Workpiece clamp for inner-meshing forced movement chain roller mill

A technology of forced movement and workpiece fixtures, which is applied in the direction of manufacturing tools, gear cutting machines, mechanical equipment, etc., can solve the problems that the accuracy cannot be improved, and achieve the effect of high processing accuracy and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

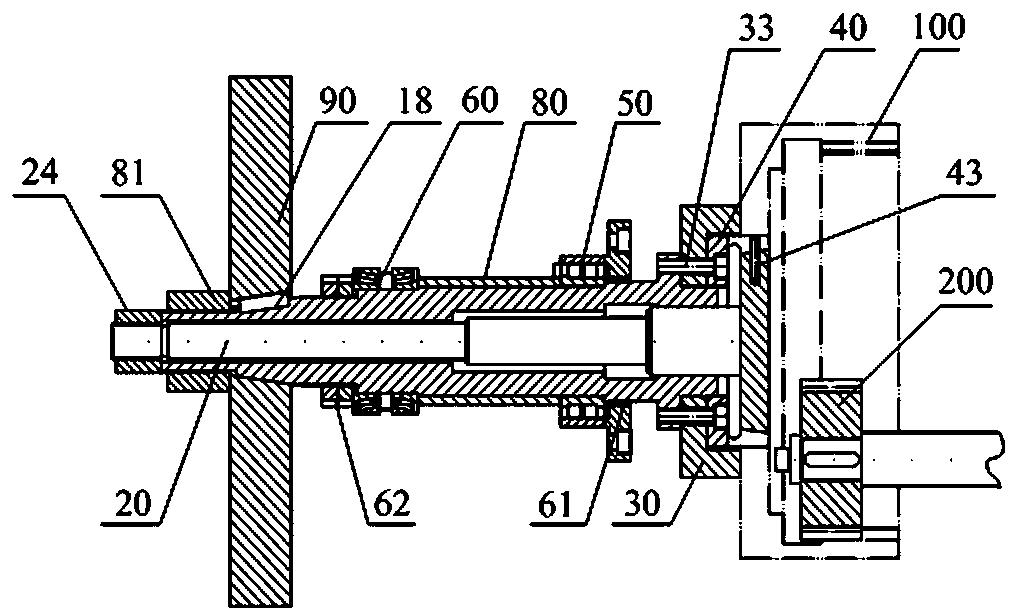

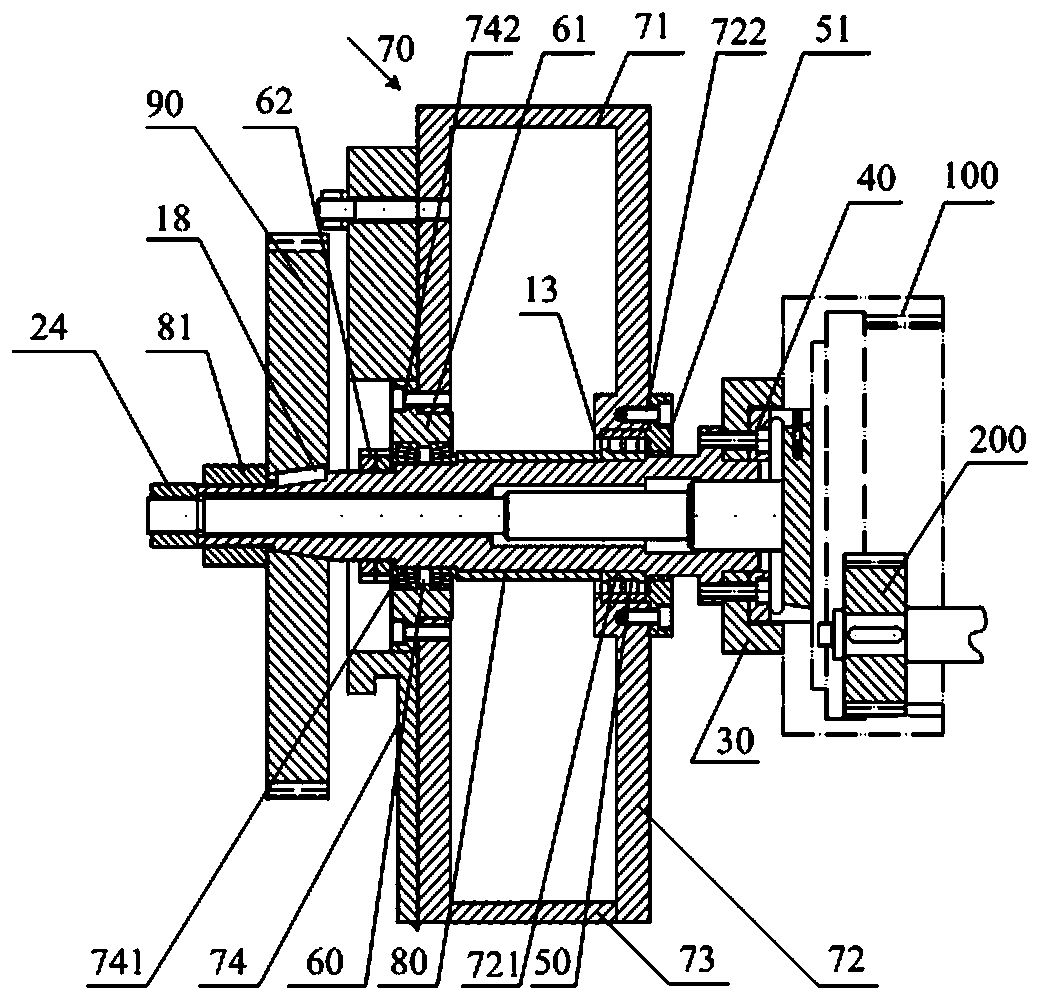

[0023] Such as figure 1 As shown, the first embodiment of the present invention proposes a workpiece fixture for an internal meshing forced kinematic chain roller mill, which is used to install the processed ring gear 100 and drive the installed processed ring gear 100, and the internal meshing forced movement The workpiece fixture of the chain roller mill includes a main shaft 10 for receiving and transmitting torque, a tie rod 20 set in the central through hole 11 of the main shaft 10 for installing the inner ring gear 100 to be processed, and a pull rod 20 sleeved on the main shaft 10 for axial The clamp base 30 of the processed ring gear 100 installed with the positioning rod 20 and the elastic sleeve 40 sleeved on the main shaft 10 are used for radially tightening the processed ring gear.

[0024] The internal m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com