Construction method of sloping roof using large-span hyperbolic high-wave pressure steel plate

A technology of high wave pressure type and construction method, which is applied to roofs using flat/curved panels, tools for roof engineering, roofing, etc. Economic and social benefits, simple construction, and the effect of scientific design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with reference to the accompanying drawings and in conjunction with embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

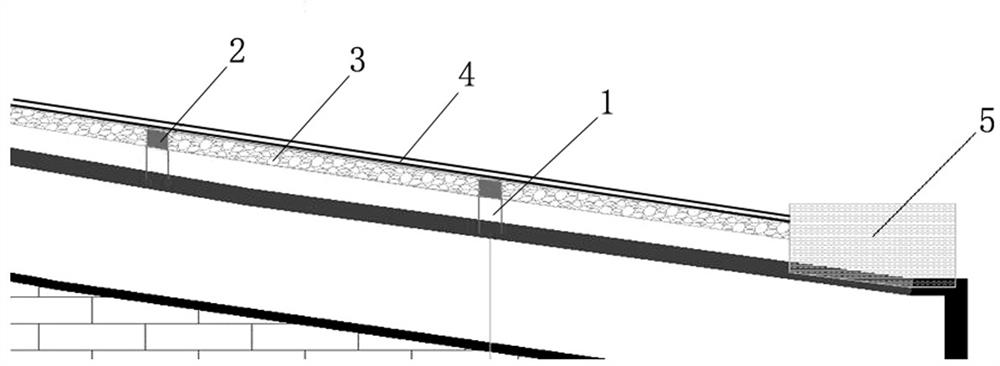

[0025] Such as figure 1 As shown, the present invention provides a slope roof construction method using a large-span hyperbolic high-wave pressure steel plate, comprising the following steps:

[0026] 1) Radian pay-off

[0027] For the construction of hyperbolic setting out, according to the construction drawings, determine the center position of the hyperbolic plane figure and the orientation of the main axis; use the PDCA quality management method, first use the computer to model the structure in 3D, check whether the radian is accurately combined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com