Automatic plate material finely cutting system

A precision shearing and sheet metal technology, which is applied in the direction of shearing equipment, shearing devices, and accessories of shearing machines, etc., can solve problems such as inability to cut steel plates, unsmooth adjustment of steel plate positions, and deformation of steel plates during cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0028] The existing palletizing robot described in this application is mainly composed of the existing public robot and the end picker. The end picker is mainly a vacuum suction cup, and the vacuum suction cup is used as the execution end. Plates that need to be trimmed.

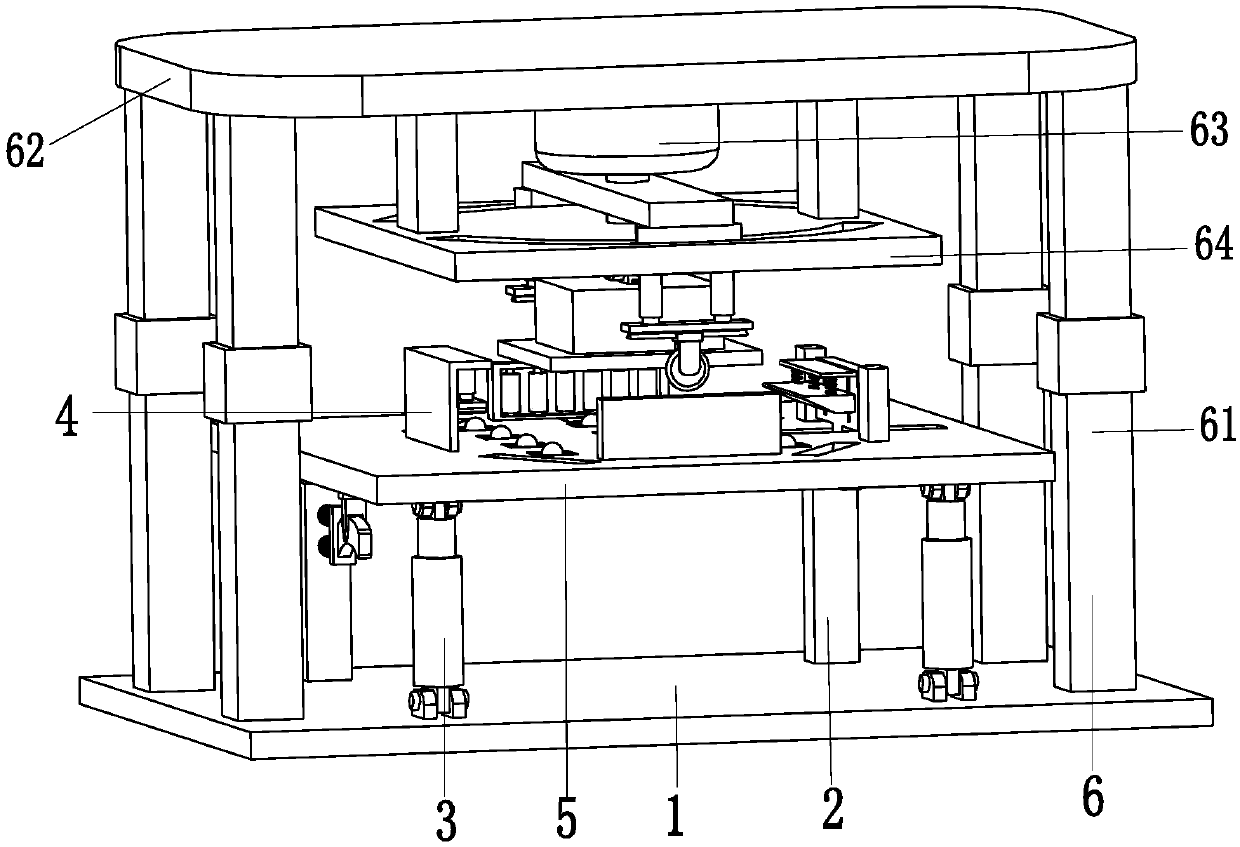

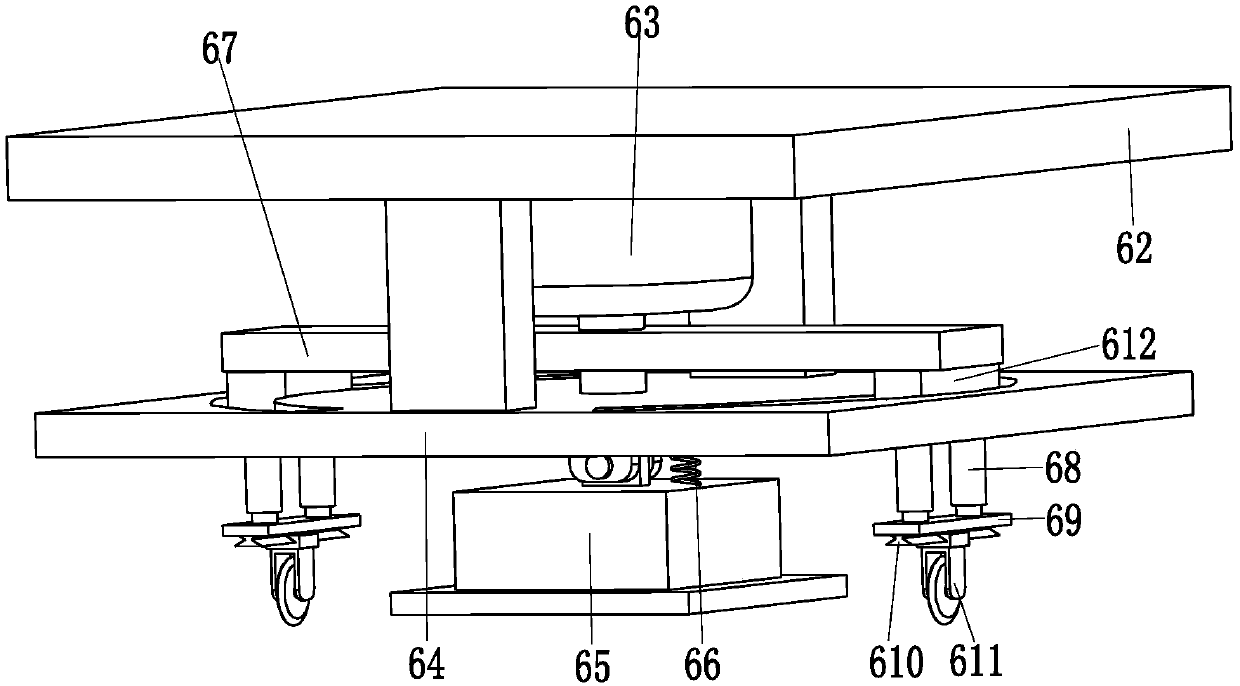

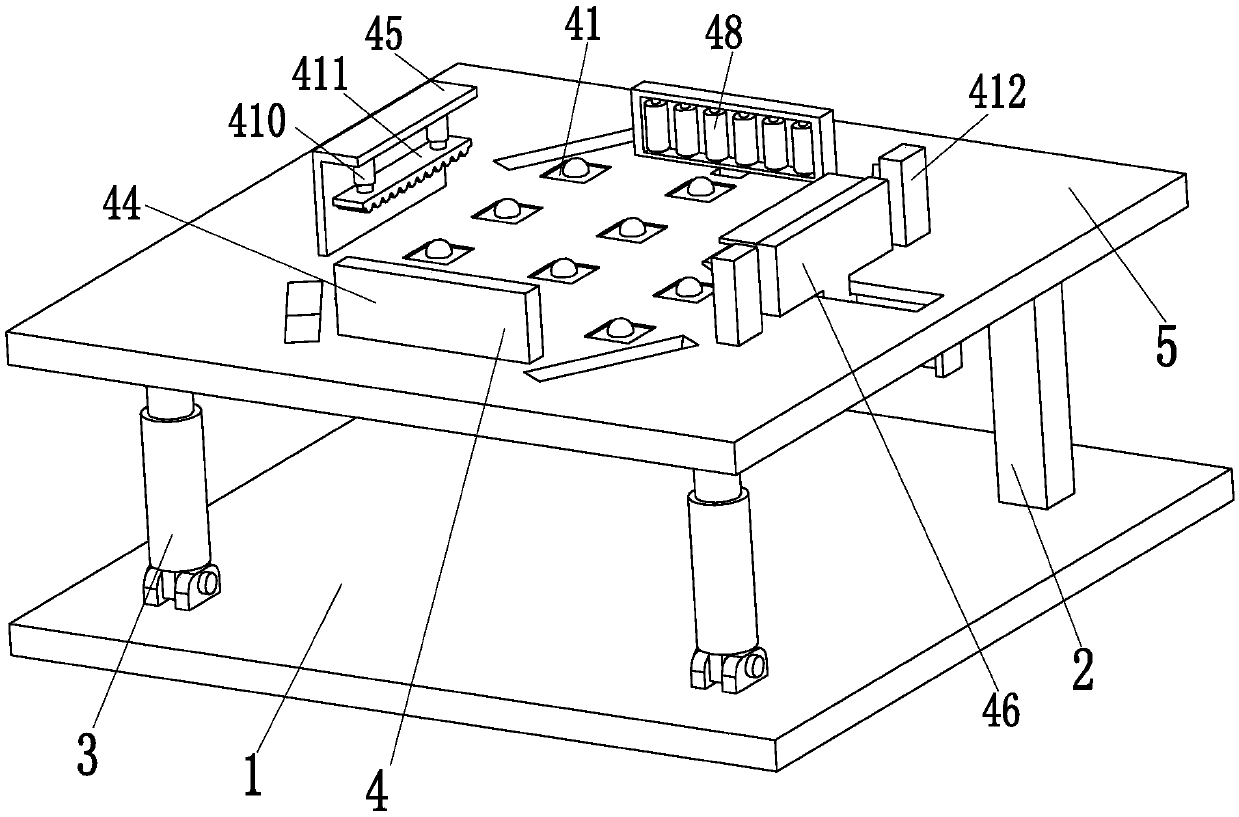

[0029] Such as Figure 1 to Figure 9 As shown, a sheet metal automatic precision shearing system includes a support base plate 1, a support column 2, an angle hydraulic cylinder 3, a positioning device 4, a positioning support plate 5 and a cutting device 6, and the rear end top of the support base plate 1 is The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com