High-crisping property baking grease and preparation method thereof

A high-crisping, baking technology, applied in the fields of edible oil/fat, food science, application, etc., can solve the problems of no special high-crisping baking oil and unhealthy baking oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0040] Preparation example one first transesterified oil

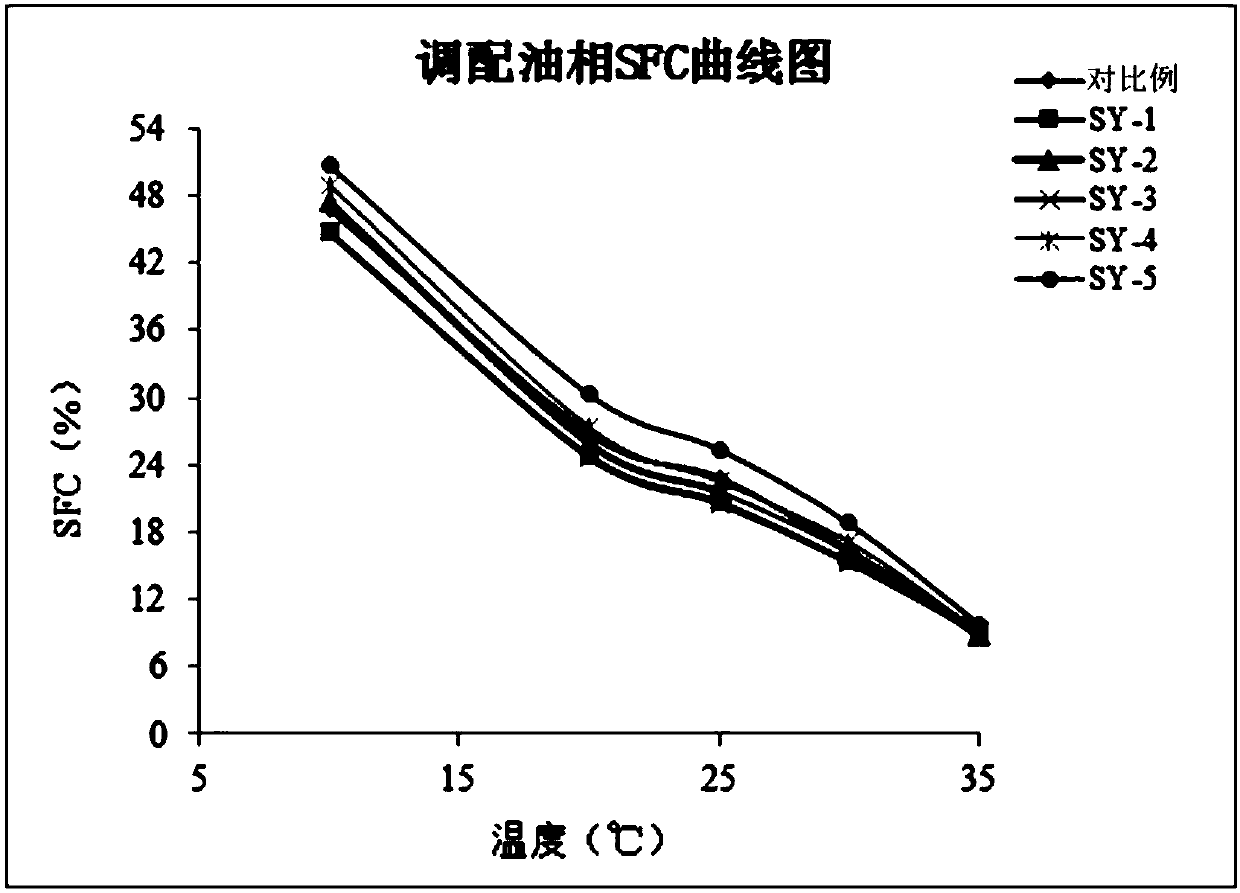

[0041] The palm oil palm oil is transesterified to obtain the first transesterified oil. The SFC of the first transesterified grease at 10°C is 40.96%, the SFC of the first transesterified grease at 35°C is 7.5%, and the SFC values at 20-30°C are all greater than 10%. In the present invention, SFC (Solid Fat Content) is solid fat content, which is the fat content that is solid at a certain temperature.

preparation example 2

[0042] Preparation Example 2 Second transesterification grease

[0043] In terms of mass percentage, 40-50% of palm oil palm oil, 20-30% of palm stearin, 15-25% of tallow and 5-15% of coconut oil are used for transesterification to obtain the second transesterified oil . The SFC of the second transesterified grease at 10°C is 53.68%, the SFC of the second transesterified grease at 35°C is 12.4%, and the SFC values at 20-30°C are all greater than 10%.

preparation example 3

[0044] Preparation Example 3 The third transesterified oil

[0045] In terms of mass percentage, 50-80% of palm stearin and 20-50% of coconut oil are used for transesterification to obtain comparative transesterified oil. The SFC of the third transesterified fat at 10°C is 64.7%, the SFC of the third transesterified fat at 35°C is 16.33%, and the SFC values at 20-30°C are all greater than 10%.

[0046] It can be understood that, in the present invention, conventional transesterification techniques can be used to carry out the above reaction, so the steps of the transesterification reaction will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com