Electric welding machine with charging output connector

A technology of output interface and electric welding machine, applied in arc welding equipment, battery circuit devices, current collectors, etc., can solve the problems of circuit incompatibility, machine volume increase, etc., and achieve the effect of electric welding and charging functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

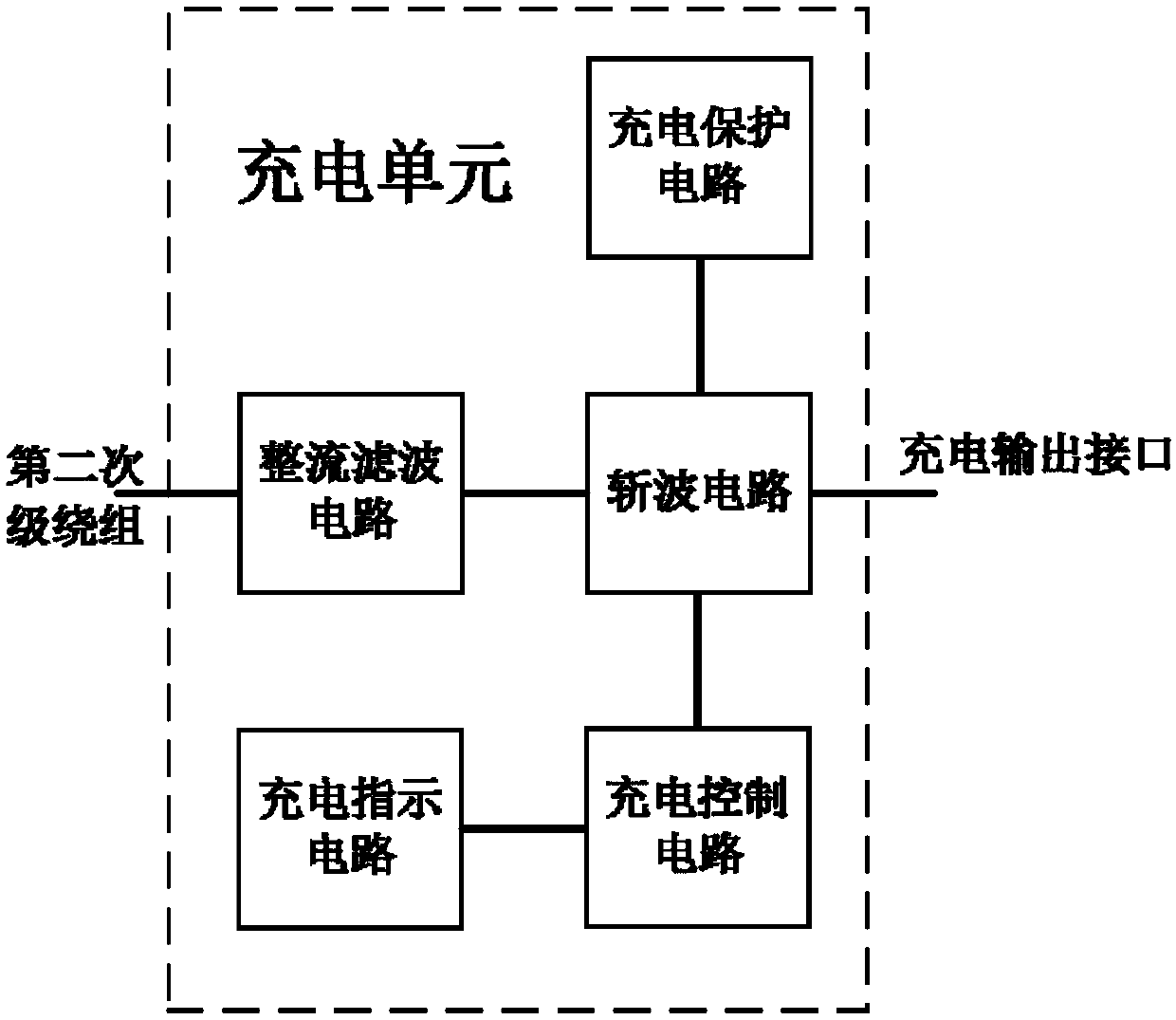

[0027] The technical solutions provided by the present invention will be further described below in conjunction with the accompanying drawings.

[0028] The purpose of the present invention is to integrate the charger function on the basis of the existing electric welding machine circuit. The specific inventive idea is to connect the main transformer of the inverter electric welding machine through the secondary winding (without changing any electric welding machine circuit), so that the machine can realize the welding function. It also has a DC charging function. The input power of the charging circuit uses a high-temperature electronic wire to wrap a certain number of windings on the main transformer of the welding machine, and the high-frequency AC power obtained is rectified by a Schottky diode for full-bridge rectification, and then filtered by an electrolytic capacitor to obtain a stable DC power supply, and then Use PWM control chip, field effect tube and DC inductor to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com