A self-moving multi-directional fast roadway filling device

A filling device and self-moving technology, which is applied in the direction of fillings, safety devices, mining equipment, etc., can solve the problems of being unable to ram immediately, unable to walk by itself, and low filling rate, so as to speed up the moving speed and improve the overall filling rate. , the effect of a wide range of application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070]The present invention will be described in detail below with reference to the accompanying drawings, and the following examples are explained to the present invention, and the present invention is not limited to the following embodiments.

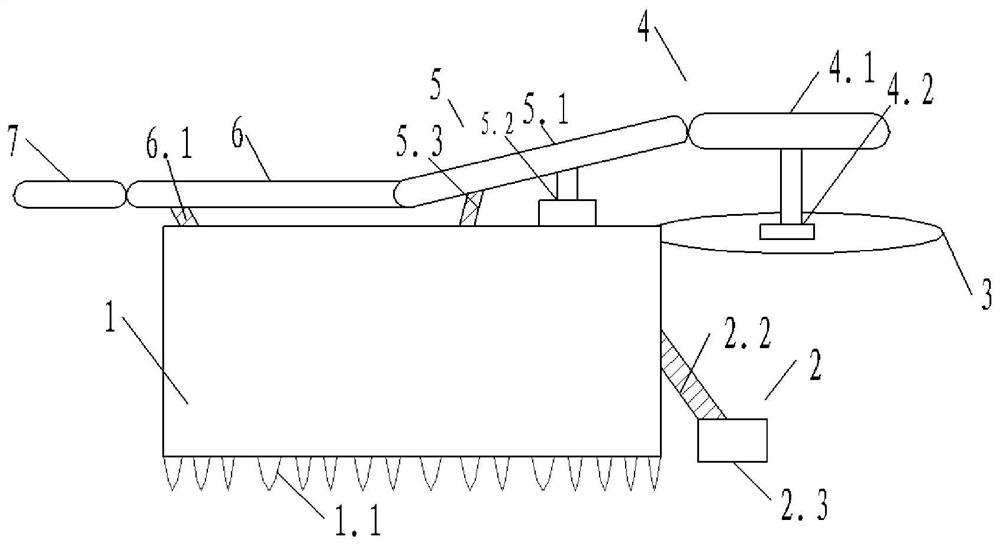

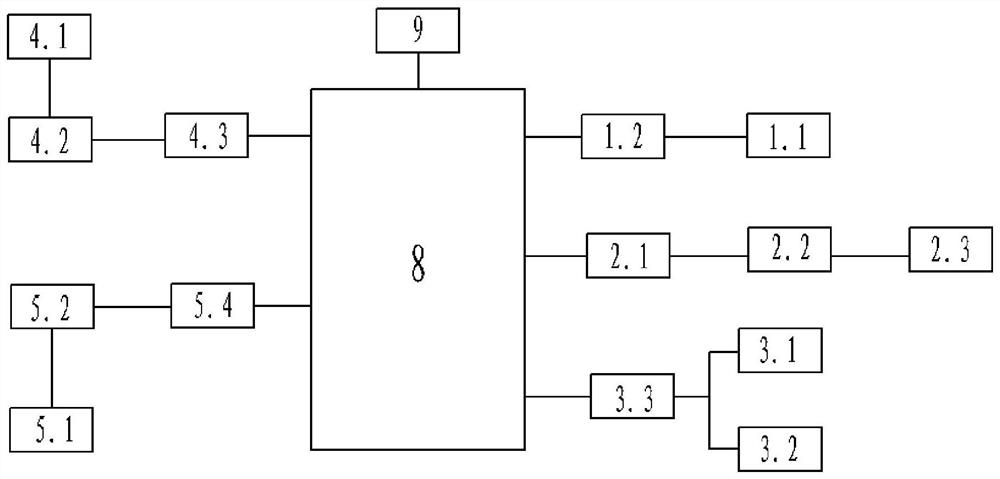

[0071]Such asfigure 1 with2As shown, a self-transition multi-directional lane filling device provided by the present invention, including:

[0072]The body assembly 1, the bottom of the body assembly 1 is provided with walking track 1.1, the walking track 1.1 is driven by the walking hydraulic motor 1.2;

[0073]The lower side of the ontopic assembly 1 is provided with a striped structure 2, including a consolidated hydraulic motor 2.1, which is connected to a stamped hydraulic cylinder 2.2 by a hydraulic line, and the output end of the hydraulic cylinder 2.3 is connected to a tamper beam 2.3. ; Consolidate the filled vermiculite;

[0074]A rotary platform 3 is provided in front of the body assembly 1, the rotary platform 3 connected to the left-rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com