Preparation method of high yield fluorescent CdS/CdSe/CdS quantum well and preparation method of light emitting diode

A technology of light-emitting diodes and fluorescent quantum yields, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of quantum dot fluorescence quenching, luminous efficiency cannot be realized, nuclear deformation, etc., and achieve the effect of improving external quantum efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

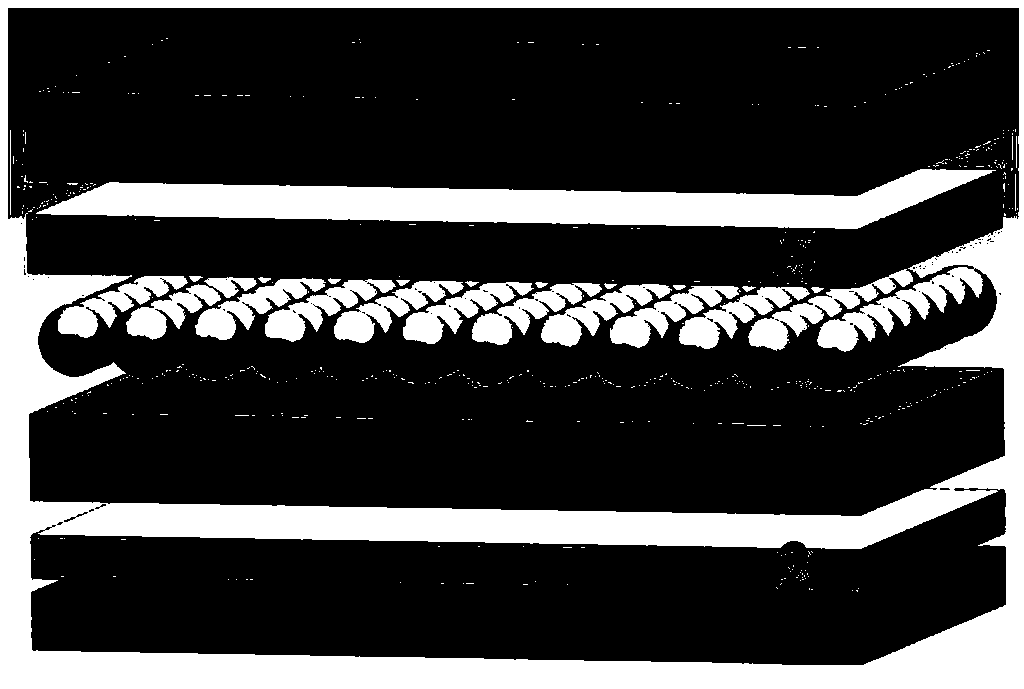

Image

Examples

Embodiment

[0036] 1. Precursor synthesis

[0037] To synthesize 0.5mmol / mL Cd(OA)2, add 5mmol CdO, 5mL OA and 5mL 1-ODE into a three-neck flask, raise the temperature to 150°C, pump for half an hour, and then pass in argon to raise the temperature to 250°C to stop.

[0038] 0.1mmol / mL Cd(OA)2 synthesis, change the amount of CdO, the method is the same as above.

[0039] 2. CdS / CdSe / CdS quantum well synthesis

[0040] (1) To synthesize CdS core, add 9mL 1-ODE and 0.6mL dissolved precursor Cd(OA)2 into the three-neck flask, raise the temperature to 150°C, pump for half an hour, then pass in argon gas to raise the temperature to 270°C, and inject quickly 0.5mL S-ODE (0.25mmol / mL), lower the temperature to 250°C and keep it warm for 10min, stop the reaction, centrifuge the stock solution to remove precipitation, add an appropriate amount of toluene and excess ethanol to the supernatant until the solution is completely cloudy, then centrifuge the solution at this time , take the precipitate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com