High and low temperature adjustable three-dimensional printing forming equipment

A technology of three-dimensional printing and molding equipment, which is applied in biochemical equipment and methods, biochemical instruments, processing heating elements, etc., can solve the problems of fixed and unadjustable printing efficiency in molding space, energy waste, etc. High, improve the effect of printing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with each accompanying drawing, the present invention is described in detail:

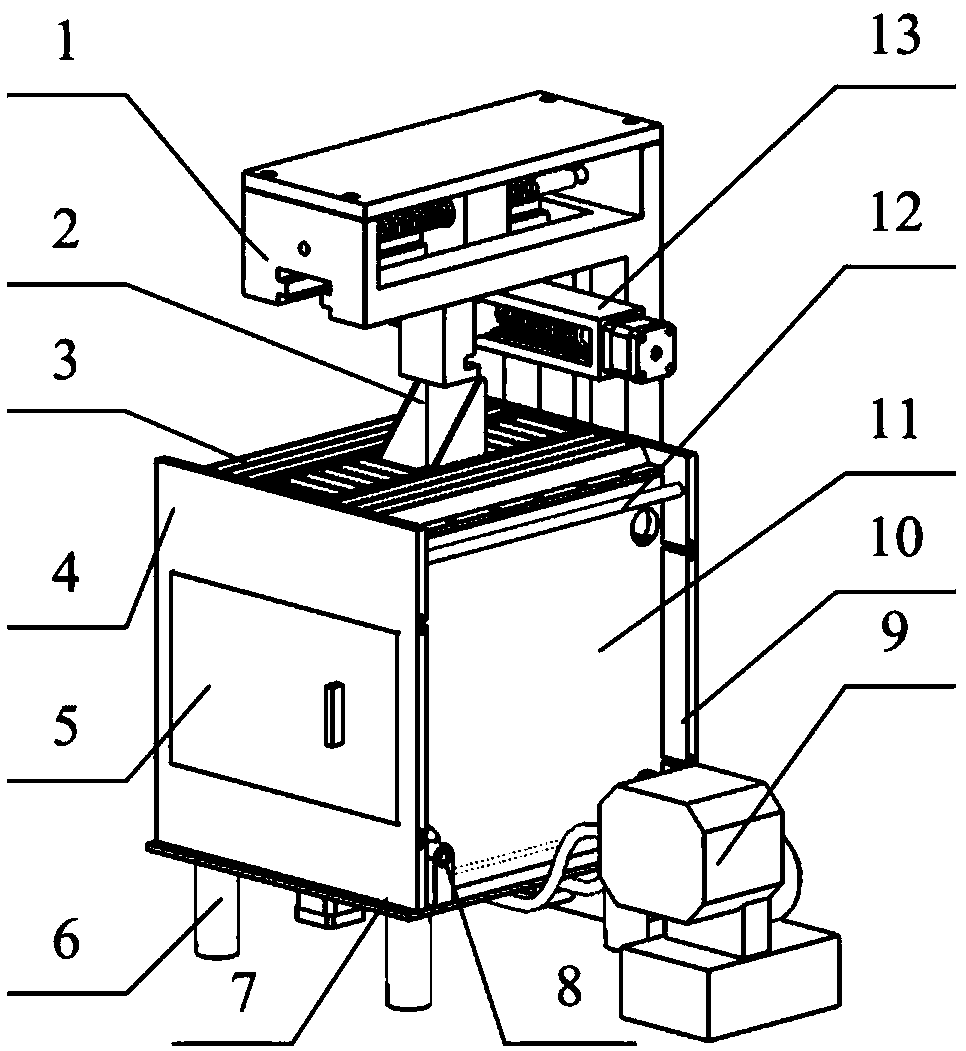

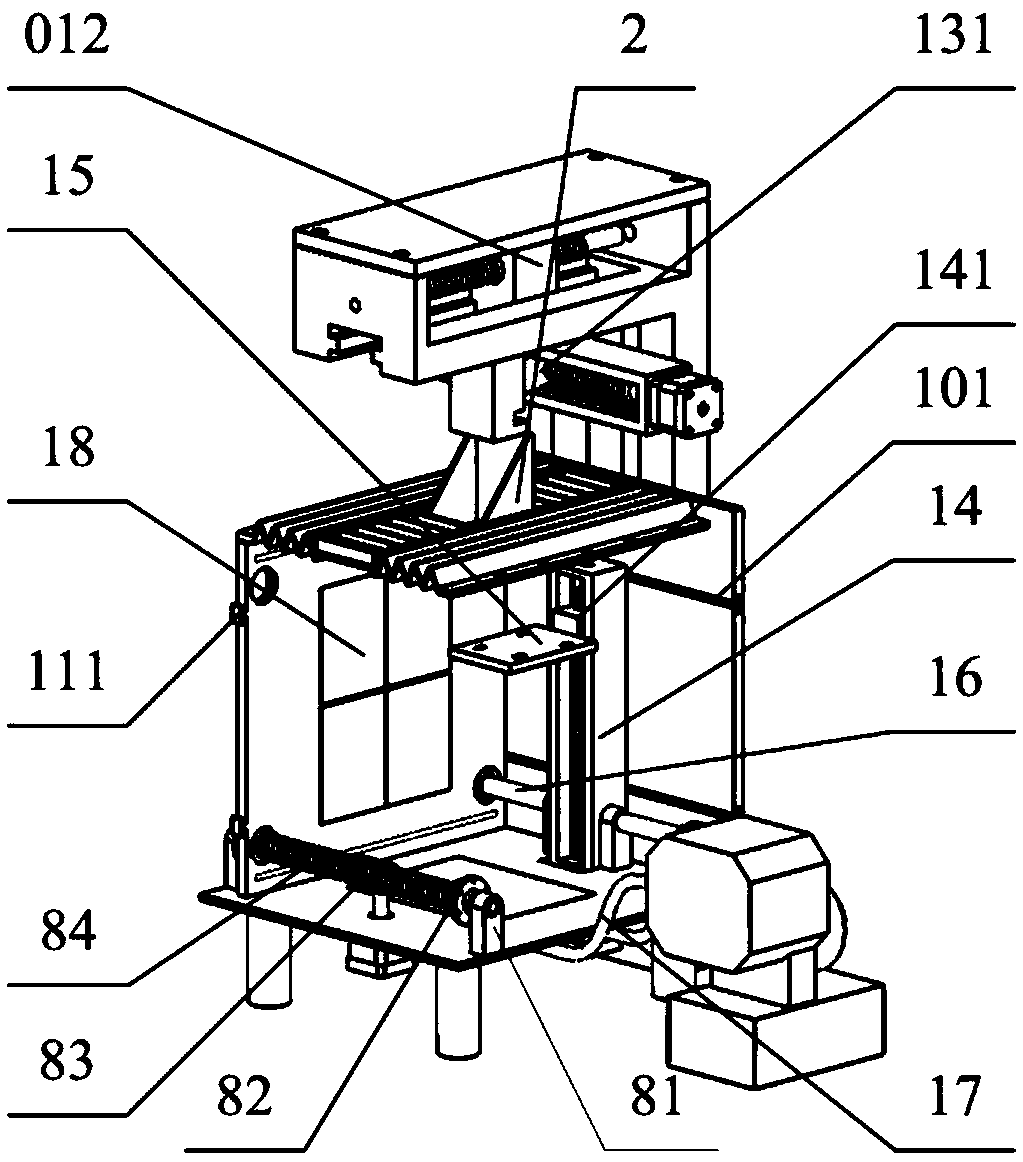

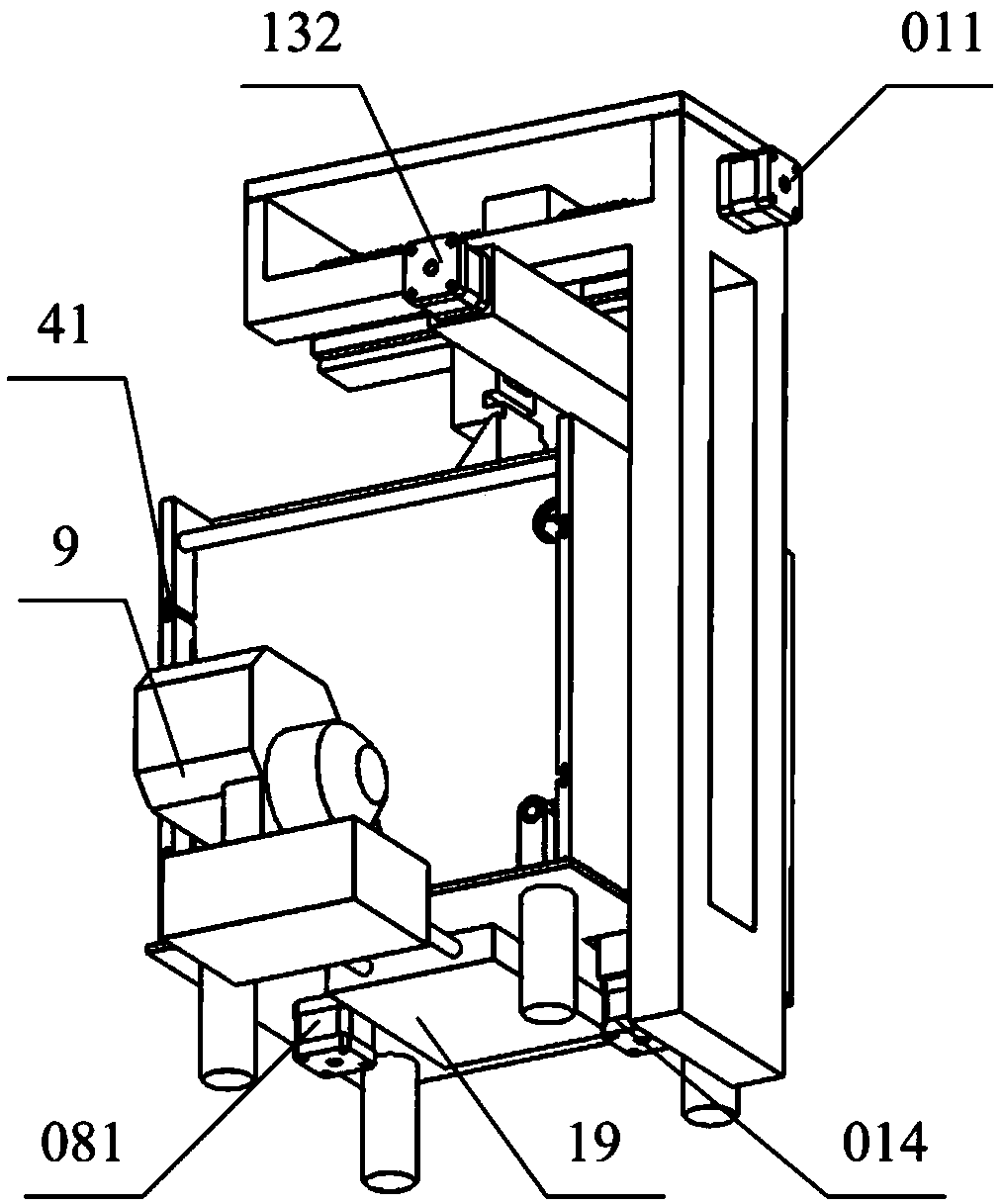

[0032] like Figure 1-4 As shown, a high and low temperature controllable three-dimensional printing molding device in this embodiment includes: a base 7, a molding chamber arranged above the base 7, an adjustment mechanism 8, a heating module, a printing module, a refrigeration module and a control module; the molding chamber It is composed of the upper panel 3, the front panel 4, the rear panel 10, the side panel 11 and the base 7; the heating module is installed on the wall of the molding chamber to heat the molding chamber; cooling; the printing module is arranged inside the molding chamber for printing products; the control module is arranged outside the molding chamber and is used for controlling the working process of the heating module or the cooling module.

[0033] like figure 1 As shown, the front panel 4 and the rear panel 10 vertically fix the front and re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com