Method for conducting drug loading by adopting SC-CO2 (supercritical carbon dioxide) extraction device with GO (graphene oxide) or CNTs (carbon nano tubes) as carrier

An extraction device and carbon dioxide technology, which is applied in the direction of pharmaceutical formulas, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problem of low loading, and achieve the advantages of loading, avoiding pollution or separation problems , the effect of increasing drug loading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0037] Specific implementation mode 1: In this implementation mode, a supercritical carbon dioxide extraction device is used to carry out drug loading with GO or CNTs as a carrier according to the following steps:

[0038] Step 1: weighing the carrier, and placing the weighed carrier in the extraction tank of the supercritical extraction device;

[0039] Step 2: Weighing the drug, dissolving the weighed drug in absolute ethanol to obtain a mixed solution, and transferring the mixed solution to the entrainer tank of the supercritical extraction device;

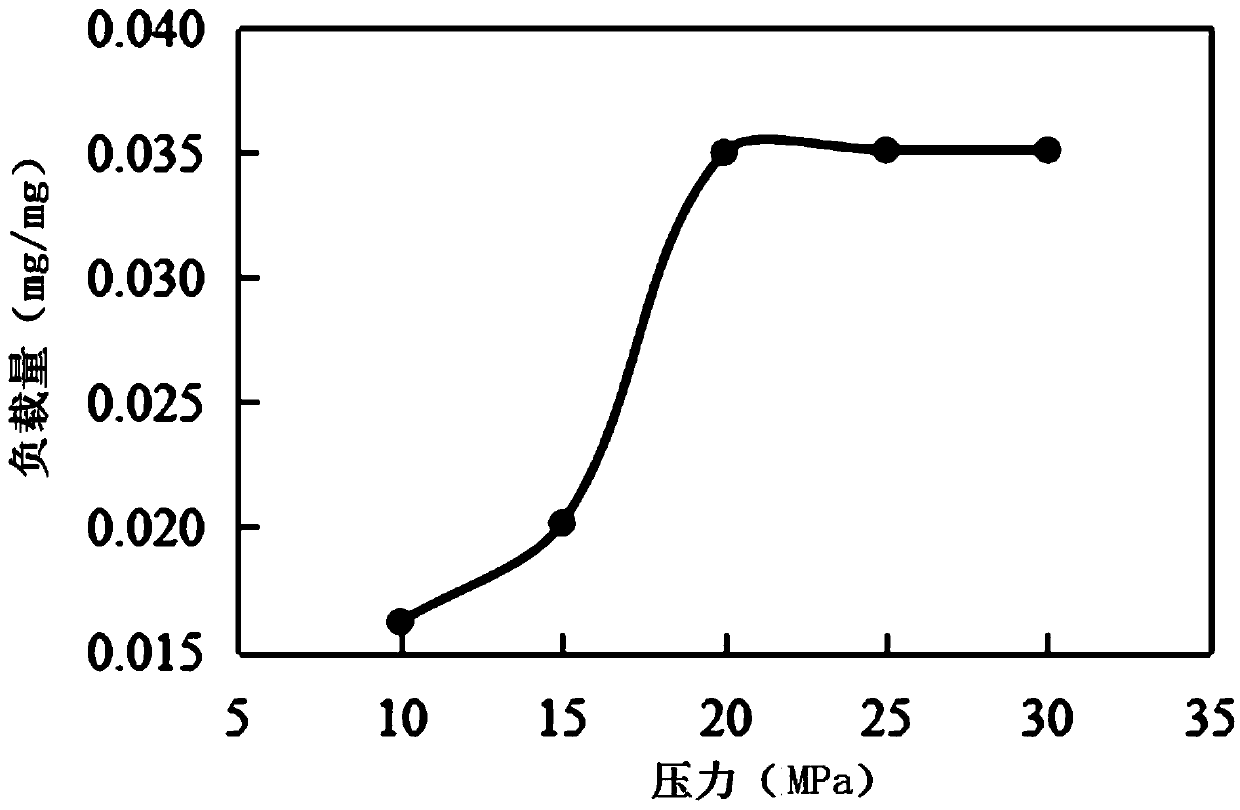

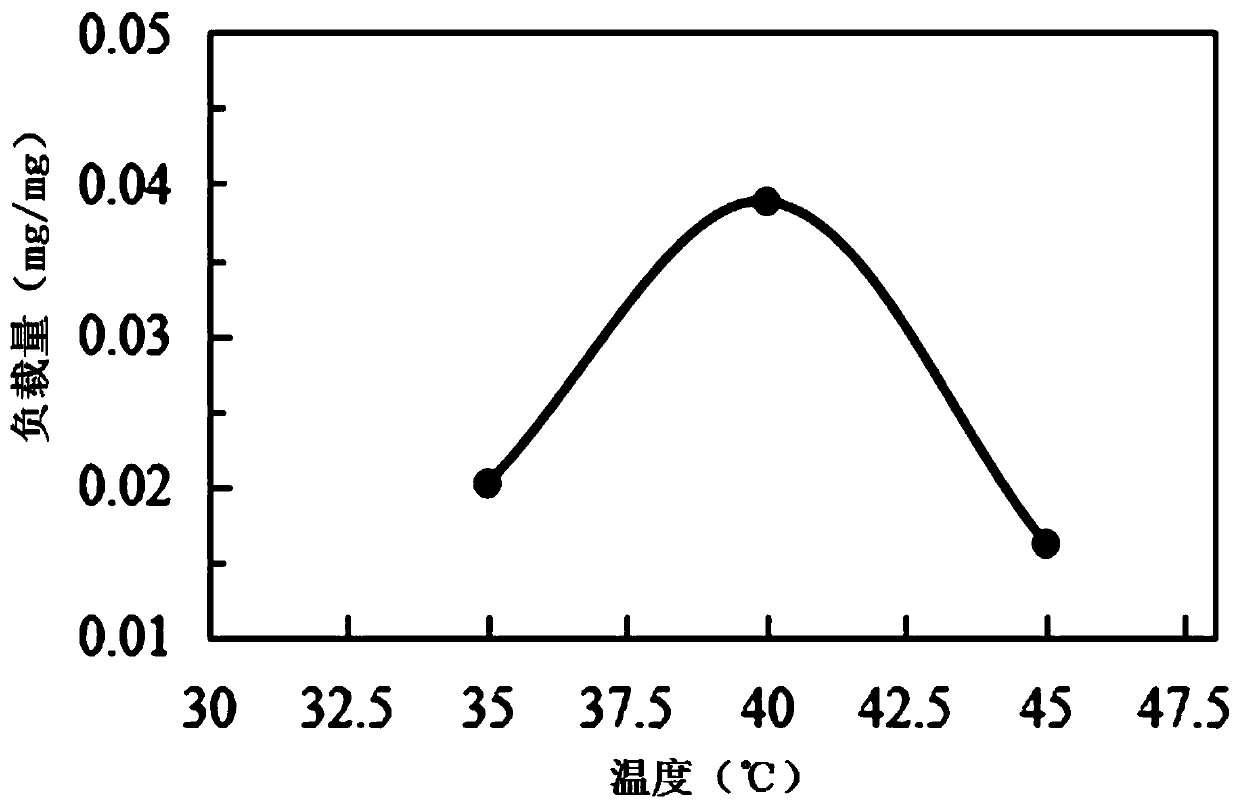

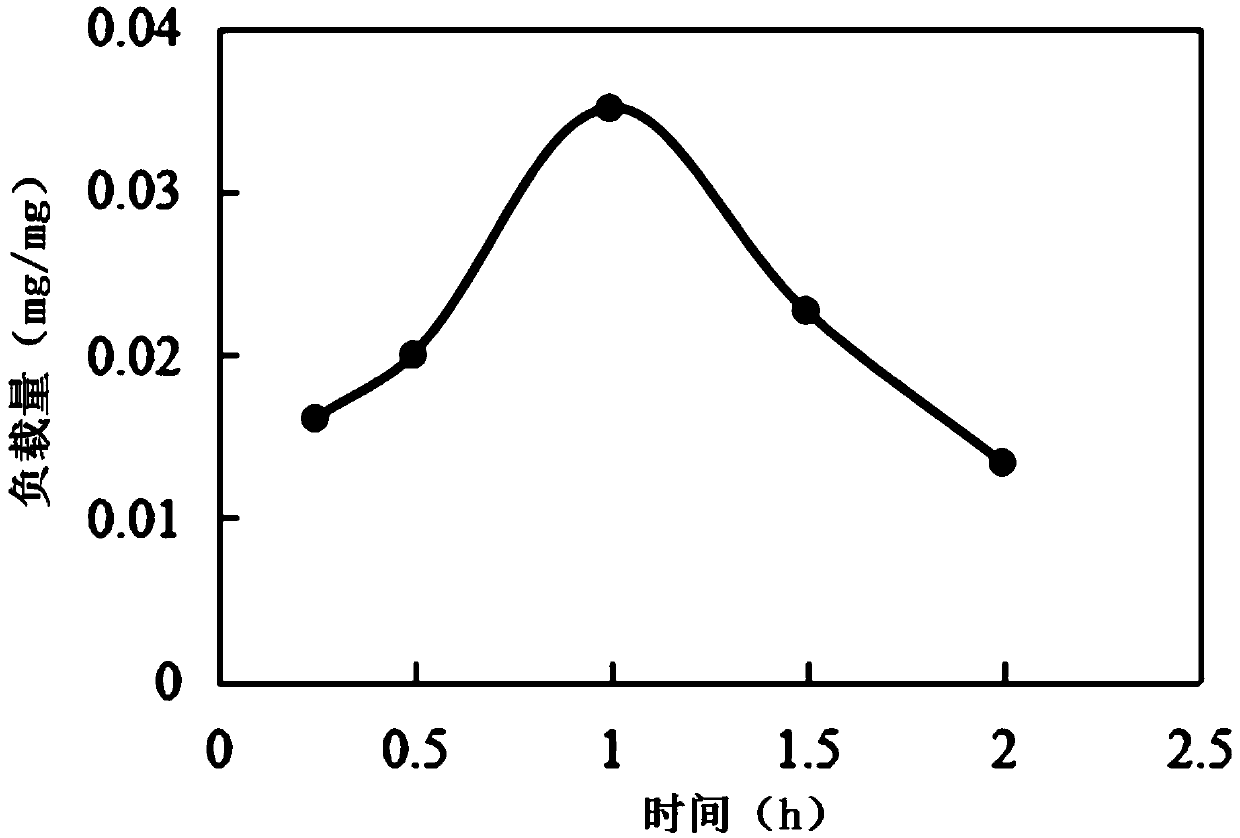

[0040] Step 3: Send the mixed liquid in the entrainer tank to the extraction tank containing the carrier with a delivery pump, adjust the pressure and temperature of the extraction tank, carry out drug loading to obtain a drug-loaded product, and dry the obtained drug-loaded product at room temperature for 22 ~26h, it is completed.

[0041] This embodiment has the following beneficial effects:

[0042] 1. In this embodiment, ...

specific Embodiment approach 2

[0046] Embodiment 2: This embodiment differs from Embodiment 1 in that the carrier in step 2 is GO or CNTs. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0047] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the mass ratio of the drug to the carrier is (1-4):1. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com