Anti-counterfeiting film

A technology of anti-counterfeiting film and film stack, applied in the field of anti-counterfeiting film, can solve the problems of high cost and difficult production process of anti-counterfeiting film, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

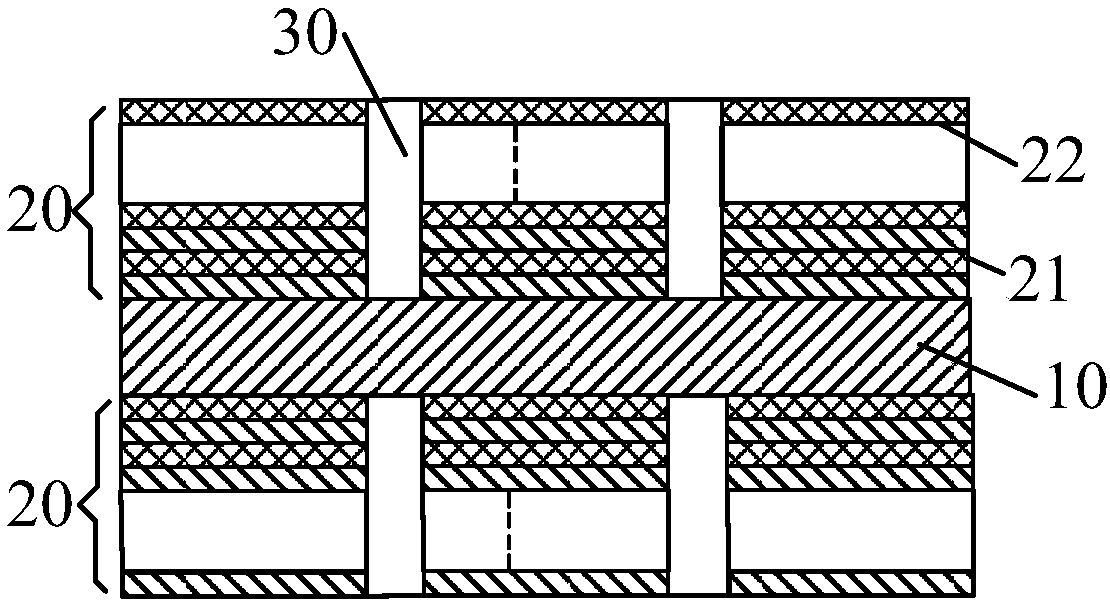

Embodiment 1

[0085] Simulation experiment data:

[0086] A PET layer with a thickness of 0.05 mm is used as the transparent substrate layer. A film stack of an anti-reflection layer and an anti-counterfeiting pattern layer (a layer of high refractive index material and a layer of low refractive index material cross-stacked) is set on the PET layer, wherein the shape of the film stack is set to "KDX", and the film stack The hollowed-out gaps are filled with PET, the central wavelength of the incident light is set to 532nm, the high refractive index material layer is a titanium dioxide layer with a refractive index of 2.354, and the low refractive index material layer is a silicon dioxide layer with a refractive index of 1.46. The transparent layer is composed of a titanium dioxide layer and a silicon dioxide layer with an optical thickness of λ / 4, and the optical thickness coefficient of the anti-counterfeiting pattern layer is designed as:

[0087] 第一半膜堆:0.216H 1.836L 0.303H 1.691L 0.377H...

Embodiment 2

[0092] The two half-film stacks of the anti-counterfeiting film corresponding to Example 1 were fabricated by using the magnetron sputtering process, and the substrate was cleaned with a clean cloth and ethanol. Design the mask plate with clearance "KDX".

[0093] After degassing the vacuum chamber, use a vacuum cleaner to clean the inside of the bell jar, fill the molybdenum boat with the film material to be evaporated, and record the name of the film material of each boat. And place the substrate on the substrate holder, do not tilt the substrate, and place the mask plate on the cleaned substrate. Drop the bell jar and evacuate the vacuum chamber according to the operation rules of the coating machine. When the vacuum reaches 7×10 -3 After Pa, pre-melt the film material in the molybdenum boat in turn to remove the gas in the film material. At this time, pay attention to block the film material with a baffle to ensure that the substrate will not be plated during pre-meltin...

