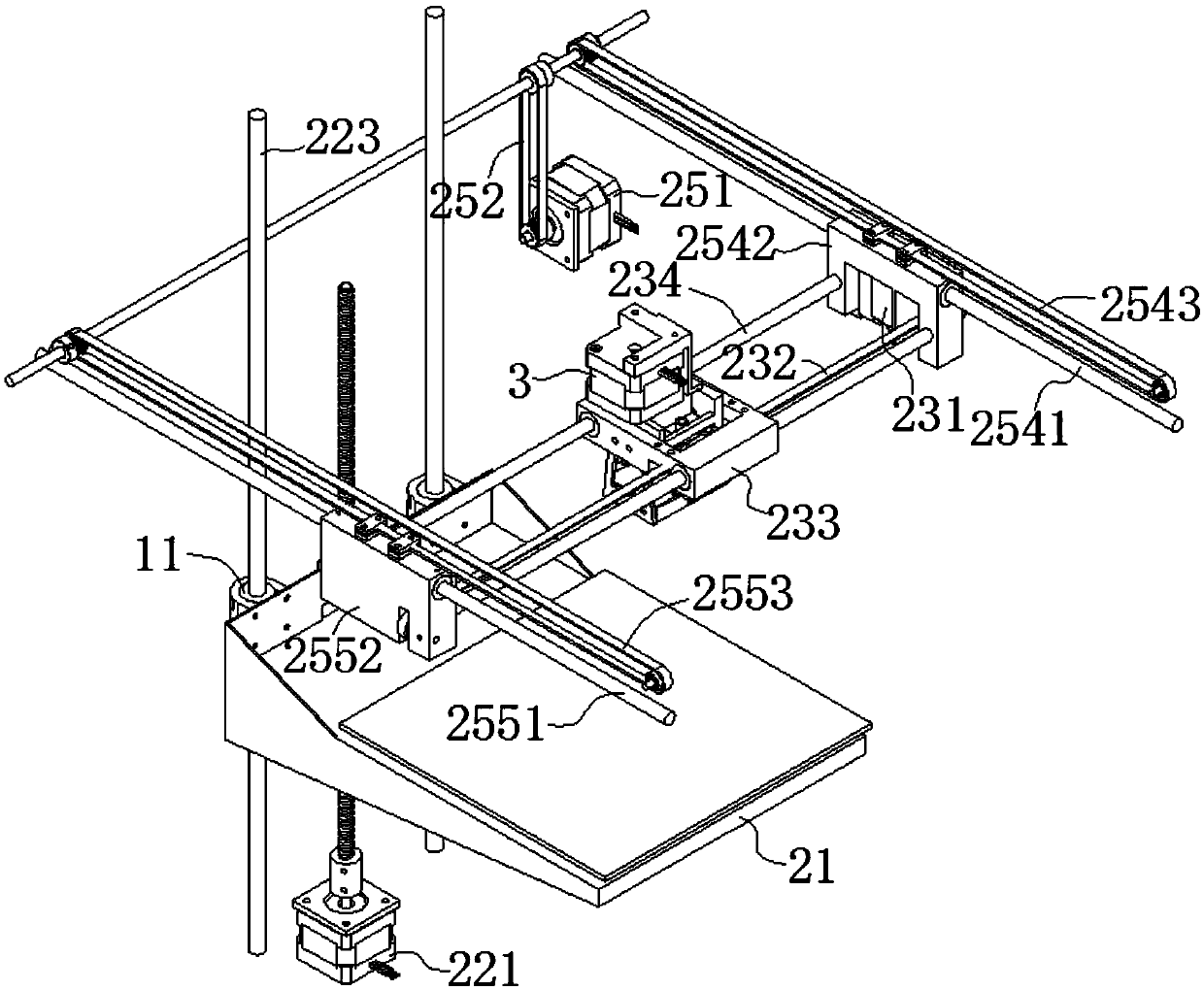

[0028] See attached Figures 1 to 5 , a dual-axis 3D printing device for cement handicrafts, which includes a machine base 1, a multi-axis motion mechanism 2 arranged on the machine base 1, a TPU fiber dual nozzle assembly 3 and a cement nozzle assembly 4 driven by the multi-axis motion mechanism 2, And the extruding mechanism 5 that feeds the cement nozzle assembly 4; the multi-axis motion mechanism 2 includes the bottom bed 21, the Z axis assembly 22, the XI axis assembly 23, the XII axis assembly 24, the YI axis assembly 25 and the YII axis assembly 26 , the Z-axis assembly 22, the XI-axis assembly 23, and the YI-axis assembly 25 form a three-dimensional space coordinate system corresponding to the TPU fiber double nozzle assembly 3, and the Z-axis assembly 22, the XII-axis assembly 24, and the YII-axis assembly 26 form a corresponding cement The three-dim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com