Advanced oxidation system for treating organic waste gas and malodorous gas

An oxidation system, malodorous gas technology, applied in gas treatment, chemical instruments and methods, membrane technology, etc., can solve the problems of short survival time, low quantum yield, selective mineralization of organic pollutants, etc., to achieve the reaction system Stable, high oxidation efficiency, uniform effect of exhaust gas treatment device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

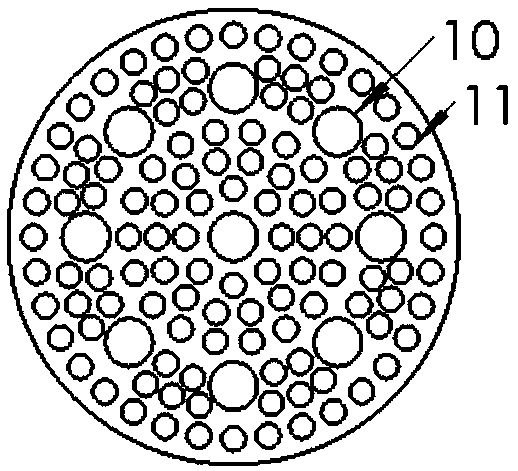

[0029] The embodiment provides an advanced oxidation system capable of generating multiple free radicals for processing organic waste gas and malodorous gas ( Figure 1~Figure 3 ), which includes:

[0030] Air supply duct 2, air supply duct 2 select a specific diameter according to a specific air volume, and select a specific material according to different working conditions;

[0031] Equipped with a certain concentration of persulfate solution tank 3, the persulfate solution is used to produce persulfate 4 - ·Sodium persulfate is generally used as SO 4 - ·Generation source, the concentration of persulfate solution is generally 4-20g / L according to the type and concentration of waste gas;

[0032] The 254nm UV lamp 4 is used to activate the persulfate to generate a certain amount of free radicals. The number of the 254nm UV lamp 4 is determined according to the amount of the persulfate solution; the 254nm UV lamp is made of waterproof material and has stronger penetration ability fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com