Method for preparing single-walled carbon nanotube fiber and composite fiber thereof

A single-wall carbon nanotube and composite fiber technology, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve problems such as limiting the preparation and performance of composite fibers, limiting practical applications, and complex preparation processes, and achieves high strength and multi-functionality. The effect of high conductivity and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In this embodiment, the method for preparing single-walled carbon nanotube fibers is as follows:

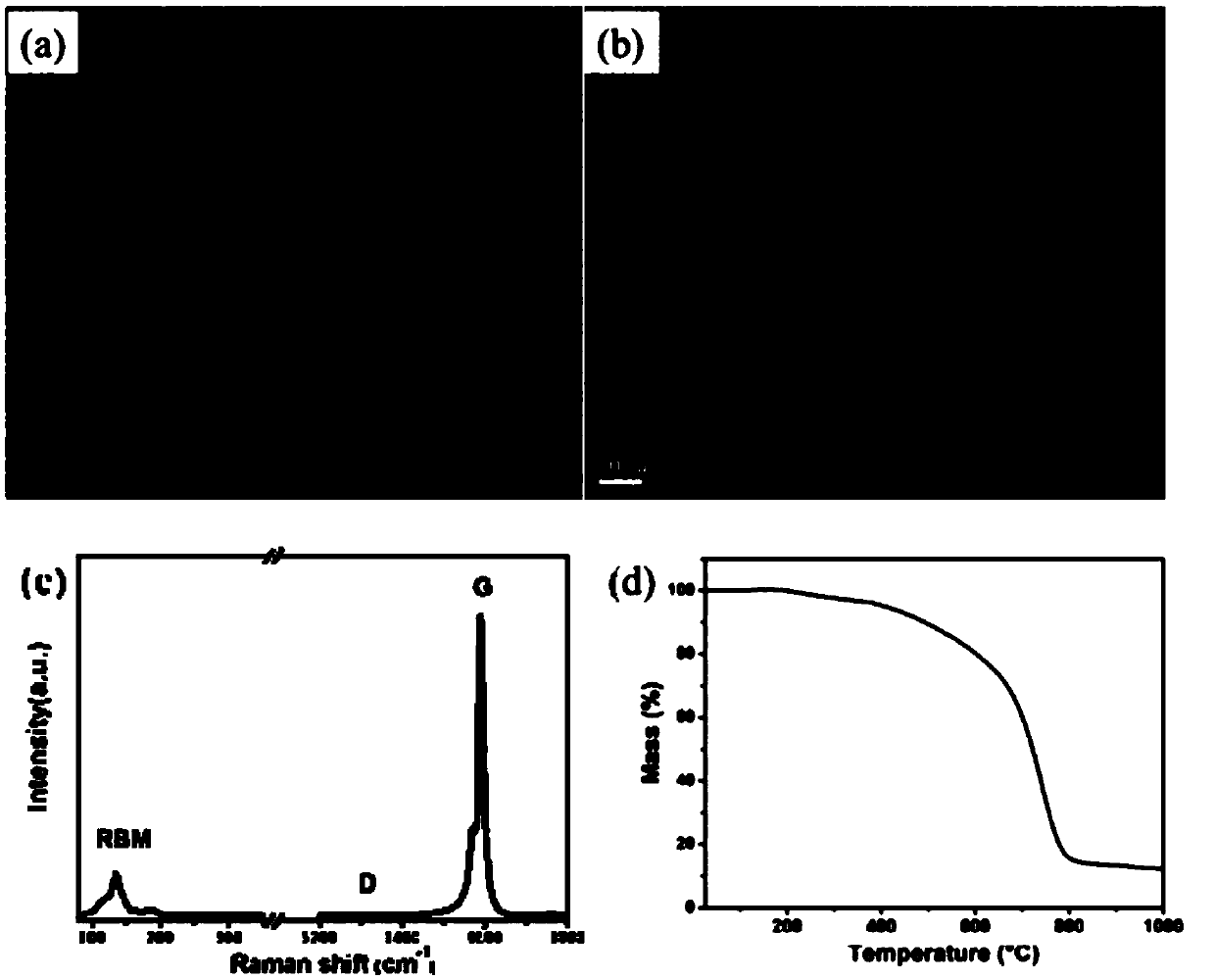

[0047] Preparation of single-walled carbon nanotubes: The preparation temperature is 1200°C, the liquid-phase carbon source, catalyst precursor, and growth promoter are respectively toluene, ferrocene, and thiophene, and the mass ratio of the three is 100:6:1.5. The injection speed is 1.5mL·h -1 , carrier gas H 2 The flow rate is 7000sccm, the gaseous carbon source C 2 h 4 The flow rate is 10 sccm.

