Laser light beam uniformity attenuator

A laser beam and attenuator technology, which is applied in the field of strong laser power density and large multiple quantitative attenuation sampler, can solve the problems that it is difficult to meet the attenuation requirements of high spatial resolution arrays, affect the consistency of laser measurement, and have large differences in attenuation coefficients. Compact structure, good attenuation coefficient consistency, convenient replacement and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

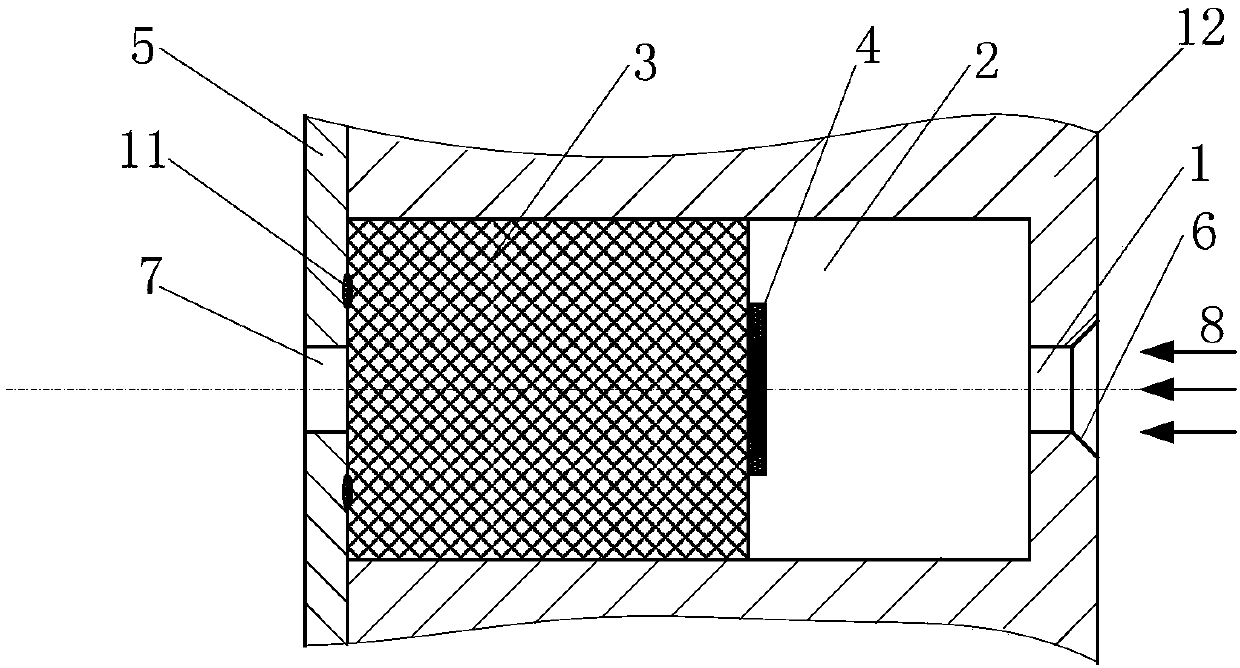

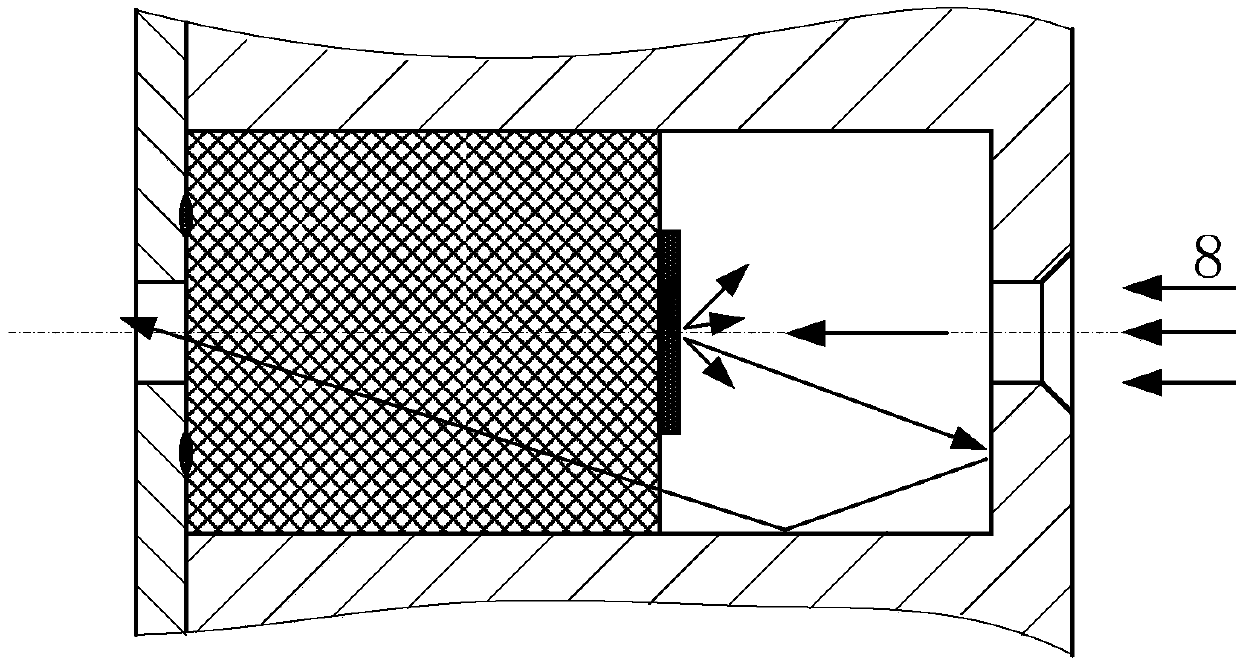

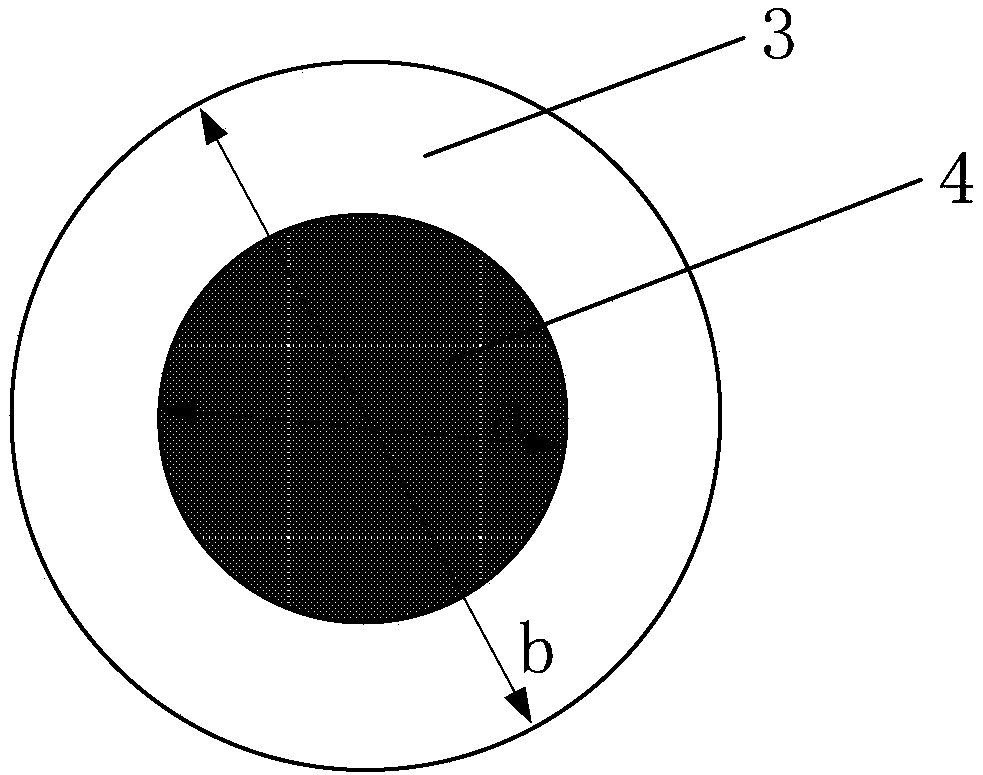

[0033] Such as Figure 1 to Figure 4 As shown, a kind of laser beam homogenization attenuator of the present invention comprises sampling entrance hole 1, attenuation cavity 2 and exit hole 7 that are arranged successively along the laser incident direction, and attenuation cavity 2 is a cavity, and its interior is close to exit hole 7 One end is fixed with a transmissive body 3, the transmissive body 3 is made of white sapphire or quartz glass, which has a high transmittance to the measured laser, and its transmittance is greater than 98%; the middle part of the front surface of the transmissive body 3 is facing the position of the sampling entrance hole 1 A diffuse reflective film 4 with high reflectivity to laser light is arranged at the place, so that the front surface of the transmissive body 3 forms a image 3 Annular clear window shown. image 3 The diameter of the diffuse reflection film 4 is a, and the diameter of the front surface of the transmissive body 3 is b.

