Enhanced wave absorbing material structure body

A technology of wave-absorbing materials and structures, applied in the field of wave-absorbing materials, can solve the problems of poor heat dissipation performance of wave-absorbing materials and inability to take into account wave-absorbing performance, etc., achieve good heat dissipation effect, solve insufficient reflectivity, and good high power resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

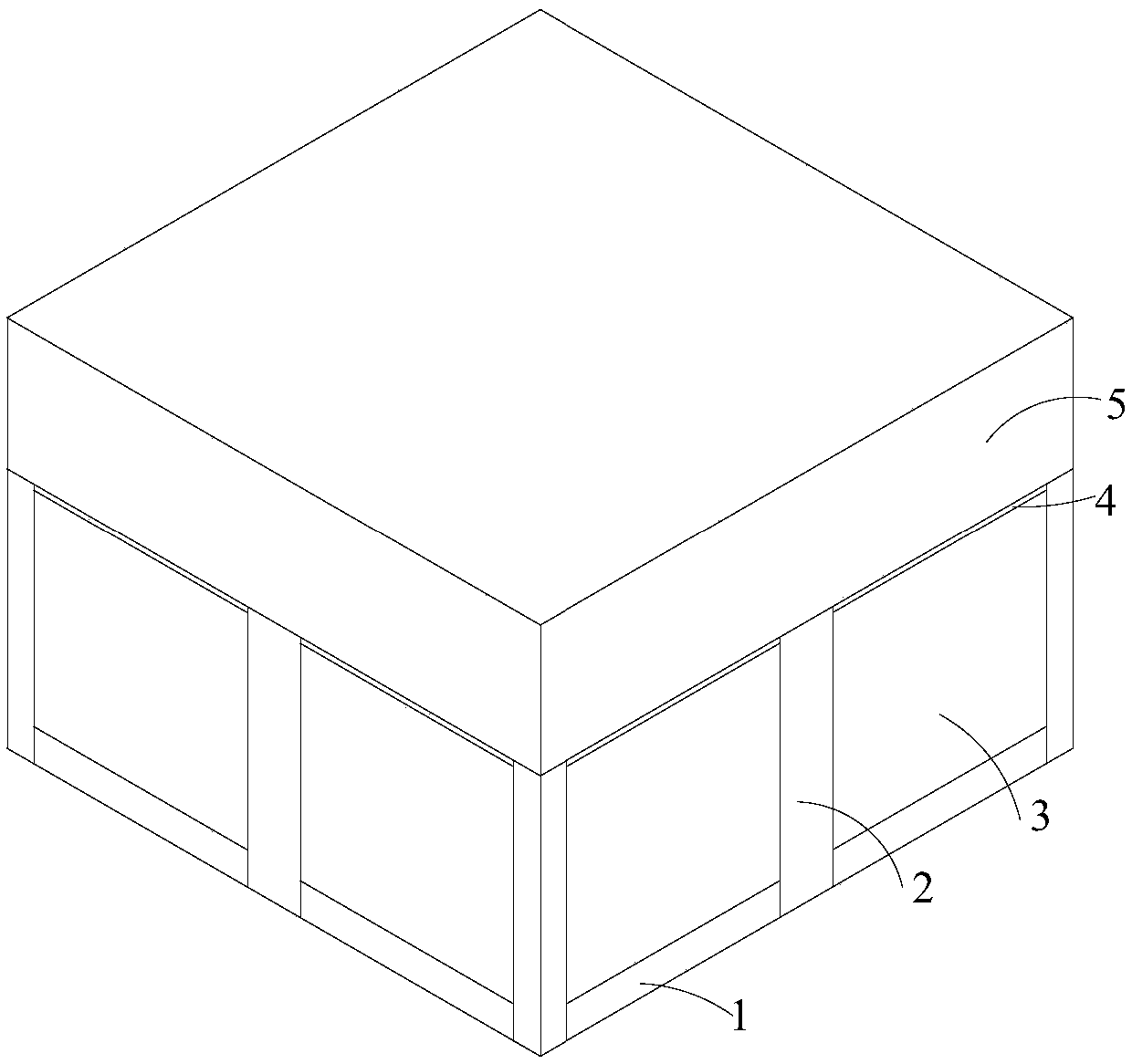

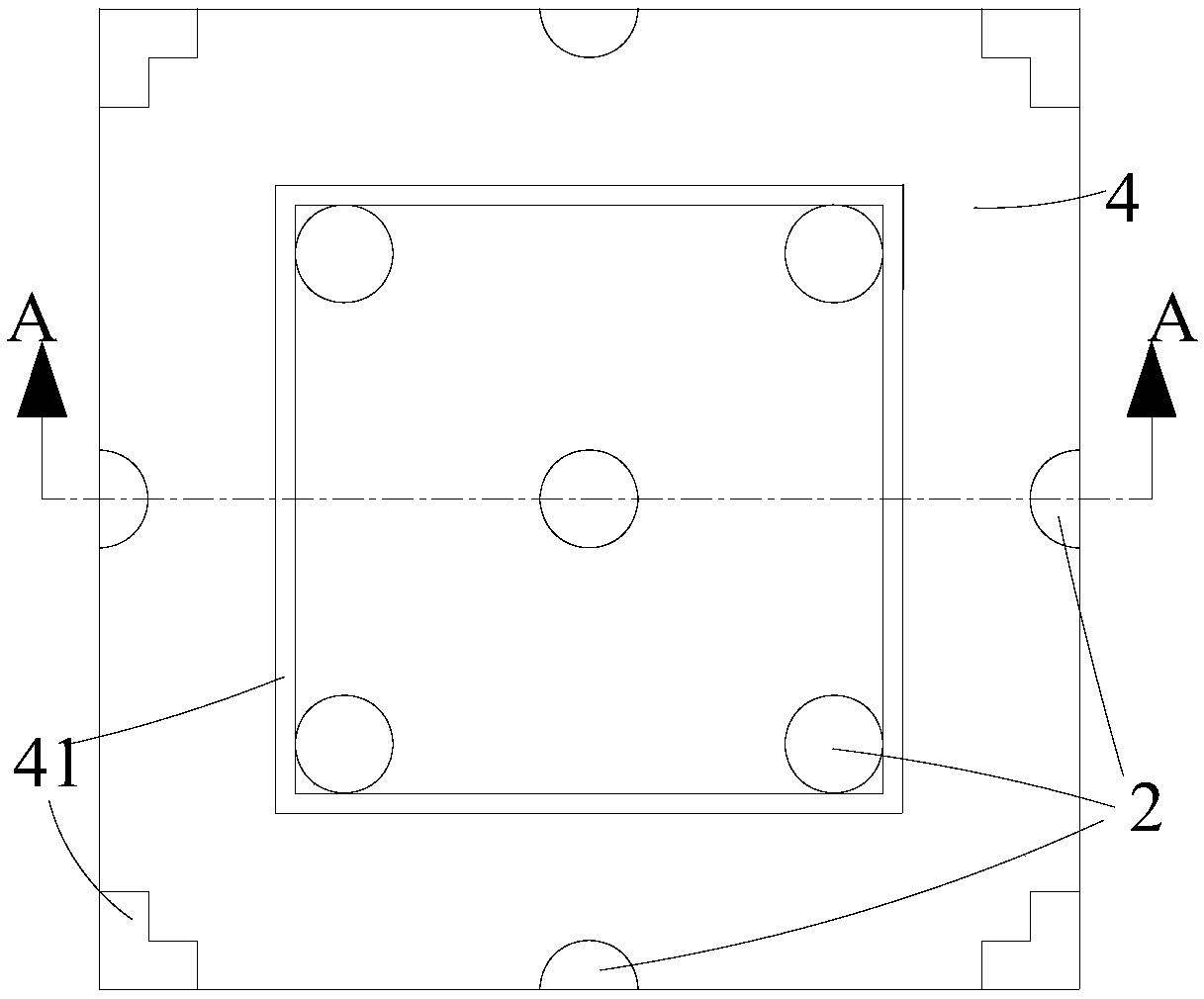

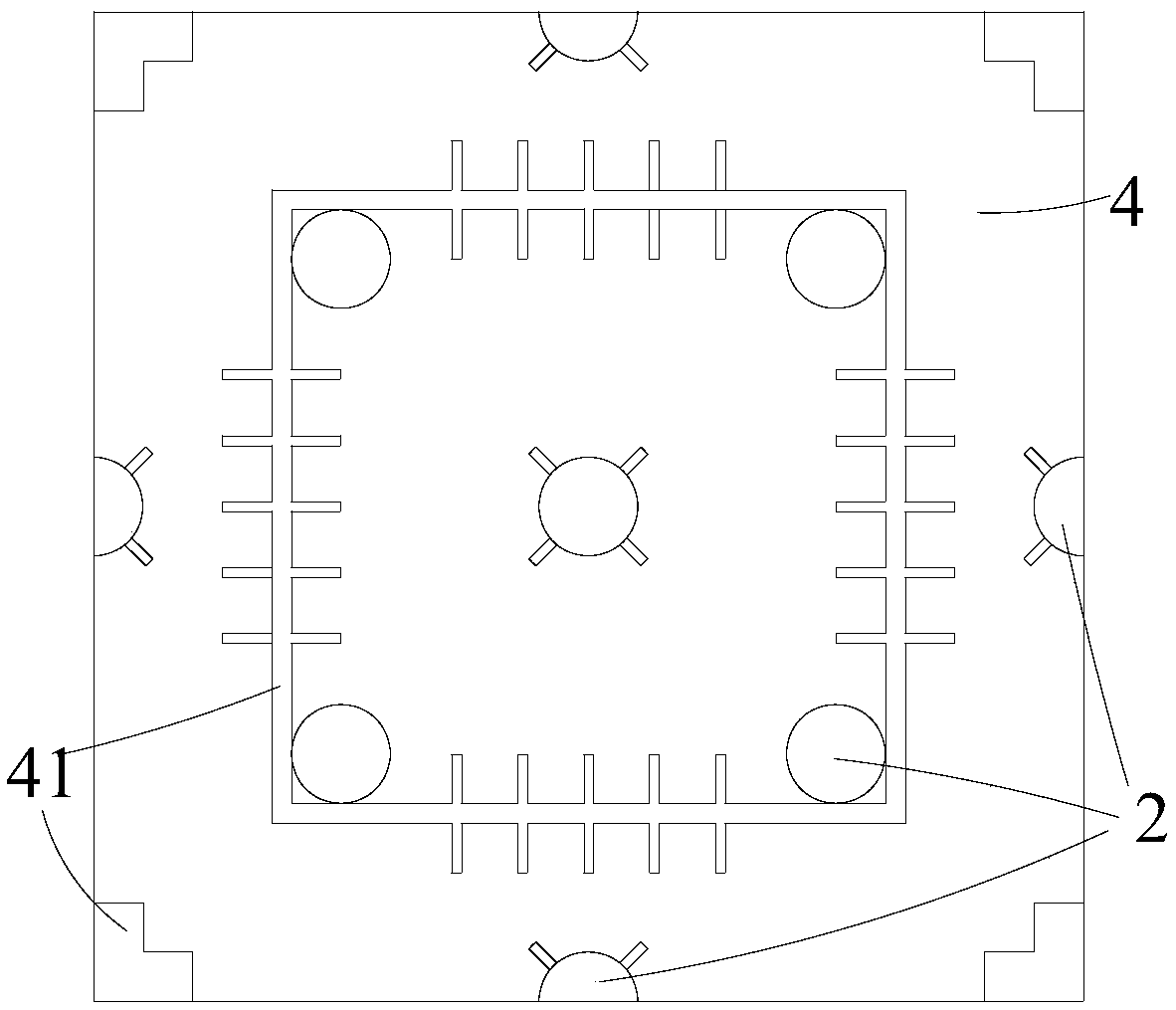

[0061] An enhanced wave-absorbing material structure, the enhanced wave-absorbing material structure is such as figure 1 , 2 , 4, the heat dissipation bottom plate 1 is a copper bottom plate with a thickness of 2mm; the heat transfer body 2 is a copper cylinder (no need to coat a thin layer of copper), and its radius is 1mm; the first wave-absorbing material 3 is an EPP material, Its length and width are 320mm×320mm, and its