Pipe fitting composite forming device

A technology of composite forming and pipe fittings, which is applied in the field of metal material processing and forming, and can solve problems such as failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

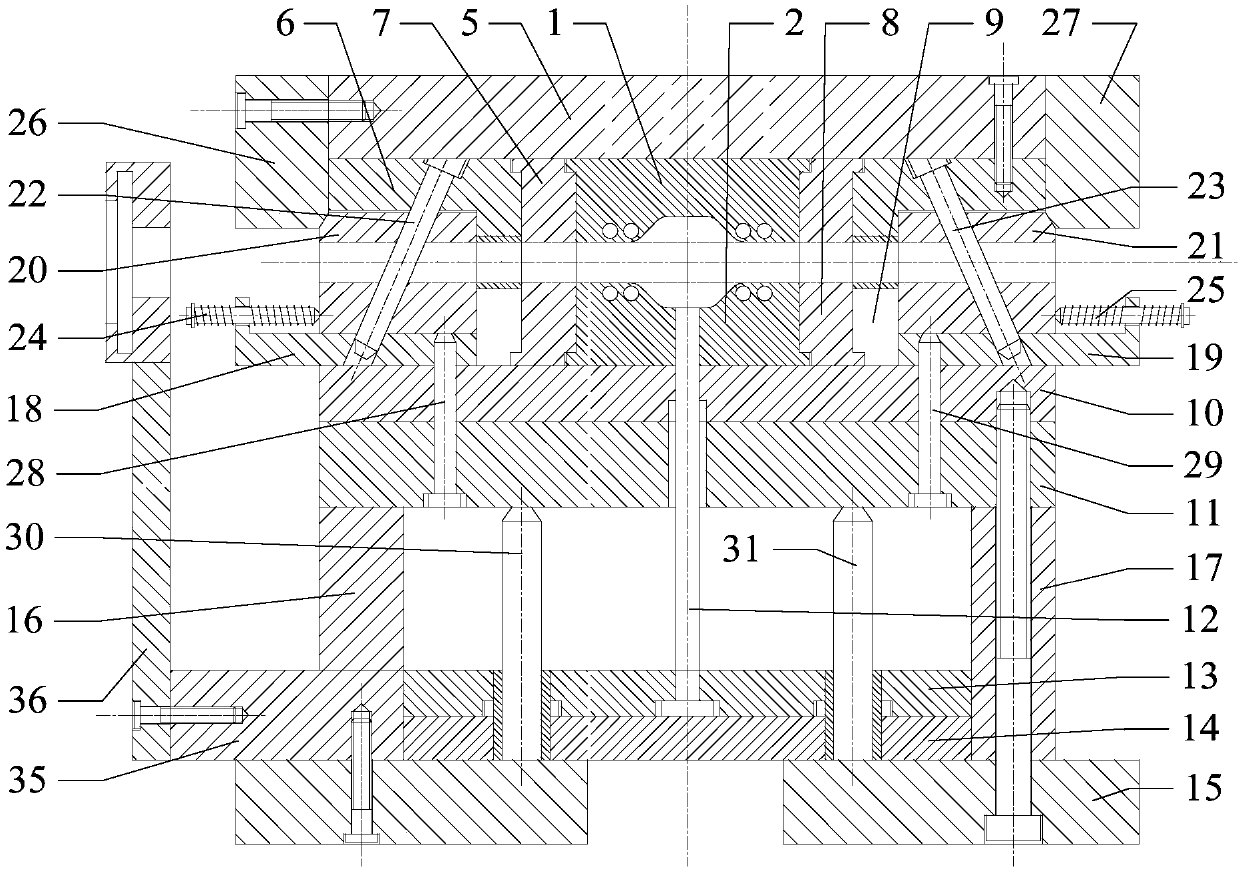

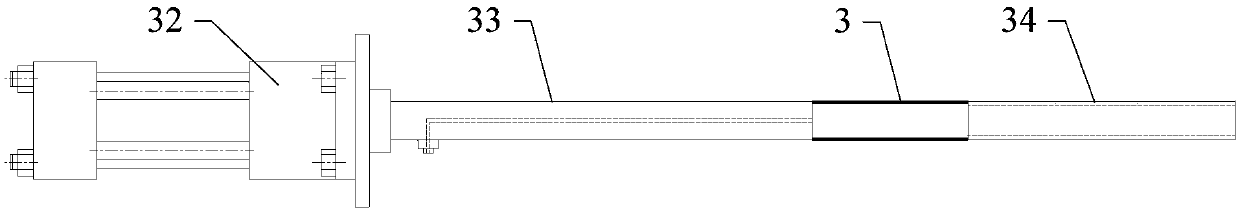

[0087] Embodiment: combine below Figure 1 to Figure 31 This embodiment will be described in detail.

[0088] The composite pipe forming device described in this embodiment includes a combined mold unit, a heating unit, a hydraulic unit, an axial feeding unit, an electromagnetic pulse generating unit and an impact unit;

[0089] The combined mold unit comprises an upper die 1 and a lower die 2, and an upper cavity is set indented on the bottom surface of the upper die 1, and a lower cavity is set indented on the top surface of the lower die 2, and the upper die 1 and the lower die 2 are vertically opposed and fixed, and the pipe fitting 3 to be formed is clamped horizontally between the upper die 1 and the lower die 2, and the upper cavity and the lower cavity together form the cavity of the combined mold unit;

[0090] The heating unit is used to heat the pipe fitting 3 to a predetermined temperature;

[0091] The hydraulic unit is used to inject the emulsion into the pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com