PLC controlled organic waste gas treatment equipment

A technology for organic waste gas and treatment equipment, applied in gas treatment, electrical program control, program control in sequence/logic controller, etc., can solve the problems of high maintenance cost, increased maintenance cost, waste of resources, etc., and reduce maintenance cost , Save labor cost, improve production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

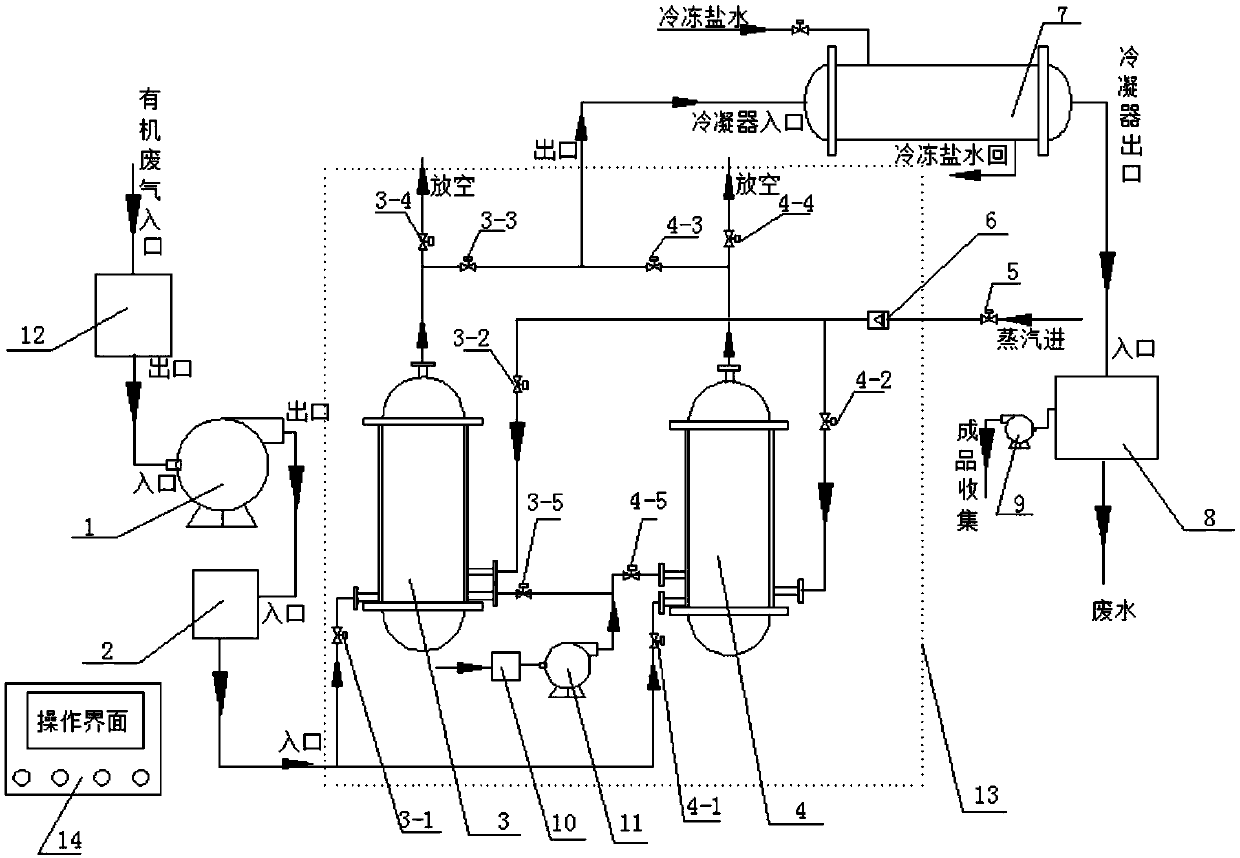

[0027] Combine below figure 1 and figure 2 And preferred embodiment the present invention is described in further detail.

