An automatic palletizing and transporting device for edible mushroom boxes and its transporting method

A technology of edible mushroom boxes and transportation devices, which is applied in the directions of transportation, packaging, and object stacking, and can solve the problems of low automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

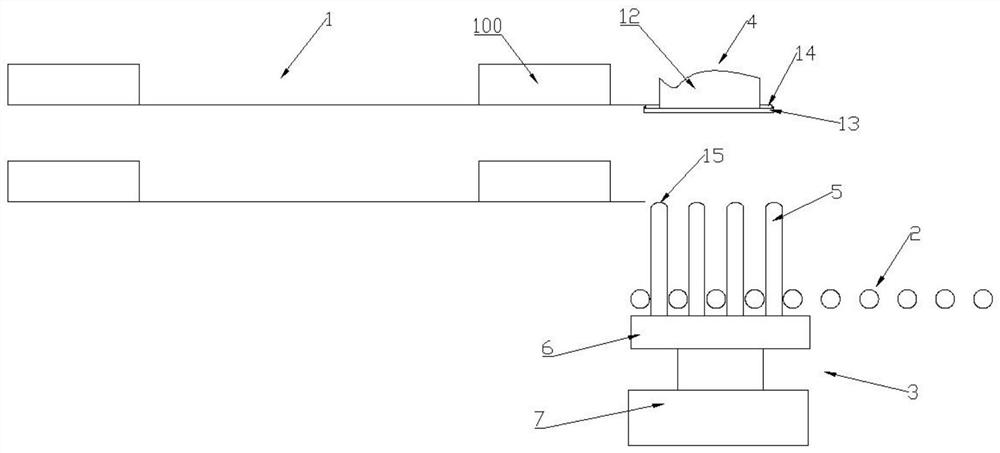

[0020] combine Figure 1 to Figure 5 A kind of edible fungus box automatic palletizing transportation device shown, in this embodiment, comprises double-deck conveyor 1, roller conveyor 2, lower palletizing assembly 3 and upper palletizing assembly 4, described double-deck conveyor It includes a frame, a lower conveyor fixed on the frame, and an upper conveyor located on the upper side of the lower conveyor, and the lower palletizing assembly 3 includes drive rollers inserted in the roller conveyor 2 Between at least two parallel support blocks 5, a base plate 6 fixed at the bottom of the support block 5, and a drive cylinder 7 that drives the base plate 6 up and down, and the support block 5 is used to support the Mushroom box 100, the top of the support block 5 passes through the driving roller of the roller conveyor 2 under the drive of the driving cylinder 7 and is flush with the end of the lower conveyor, and the upper layer The palletizing assembly 4 includes two pallet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com