Screw-in type pipeline connector

A connector and screw-in technology, which is applied in the direction of sealing surface connection, pipe/pipe joint/fitting, passing components, etc., can solve the problems of low connection reliability, complicated connection process, high failure possibility, etc., and achieve the overall structure Simple and compact, smooth connection process and small pipe deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

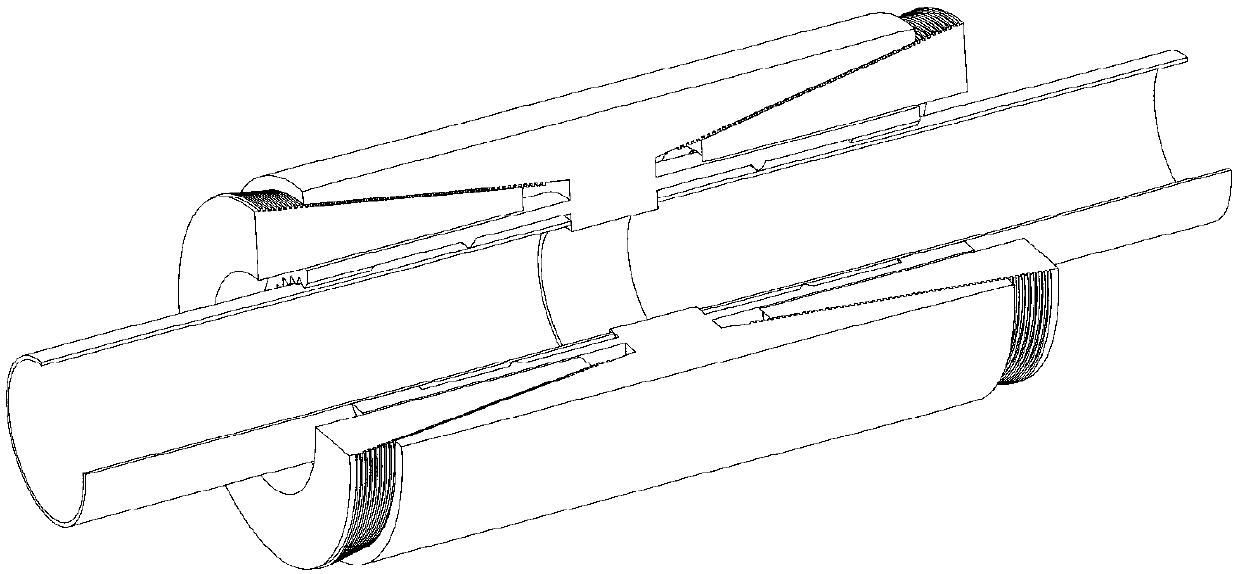

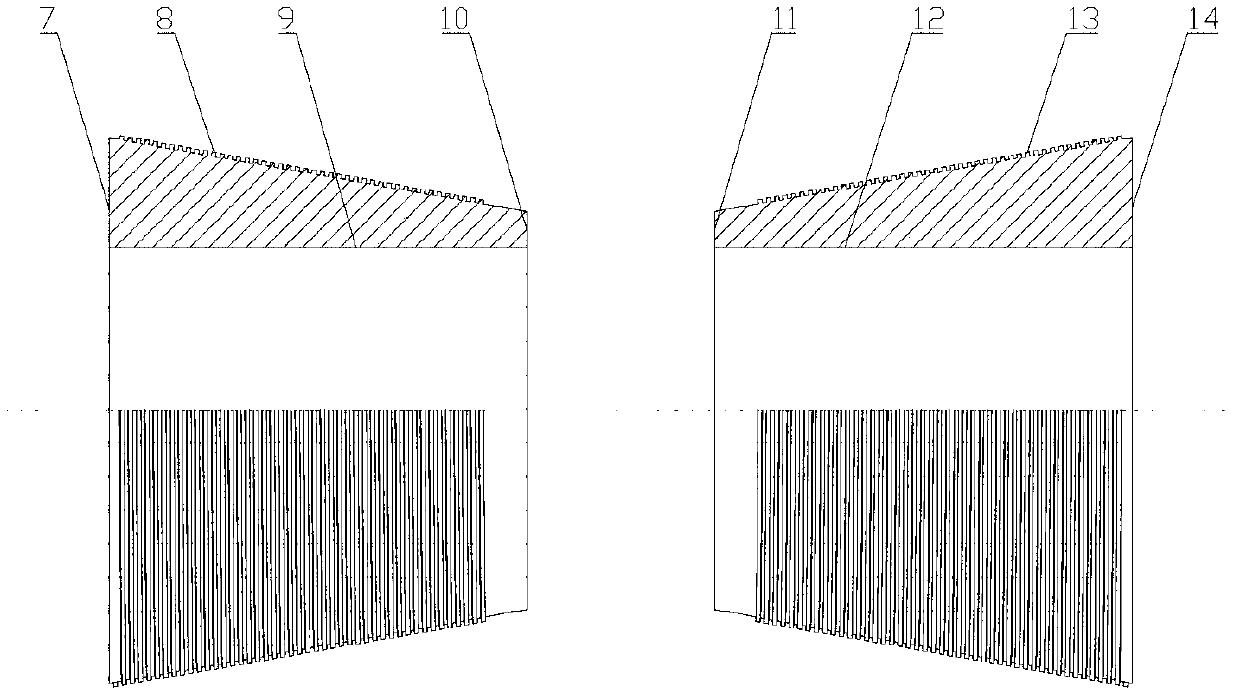

[0015] to combine Figure 1 to Figure 4 , the screw-in pipe connector of the present invention, when the connector is installed, first determine the position and size of the damaged pipe, determine the length of the cut pipe according to the size of the damage and prefabricate a new pipe with the same diameter, material and wall thickness, the new pipe The length is slightly shorter than the cut part, which is convenient for installation and docking of pipes during connection. Then, lower 4 pipe lifting racks from the workboat and adjust them to the designated positions. The pipe lifter lifts the pipe some distance away from the seabed. Use the pipe cutting machine to cut the pipe at the predetermined position, and recover the cut pipe to the operation ship through the cable. Lower the prefabricated pipeline from the workboat, lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com