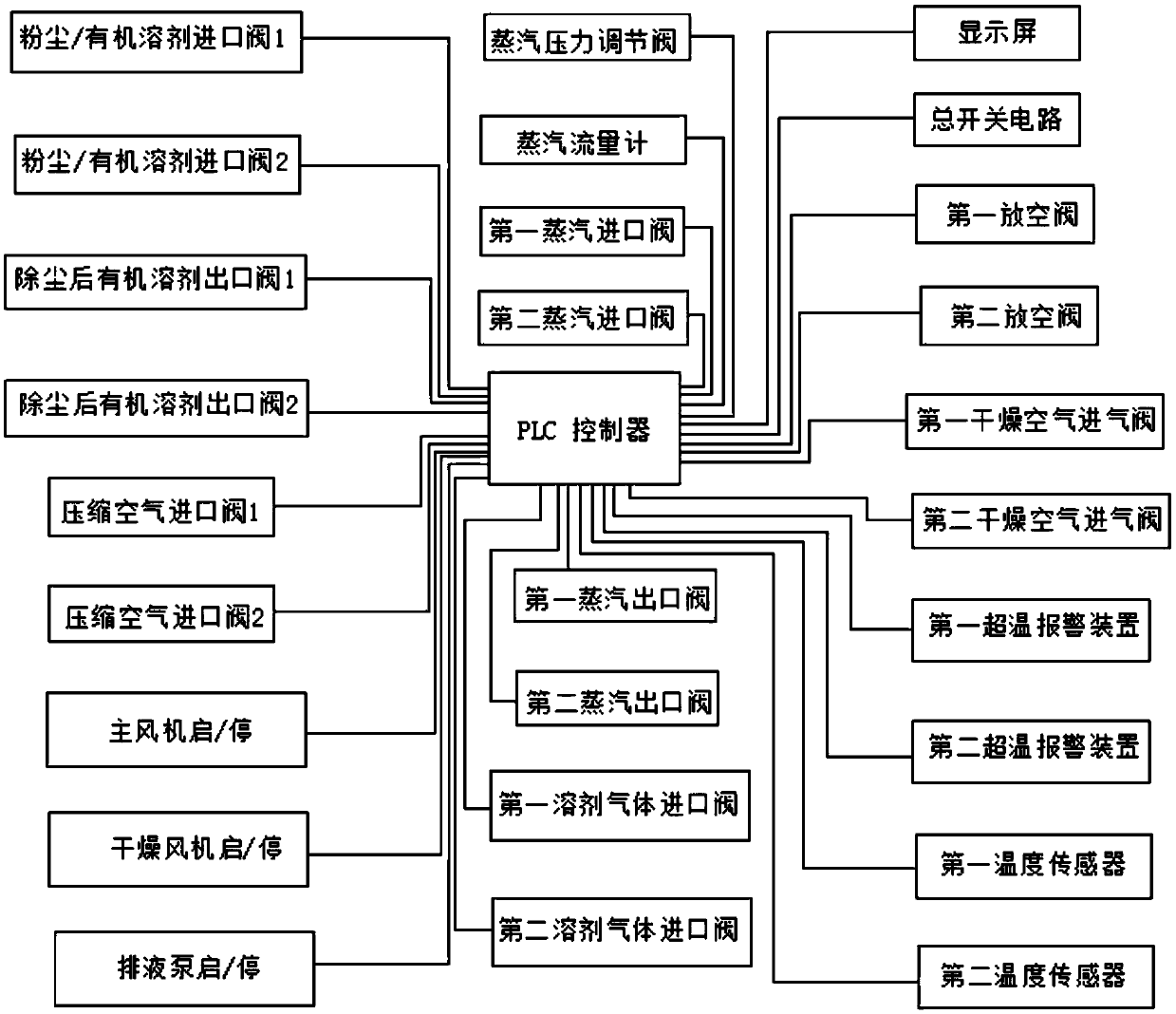

[0028] A PLC-controlled organic waste gas treatment equipment, including a dust removal system 12, a fan 1, a cooler 2, an adsorption system 13 (including two adsorption tanks 3 and 4), a condenser 7, a layered tank 8, and a PLC controller 14.

[0029] The inlet and outlet of the dust removal system 12 are respectively connected to the dust and organic waste gas inlet and the inlet of the fan 1, the outlet pipe of the fan 1 is connected to the inlet pipe of the cooler 2, and the inlet and outlet of the adsorption system 13 are connected to the outlet of the cooler 2 and the inlet pipe of the cooler 2 respectively. The inlet of the condenser 7 is connected, and the outlet of the condenser 7 is connected with the inlet of the stratification tank 8 . The PLC controller 14 is connected with each actuator through a data bus.

[0030] Adsorption tank 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com