thickness is 22mm; the carrier board 4 is a PCB substrate board, its thickness is 0.3mm, its thermal conductivity is 0.4w / (m·℃), and its dielectric constant is 4.4; the reflection enhancement layer 41 is copper The foil layer has a line width of 0.5 mm; the second absorbing material 5 is an EPP material with a length and width of 320 mm×320 mm and a thickness of 8 mm.

Embodiment 2

[0063] An enhanced wave-absorbing material structure, the enhanced wave-absorbing material structure is such as figure 1 , 2 , 4, the heat dissipation bottom plate 1 is a copper bottom plate with a thickness of 2mm; the heat transfer body 2 is a copper cylinder (no need to coat a thin layer of copper), and its radius is 1mm; the first wave-absorbing material 3 is an EPP material, Its length and width are 320mm×320mm, and its thickness is 16mm; the carrier board 4 is a PCB substrate board, its thickness is 0.3mm, its thermal conductivity is 0.4w / (m·℃), and its dielectric constant is 4.4; the reflection enhancing layer 41 is copper The foil layer has a line width of 0.25mm; the second absorbing material 5 is EPP material, its length and width are 320mm×320mm, and its thickness is 8mm.

Embodiment 3

[0065] An enhanced wave-absorbing material structure, the enhanced wave-absorbing material structure is such as figure 1 , 2 , 4, the heat dissipation bottom plate 1 is a copper bottom plate with a thickness of 2mm; the heat transfer body 2 is a copper cylinder (no need to coat a thin layer of copper), and its radius is 1mm; the first wave-absorbing material 3 is EPE material, Its length and width are 320mm×320mm, and its thickness is 16mm; the carrier board 4 is a PCB substrate board, its thickness is 0.3mm, its thermal conductivity is 0.4w / (m·℃), and its dielectric constant is 4.4; the reflection enhancing layer 41 is copper The foil layer has a line width of 0.5mm; the second absorbing material 5 is EPE material, its length and width are 320mm×320mm, and its thickness is 8mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com