[0048] Preparation of spinning stock solution: add single-walled carbon nanotubes and sodium cholate hydrate in water, and ultrasonically disperse in an ultrasonic cell pulverizer for 30 minutes (power 300W) to obtain a dispersion, wherein: the concentration of single-walled carbon nanotubes is 0.2wt%, The concentration of sodium cholate hydrate was 2 wt.%.

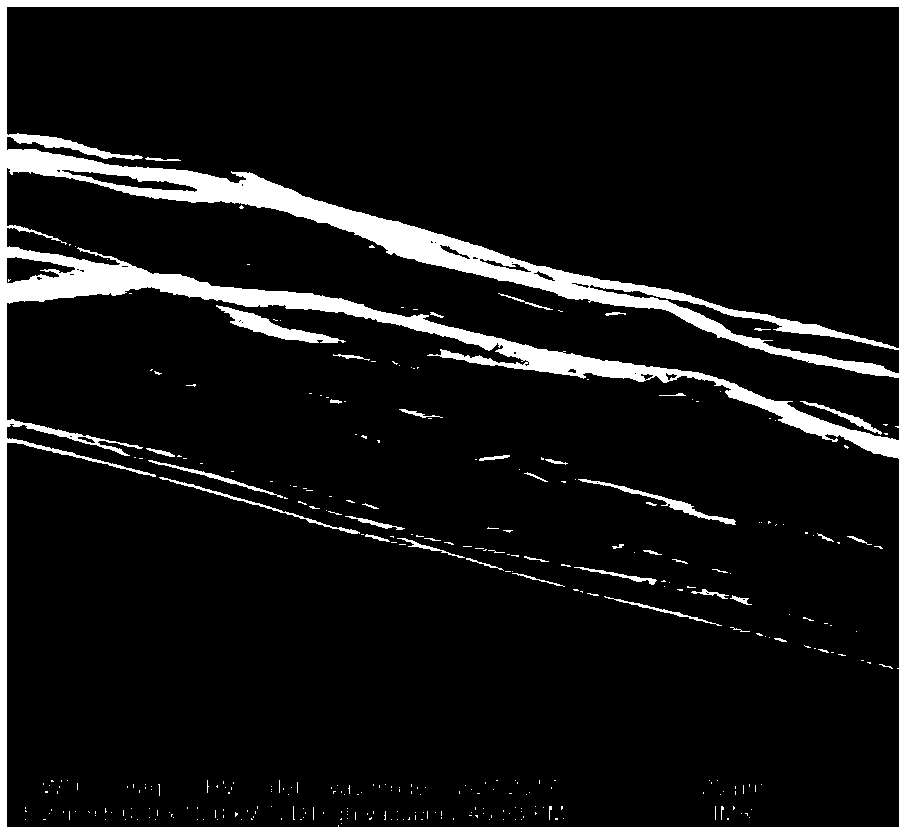

[0049] Fiber spinning process: such as figure 1 As shown, the dispersion liquid is injected from a syringe into t...

Embodiment 2

[0052] In this example, manganese dioxide is taken as an example to demonstrate the preparation of composite fibers and their capacitance properties. The method for preparing single-walled carbon nanotube composite fibers is as follows:

[0053] Preparation of single-walled carbon nanotubes: The preparation temperature is 1200°C, the liquid-phase carbon source, catalyst precursor, and growth promoter are respectively toluene, ferrocene, and thiophene, and the mass ratio of the three is 100:6:1.5. The injection speed is 1.5mL·h -1 , carrier gas H 2 The flow rate is 7000sccm, the gaseous carbon source C 2 h 4 The flow rate is 10 sccm.

[0054] MnO 2 The preparation of sol: (1) add sodium lauryl sulfate (200mg) and H in 500mL deionized water 2 SO 4 (2mL, molar concentration is 1M); (2) Place the above solution in a 90°C water bath and stir for 15min; (3) Add KMnO to the above solution 4 (200mg), continue to stir and react for 1h, the solution gradually changes from purple ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com