High-speed-rotation atomizer with vibration protection function

A technology with high-speed rotation and protective functions, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as not considering the shear force of the atomizer, severe vibration of the atomizer, unbalanced vibration of the atomization wheel, etc. Achieve the effects of shortening braking time, increasing work efficiency and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

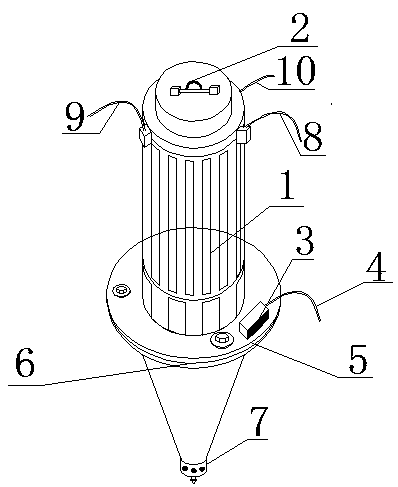

[0031] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0032] see figure 1 , a high-speed rotary atomizer with vibration protection function according to the present invention, comprising an atomizer body 1, a support flange 5 and a controller, a vibration measuring device 3 is installed on the top of the support flange 5, and the atomizer body 1 Lifting lugs 2 are installed on the top, and an electric hoist can be installed on the top of the desulfurization tower to carry out hoisting work for installation and maintenance of the atomizer.

[0033] The top of the atomizer body 1 is also connected with a slurry pipeline inlet pipe 8, an oil system inlet pipe 9 and a cooling water inlet pipe 10. The slurry to be atomized after mixing is mainly entered into the slurry channel inside the atomizer through the slurry pipeline inlet pipe 8 , due to the rotation of gears and bearings inside the atom...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com