Casting post-finishing assembly line and finishing method adopting same

A casting finishing and assembly line technology, applied in foundries, casting equipment, safety devices, etc., can solve the problems of difficult manual finishing, many labor, poor generality of the assembly line, etc., to improve the quality of the working environment, reduce the error rate, Realize the effect of online automatic finishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

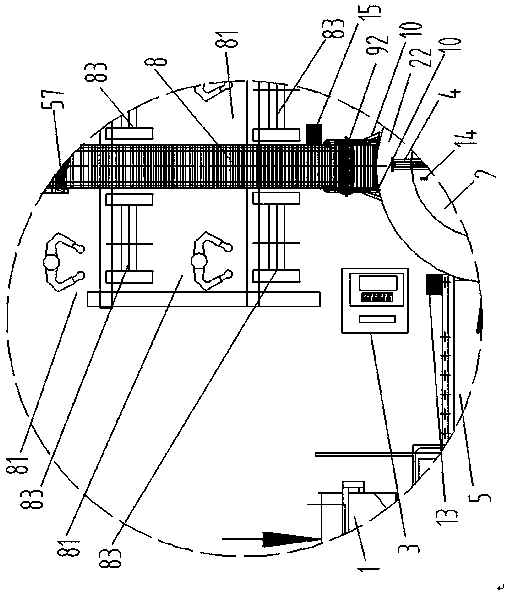

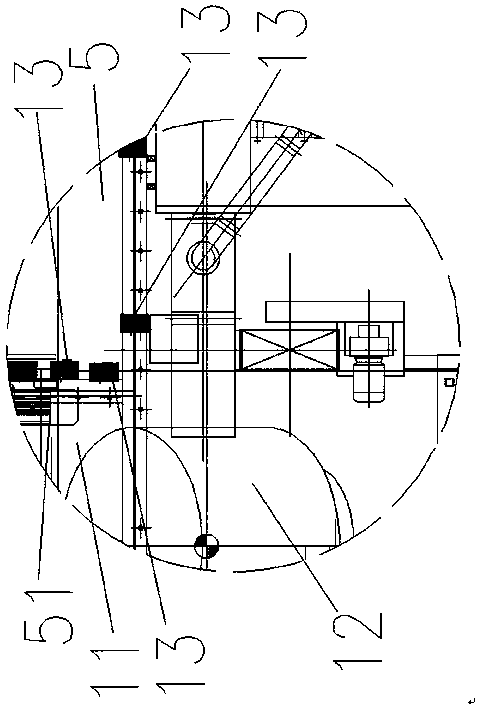

[0044] Example 1. Such as Figure 1-6 As shown, the finishing line after casting is characterized in that it includes a feeding mechanism 1, a finishing mechanism, a conveying mechanism and a control mechanism for distributing castings to the finishing mechanism.

[0045] The conveying mechanism includes a column 21. A cylindrical platform 2 is installed on the top surface of the column 21, and the top surface of the platform 2 is parallel to the ground. A turntable 22 with a circular cross section is installed on the column 21 under the platform 2, and The central axis of the turntable 22, the central axis of the platform 2 and the central axis of the column 21 coincide, the diameter of the platform 2 is smaller than the diameter of the turntable 22; four sets of casting finishing electric push rods 4 are installed on the turntable 22, and each set of casting finishing electric push rods 4 includes two electric push rods 41 of the same size and arranged symmetrically along a sym...

Embodiment 2

[0066] Example 2. Such as Figure 7-9 As shown, the difference between this embodiment and the first embodiment is that a dust collector 17 is provided on the finishing module of other castings. The ring-shaped casting multi-station grinding machine 75 has three stations each.

Embodiment 3

[0067] Example 3. Such as Figure 10-13 As shown, the difference between this embodiment and Embodiment 1 is that the ring-shaped casting multi-station grinder 75 is provided with four stations each.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com