Mesoporous titania-silica oxide composite material, preparation method therefor and application of mesoporous titania-silica oxide composite material

A technology of mesoporous titanium oxide and composite materials, applied in catalyst activation/preparation, chemical instruments and methods, separation methods, etc., can solve the problems of small specific surface area, low photocatalytic activity, and high electron-hole binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A mesoporous titanium oxide-silicon oxide composite material with a pore diameter of 9.2-10.6nm and a specific surface area of 257-356m 2 / g, the volume ratio of the anatase phase in the titanium oxide species to the total titanium oxide species is 93.2-99.5%.

[0036] The invention discloses a method for preparing the above-mentioned mesoporous titanium oxide-silicon oxide composite material, which specifically includes the following steps:

[0037] (1) Add 5.1g of P123 into 180ml of 1.0M HCl, stir and dissolve at room temperature, and after equilibrating at 35°C for 30min, add 0.06g of NH 4 F;

[0038] (2) After pre-mixing 30 g of n-nonane, 8 g of ethyl orthosilicate, and 12 g of n-butyl titanate, they were added to the reaction solution obtained in step (2), and then hydrolyzed at 35° C. for 24 hours;

[0039] (3) Transfer the reaction solution obtained in step (2) to a hydrothermal kettle for hydrothermal treatment at 120° C. for 24 hours;

[0040] (4) Filter t...

Embodiment 2-5 and comparative example 6-7

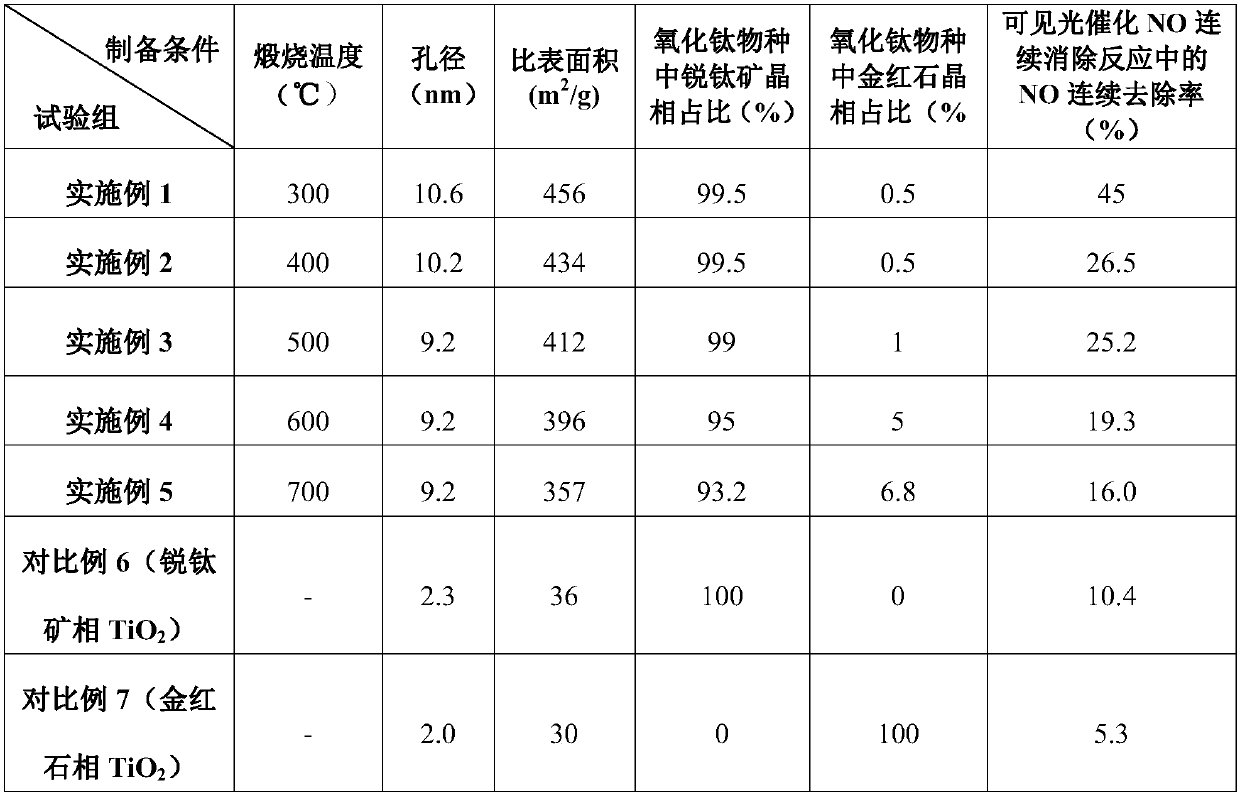

[0049] The calcination temperature of Examples 1-5 is controlled, and the calcination temperature and catalytic effect of each embodiment are shown in Table 1 below.