...

Embodiment 2

[0038] Such as Figure 5 As shown, this embodiment provides a split attenuator solution. Figure 5 For the structure of fixed attenuation coefficient, the sampling exit hole 7 is set on the fixed bottom plate 5, the attenuation cavity 2 is set in the casing 13, the casing 13 is connected on the fixed bottom plate 5 through the thread 10, and the cavity of the attenuation cavity 2 is provided with The retaining ring 9 that fixes the transparent body 3 relies on the retaining ring to fix the position of the transparent body 3 .

Embodiment 3

[0040] This embodiment provides a split-type attenuator solution with adjustable attenuation coefficient. According to theoretical simulation analysis, the attenuation coefficient of the attenuator mainly depends on the cavity length L, the reflectivity of the inner cavity, and the diameter a of the diffuse reflection film 4 and the transmission The ratio between the surface diameter b of the body 3, so under the condition of the basic structure size and parameter setting, the adjustment of the attenuation coefficient can be easily realized by adjusting the length L of the cavity.

[0041] Such as Figure 6 As shown, the sampling exit hole 7 is set on the fixed bottom plate 5, the attenuation cavity 2 is set in the casing 13, the casing 13 is connected to the fixed bottom plate 5 through the thread 10, and the transmissive body 2 is bonded and fixed in the inner cavity of the attenuation cavity 2 , the beam homogenization attenuator can adjust the length L of the internal cavi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com