Diesel engine DPF cleaning and regenerating device

A technology of regeneration equipment, DPF, applied in mechanical equipment, engine components, machines/engines, etc., can solve the problems of economic loss, reduce DPF particle capture capacity, increase exhaust pipe back pressure, etc., to reduce maintenance or replacement costs , Restore the performance of particle collection and improve the effect of exhaust back pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

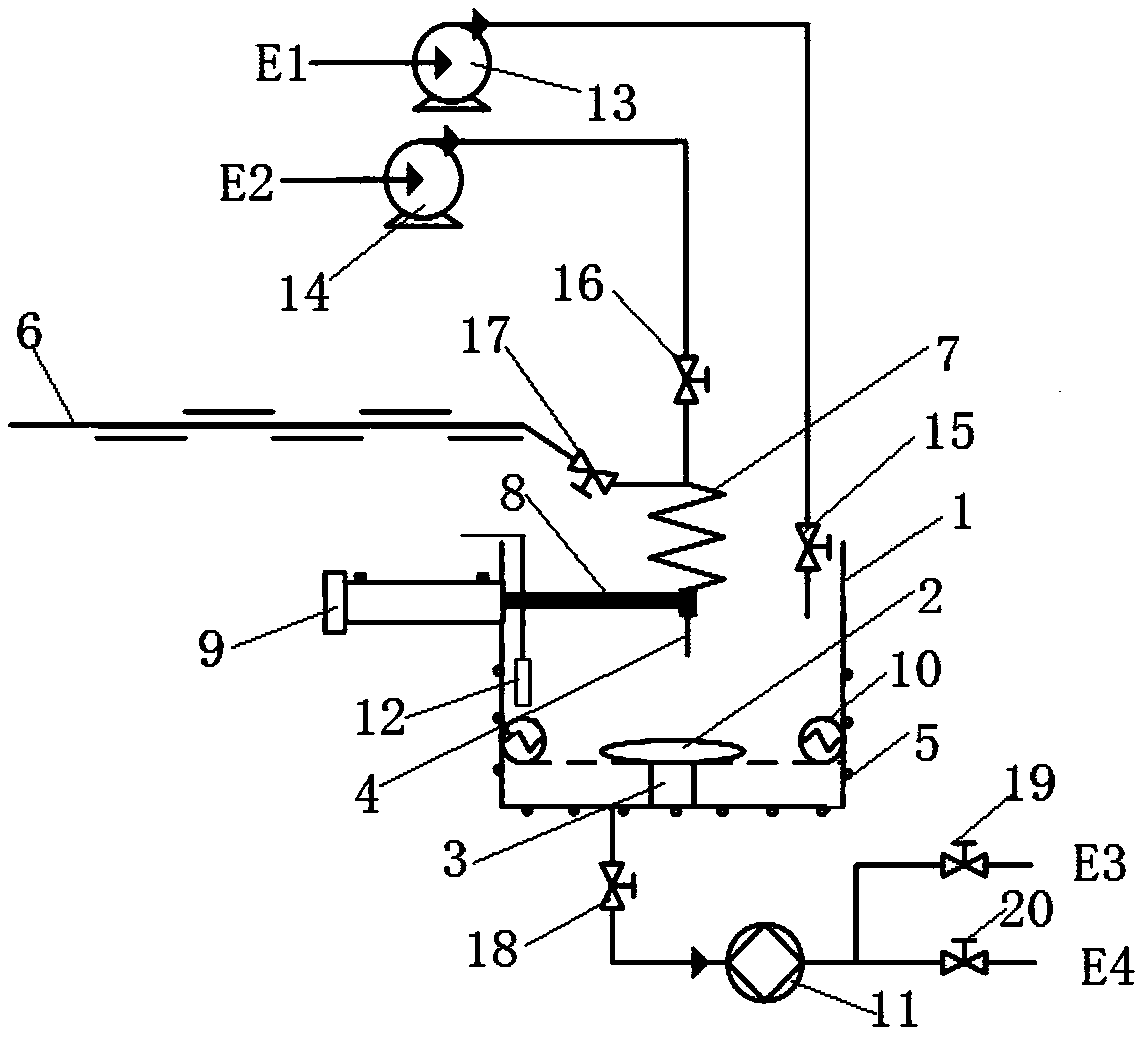

[0015] Such as figure 1 As shown, the diesel engine DPF cleaning and regeneration equipment includes a cleaning tank 1, a cleaning tray 2 built in the bottom of the cleaning tank 1, a cleaning liquid pipeline, a compressed air pipeline 6, a cleaning rod 8, and a rotary transmission for driving the cleaning tray 2 to rotate. 3. The cylinder 9 and the high-pressure nozzle 4 used to drive the reciprocating movement of the cleaning rod 8 are respectively connected to the cleaning rod 8, the liquid outlet of the cleaning liquid pipeline and the air outlet of the compressed air pipeline 6; the bottom of the cleaning tank 1 A drain line is also provided and equipped with a valve 18 .

[0016] The cleaning tank 1 is also provided with an ultrasonic vibrator 5 , a heating and temperature sensing system 10 and a liquid level sensor 12 . In order to ensure a bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com