[0050] Table 1

[0051]

[0052] in conclusion:

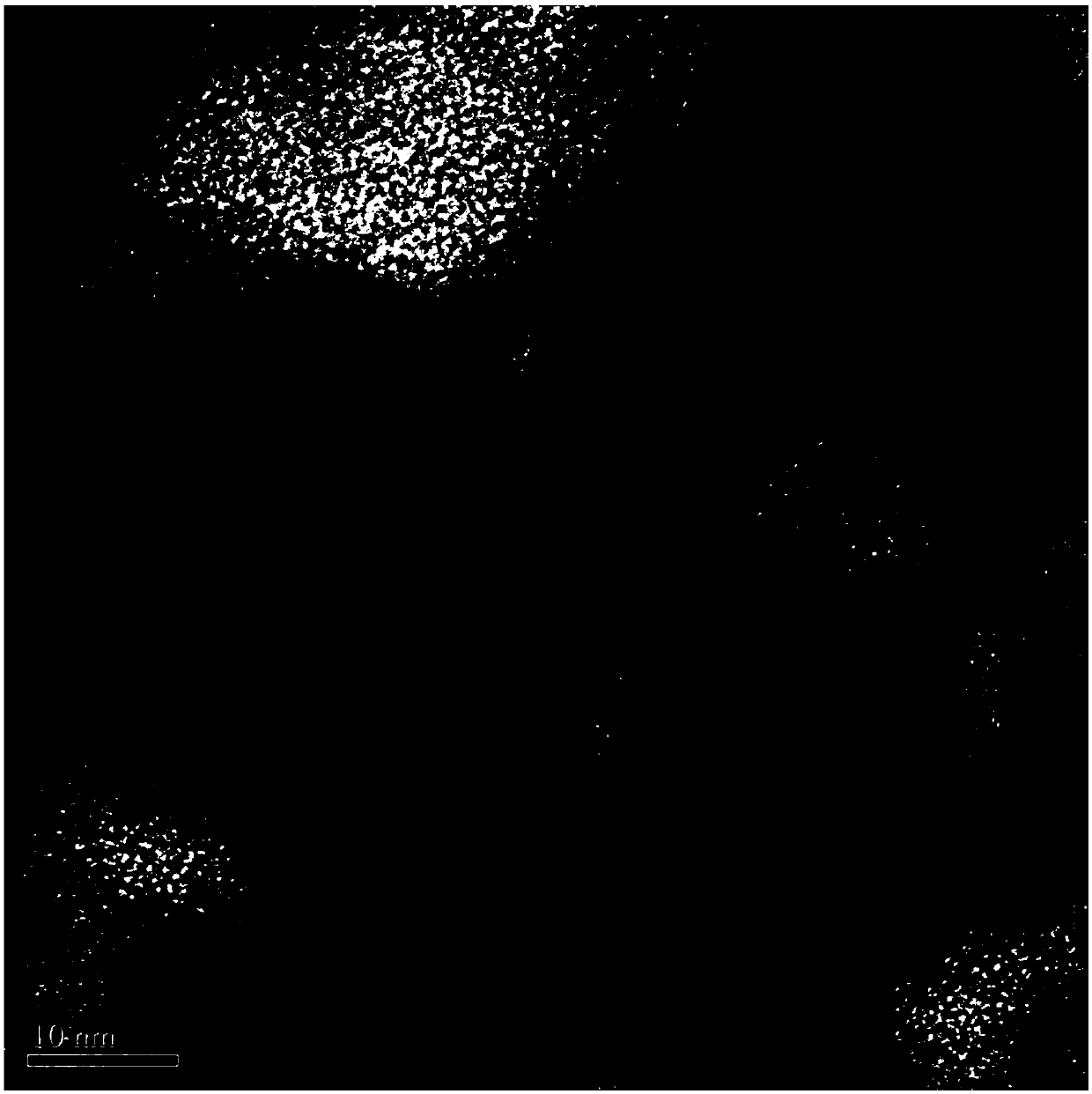

[0053] (1) from figure 1 From the transmission electron microscope (TEM) image of the composite material obtained in Example 1 shown in , it can be found that titanium oxide particles in the material obtained in Example 1 are uniformly dispersed in silicon oxide. The size of titanium oxide particles is relatively uniform, about 5nm×10nm;

[0054] (2) It can be drawn from Examples 1-3 that the present invention synthesizes a kind of mesoporous titanium oxide- Silicon oxide composite material. The pore diameter of these materials is 9.2-10.6nm, which is a typical mesoporous material; the specific surface area is 257-356m 2 / g, significantly exceeding the specific surface area of pure titanium oxide material.

[0055] (3) from figure 2 As shown in the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com