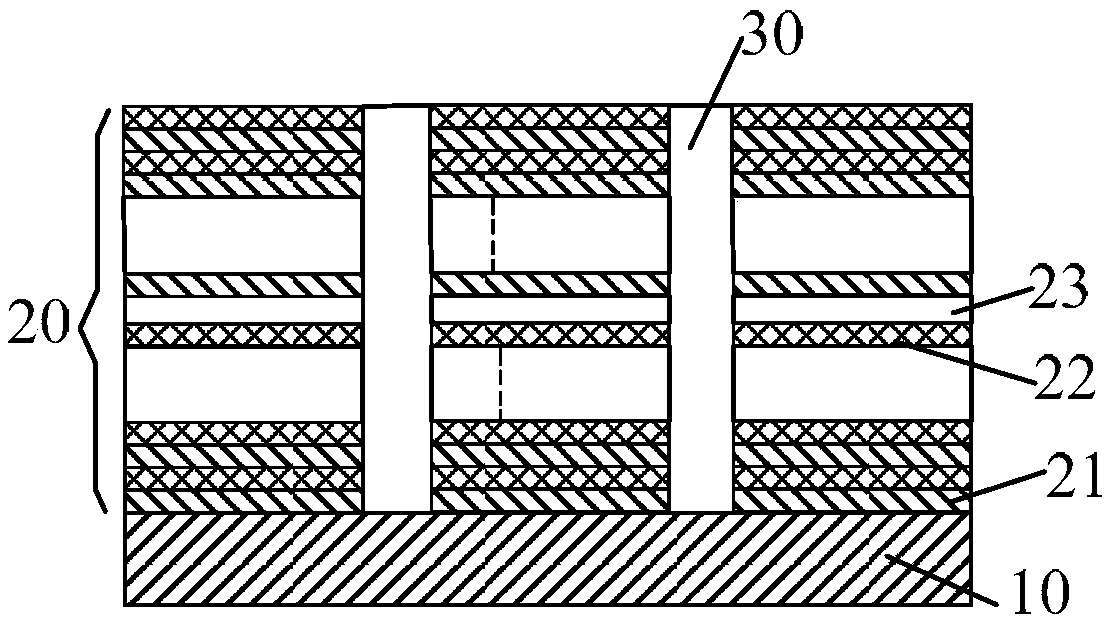

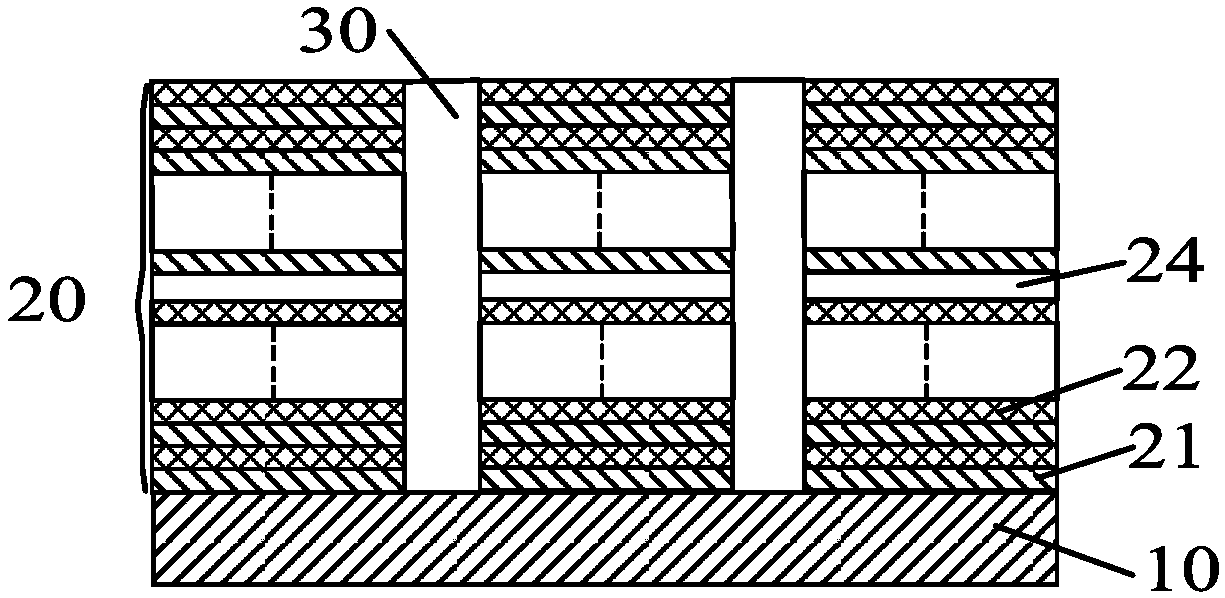

Embodiment 3

[0096] Simulation experiment data:

[0097] The optical thickness coefficient of the high-refractive index material layer and the optical thickness coefficient of the low-refractive index material layer of the film system are the same as in Example 1, and the two half-film stacks are arranged on two opposite surfaces of the PET layer. Using the Essential Macleod film system design software, from the vertical direction to the anti-counterfeiting film and the direction with an angle of 30° to the anti-counterfeiting film as the observation angle, the light reflection performance of the above-mentioned anti-counterfeiting film is simulated respectively. The simulation results are shown in Figure 7 and Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Physical thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com