Method for controllably preparing manganese oxide with different structures by taking manganese terephthalate dihydrate as precursor

A technology of manganese phthalate and terephthalic acid, which is applied in the field of preparing manganese oxides with different structures by hydrothermal method, can solve the problems of single type of product, destruction of complex skeleton, single reaction conditions, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

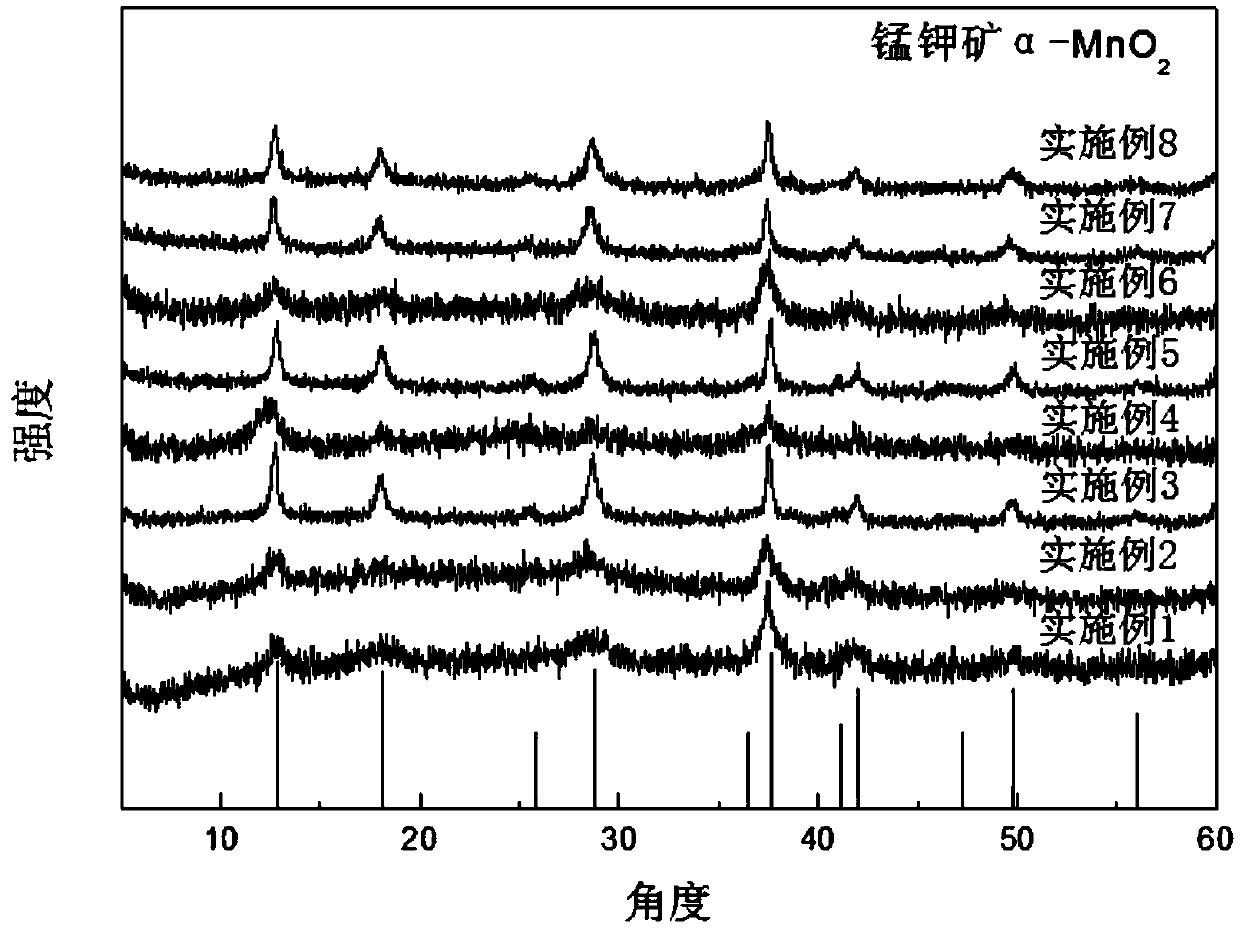

[0024] Add 0.025g (0.157mmol) of potassium permanganate and 0.080g (0.314mmol) of manganese terephthalate dihydrate into a glass bottle with a Teflon lid, and then add 10mL of H 2 SO 4 Aqueous solution, stirred and mixed evenly, left to react for 3.5 days at 85°C under airtight conditions, cooled naturally to room temperature, poured out the supernatant, washed the solid product at the bottom with 0.1mol / L NaOH aqueous solution, centrifuged, and cooled at 60°C Dry to constant weight to get 2×2 tunnel-type manganite α-MnO 2 . Depend on figure 1 It can be seen that the powder X-ray diffraction curve of the product obtained is consistent with the standard PDF card, indicating that the product is manganese ore.

Embodiment 2

[0026] Add 0.025g (0.157mmol) of potassium permanganate, 0.080g (0.314mmol) of manganese terephthalate dihydrate, and 10mL of deionized water into a glass bottle with a polytetrafluoroethylene cover, stir and mix evenly. Stand at 85°C for 3.5 days, cool naturally to room temperature, pour out the supernatant, wash the solid product at the bottom with 0.1mol / L NaOH aqueous solution, centrifuge, and dry to constant weight at 60°C to obtain 2×2 Tunnel type manganese potash ore α-MnO 2 (See figure 1 ).

Embodiment 3

[0028] Add 0.050g (0.314mmol) of potassium permanganate and 0.080g (0.314mmol) of manganese terephthalate dihydrate into a glass bottle with a Teflon cover, then add 10mL of NaOH aqueous solution with pH=9, stir and mix well , standing at 85°C for 3.5 days under airtight conditions, naturally cooling to room temperature, pouring out the supernatant, washing the solid product at the bottom with 0.1mol / L NaOH aqueous solution, centrifuging, and drying at 60°C to constant weight, Get 2×2 tunnel type manganese α-MnO 2 (See figure 1 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com