An anti-galling torsional eddy current mass damper and its optimization method

A technology of mass damper and optimization method, which is applied in the installation of electrical components, cables, overhead installation, etc., can solve the problem of increasing the durability of the spacer bar, the suppression of galloping is not significant, and the torsional damper without anti-dancing is reported in literature and practical application. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The present invention is described in further detail with reference to the accompanying drawings and specific embodiments.

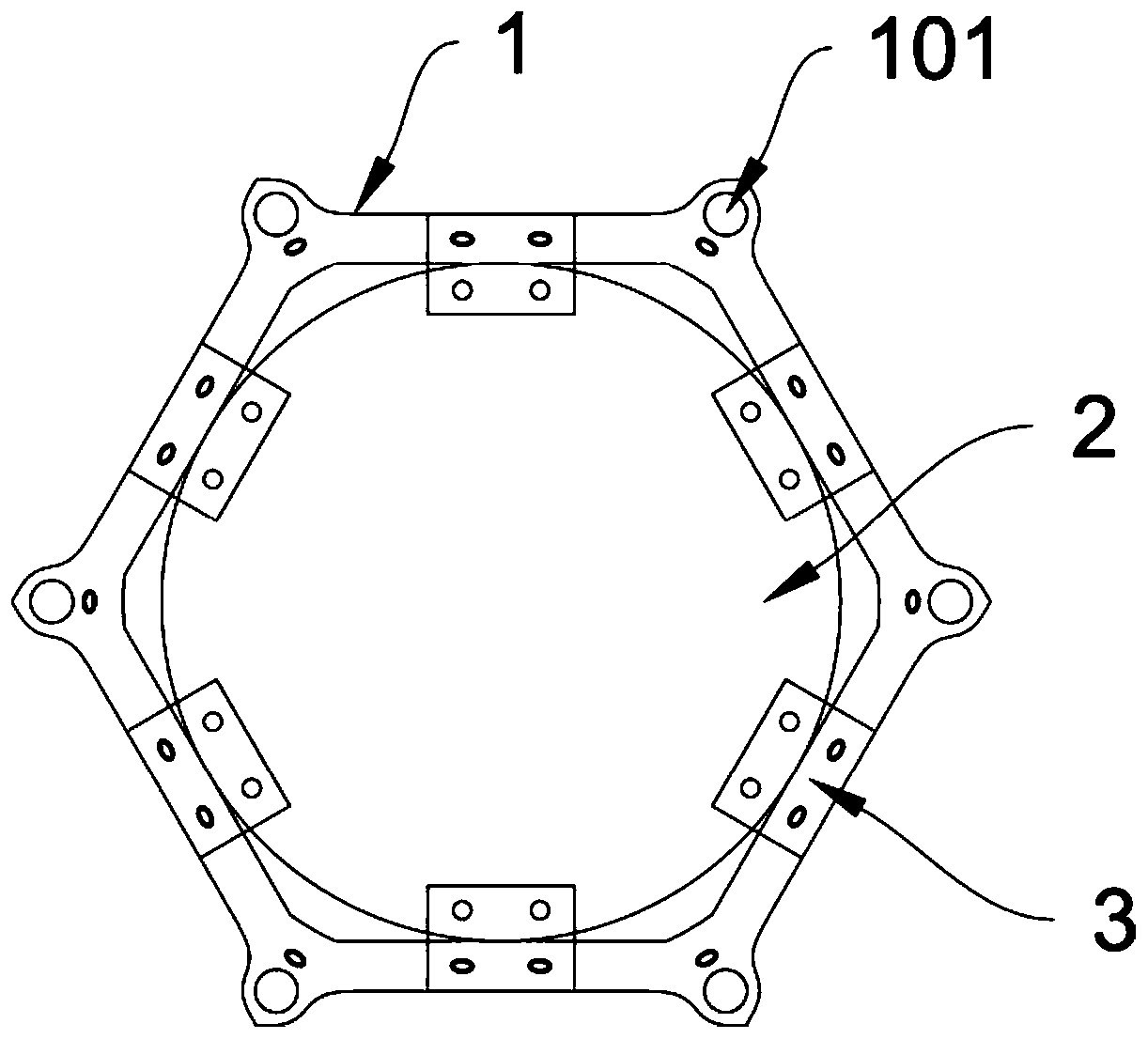

[0076] The anti-dancing torsion steering eddy current mass damper 2 is taken as a whole, and its size is coordinated with the size of the sub-wire spacer 1, and the split wire is passed through the hole 101 of the sub-wire spacer 1. The sub-conductor spacer 1 is fixed with the fixed connecting piece 3, so that the housing 4 of the damper and the sub-conductor spacer 1 are rotated synchronously.

