A tig welding method for improving welding penetration and preventing back oxidation

A back and penetration technology, applied in the direction of welding equipment, welding medium, welding equipment, etc., can solve the problems of low welding efficiency, back oxidation, insufficient penetration, etc., to improve welding efficiency, prevent back oxidation, and form a good back Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

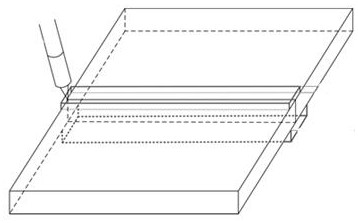

Method used

Image

Examples

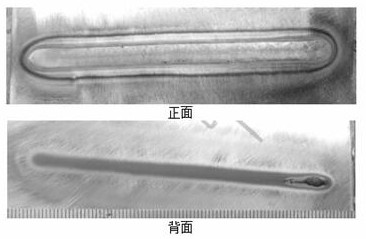

Embodiment 1

[0030] Weigh the powder according to the following mass percentages: SiO2 22%, CaF2 5%, TiO2 28%, MnO2 5%, Mn 22%, Si18%. After mixing the powder evenly, mix it with the binder at a ratio of 1:4 to 6 to form a protective agent, then dilute the protective agent with acetone at a ratio of 1.5 to 3:1, and coat the front with a thickness of 0.1mm and the back with a thickness of 2mm, put it in the air for 5-10 minutes, and then weld.

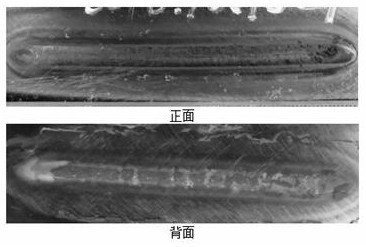

Embodiment 2

[0032] Weigh the powder according to the following mass percentages: SiO2 22%, CaF2 5%, TiO2 25%, MnO2 4%, Mn 26%, Si18%. After mixing the powder evenly, mix it with the binder at a ratio of 1:4 to 6 to form a protective agent, then dilute the protective agent with acetone at a ratio of 1.5 to 3:1, and coat the front with a thickness of 0.1mm and the back with a thickness of 2mm, put it in the air for 5-10 minutes, and then weld.

Embodiment 3

[0034] Weigh the powder according to the following mass percentages: SiO2 22%, CaF2 5%, TiO2 25%, MnO2 4%, Mn 24%, Si20%. After mixing the powder evenly, mix it with the binder at a ratio of 1:4 to 6 to form a protective agent, then dilute the protective agent with acetone at a ratio of 1.5 to 3:1, and coat the front with a thickness of 0.1mm and the back with a thickness of 2mm, put it in the air for 5-10 minutes, and then weld.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com