Damper fatigue test device driven by linear motors

A linear motor and fatigue test technology, applied in the testing of mechanical components, testing of machine/structural components, testing of vehicle suspension/shock-absorbing mechanisms, etc., can solve the problems of high noise and dependence on shock absorber fatigue testing machines, and achieve Conducive to stability and safety, high work efficiency, and the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

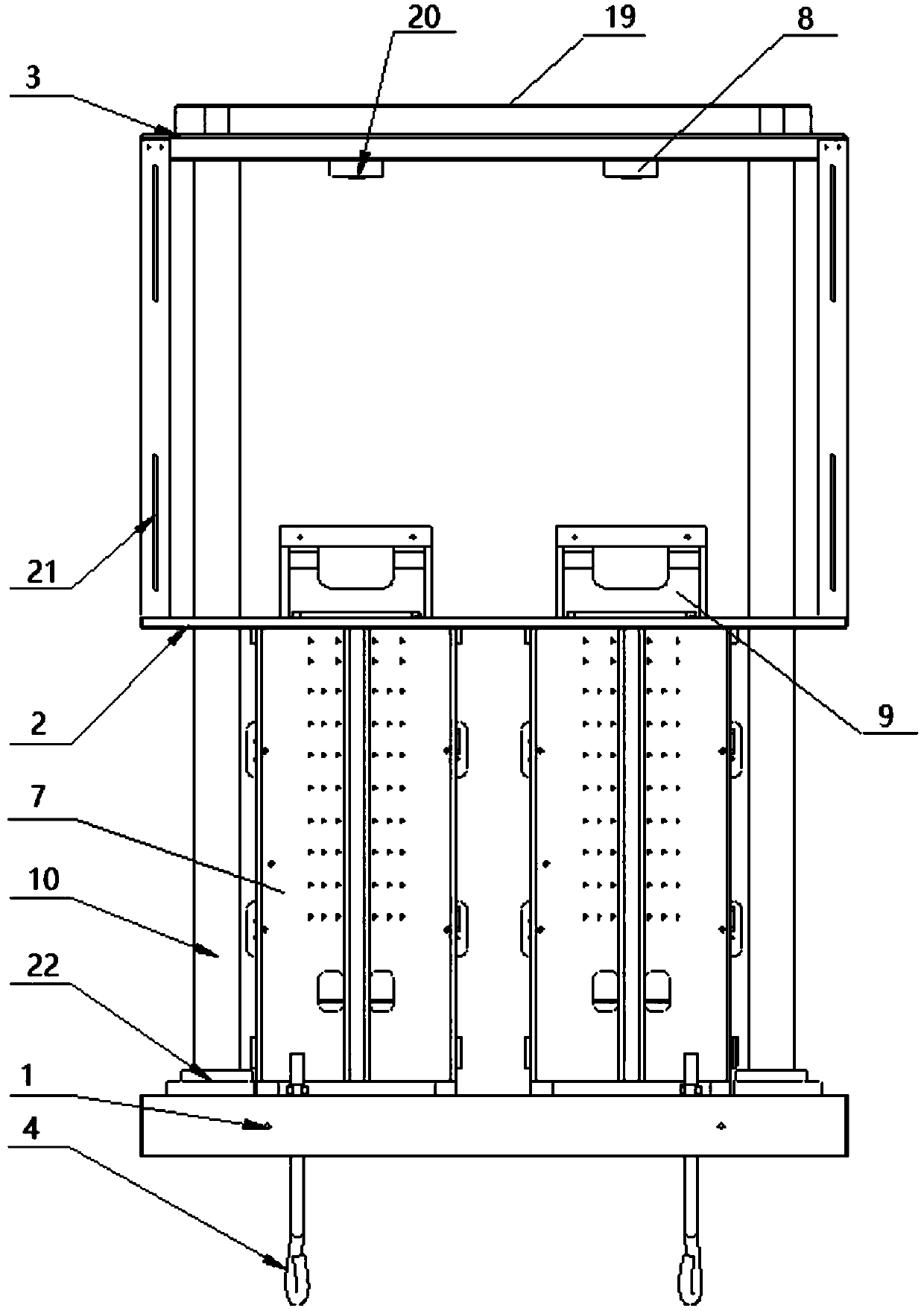

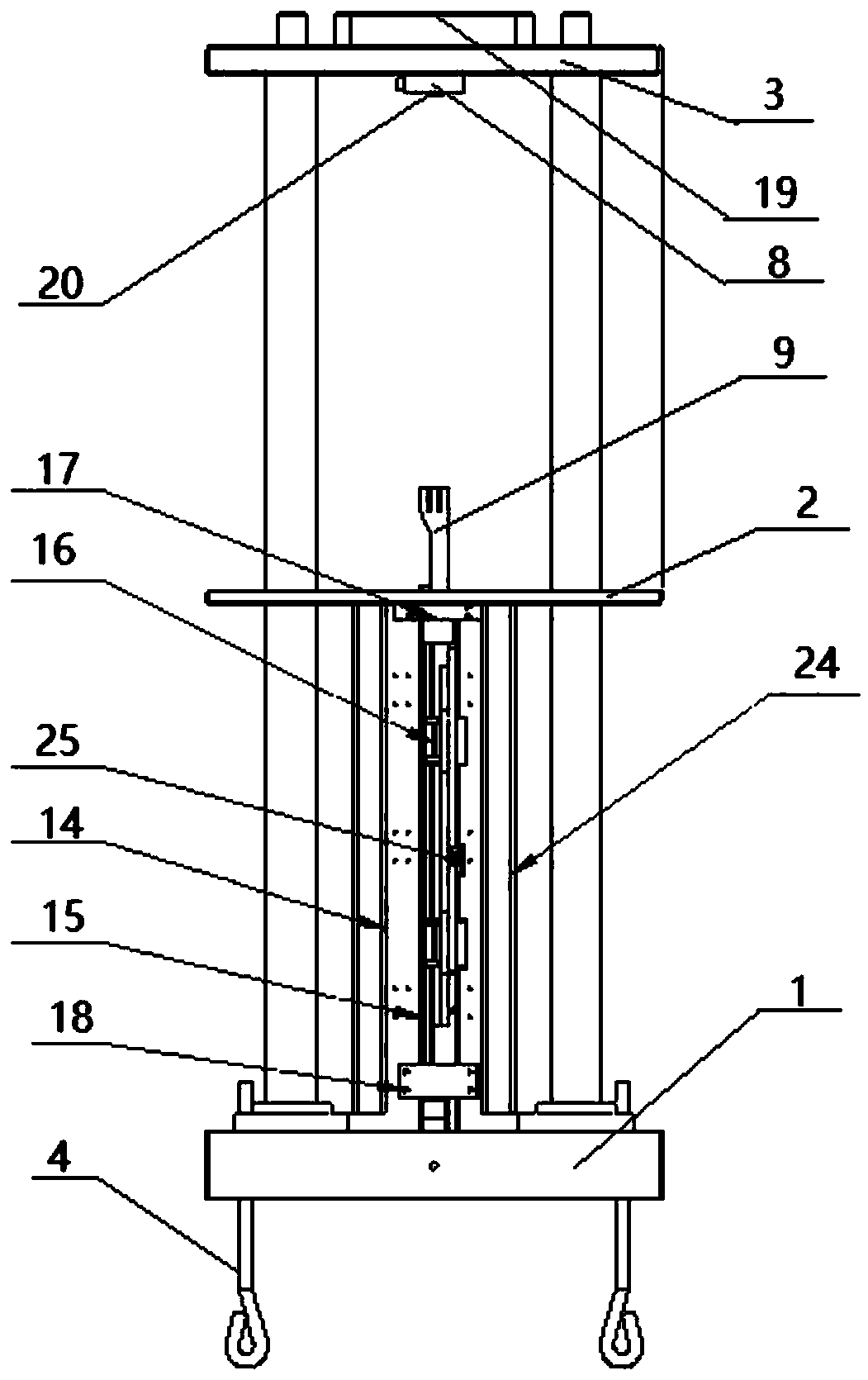

[0031] Such as Figure 1 to Figure 4As shown, a shock absorber fatigue test device driven by a linear motor includes an outer frame, a driving mechanism, a temperature control mechanism and functional accessories. The outer frame includes a base 1 equipped with four anchor bolts 4, a middle partition 2 and The upper end surface is welded with an I-shaped rib plate 19, the lower end surface is provided with a top plate 3 of a force sensor 20, and the bottom of the base is provided with a buffer sleeve 5 with a hollow structure, and the buffer sleeve is filled with 15-50wt% engine oil and 50-85wt% Buffer solution 6 composed of molybdenum disulfide grease; the driving mechanism is installed on the base, and the driving mechanism includes two sets of motion modules 7 in the vertical direction formed b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com