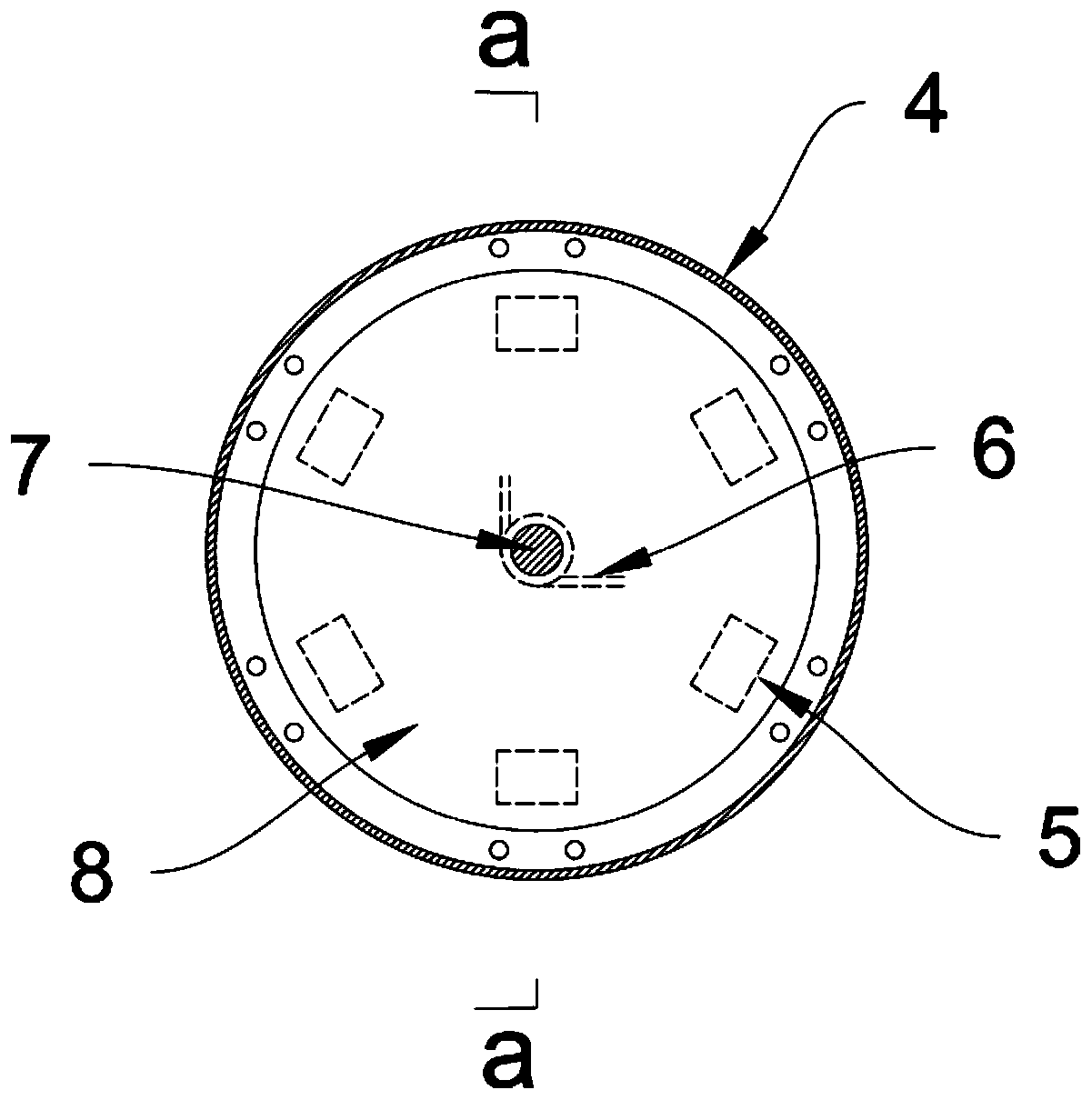

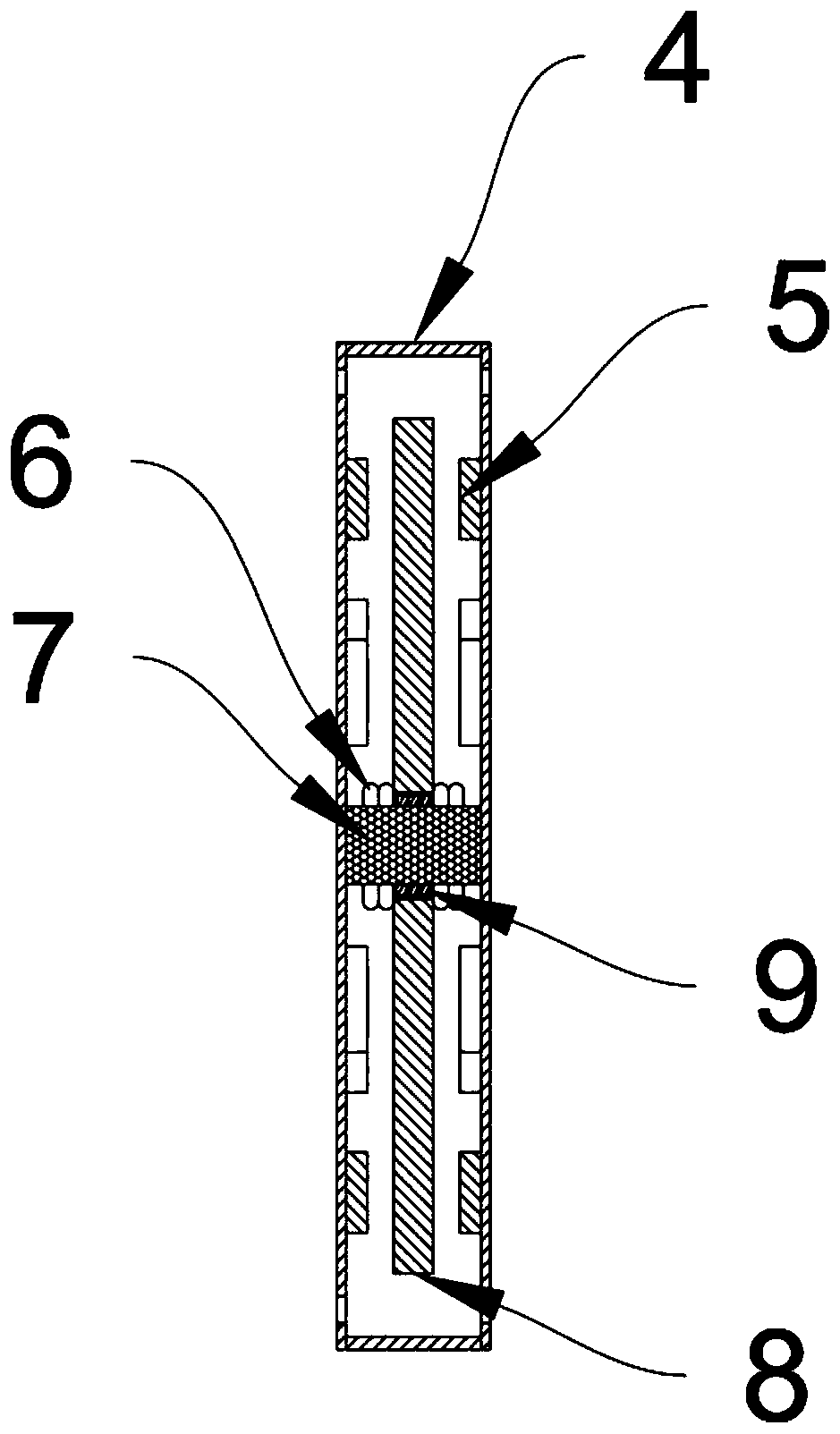

[0077] Inside the anti-dancing torsion steering eddy current mass damper 2, a power transmission shaft 7 is installed first, and the torque is transmitted between the power transmission shaft 7 and the housing 4 of the damper, and the torque is synchronously rotated. The torsion bearing 9 is used to connect the power transmission shaft 7 and the metal disc 8, and the torsion bearing 9 does not transmit torque and has no friction. A plurality of permanent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com